Training

In order to be eligible of accessing the EKL facilities, you need to follow the Safety, Introduction & Chemical Course. You can apply to a course only through the NIS system, you can follow the Course Registration Instructions to apply.

Once the Safety & Introduction Course has been passed, in order to start operating the tools in the Else Kooi Laboratory you need to attend tools trainings. Depending on what kind of tools you are going to employ in the cleanroom, you can decide to attend the Process Integration Training (PIT) or different Tool or Module Trainings (MT). You can apply to a training only through the NIS system, you can follow the Training Registration Instructions to apply.

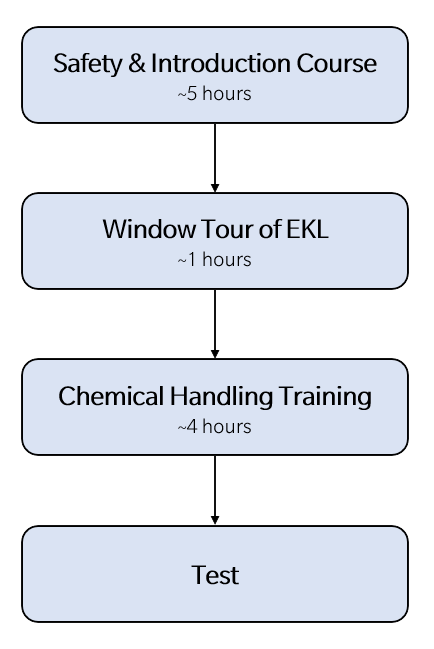

Safety, Introduction & Chemical Course

Any cleanroom or lab user, either from the TU Delft or from other organisations, must attend and pass the Safety, Introduction & Chemical course. You can to register to this course only through the NIS system. This course provides general guidelines for laboratory work with chemicals. It includes hazards, prevention, emergency response, how to recognize and understand chemical labels and information forms called Material Safety Data Sheets (MSDS).

The topics discussed in the Safety & Introduction course are:

- Cleanroom behaviours;

- Cleanroom ethics;

- Gowning and Un-Gowning;

- Wafer handling;

- Equipment policy;

- Contamination prevention;

- Safety rules.

The topics discussed in the Chemical Handling course are:

- Planning chemical experiments

- Chemical risk management

- Safe handling of chemicals

- Classification and labelling of chemicals

- How to handle chemicals spills

- How hazardous chemicals can affect the body

- How to dispose chemical waste

- Storage of chemicals

- Introducing a new chemical in the CBL

- Usage of fume hoods/wet benches

- Incident management (emergency response in case of chemical incidents)

At the end of the courses a test will be performed. After passing the test, the access to cleanroom will be granted. To get tools rights additional training will be needed.

Training method: Videos/hands-on

Duration: 1 and ½ days

Frequency: Once a month

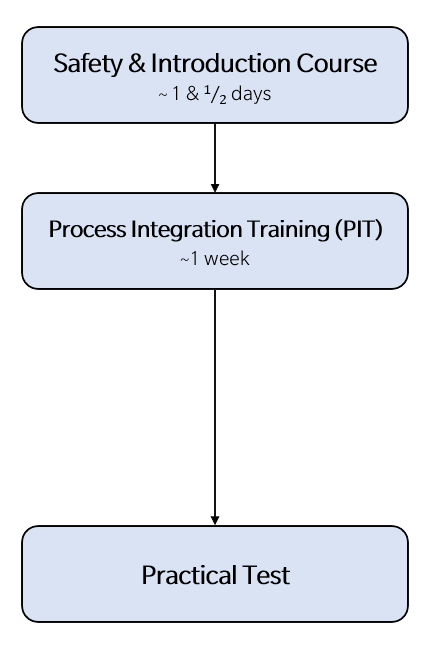

Process & Integration Training

If you need to execute a complex process flowchart to fabricate your device in the EKL CR100, then the EKL Process Integration Training (PIT) is the best solution. You can to register to this training only through the NIS system.

The following equipment modules are included in the PIT course:

- Lithography (stepper & coater/developer)

- Wet chemistry (wet benches)

- Plasma etching of dielectrics and metals

- Furnaces

- PECVD deposition of dielectrics

- Sputter coating of metals

- Thin film layer thickness measurement

This course covers all the parts of the basic manufacturing process. Besides training on the most important and most used equipment, it also includes hands-on wafer handling practice and basic processing knowledge, as well as useful tips for obtaining the best process results.

Prerequisite: Introduction and Safety training

Training method: Videos/hands-on

Duration: 3-5 days

Frequency: On request

Max 3 participants/group

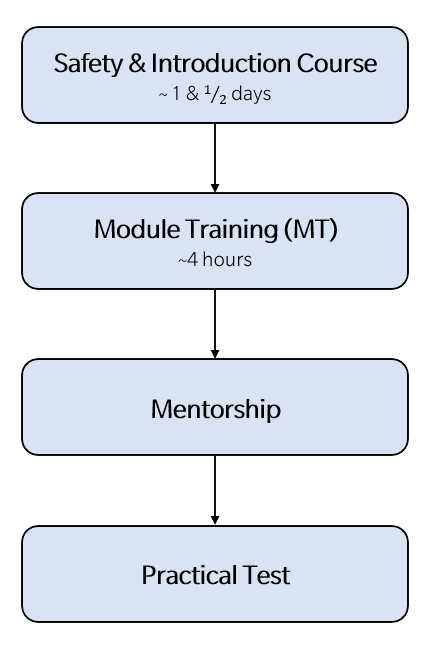

Tool or Module Training

Users that need to perform any activity on EKL equipment have to sign up for module training in the NIS system. To get a Tool or Module Training you need to:

1. Attend the training session: During the session, the trainer will show the basic operation, proper usage, application, and "do’s and don’ts" of the tool. Users are encouraged to bring their own samples to the training sessions. These will be processed during the training. Sessions for each piece of equipment are on an as-needed base.

2. Practical Test: After attending a training session a user is allowed to operate the machine with the help of authorized research group members or colleagues. When the user feels comfortable and confident enough to operate the equipment independently, then an appointment with the trainer must be made to be tested. Once the trainer is fully satisfied with the user’s knowledge and ability, then the user will be added to the "qualified users" list in the NIS system. This allows the user to operate the tool independently and to make equipment reservations.

Prerequisite: Safety and Introduction training

Training method: Online (videos)/hands-on

Duration: 1-4 hours

Frequency: On request

Max 3 participants/group