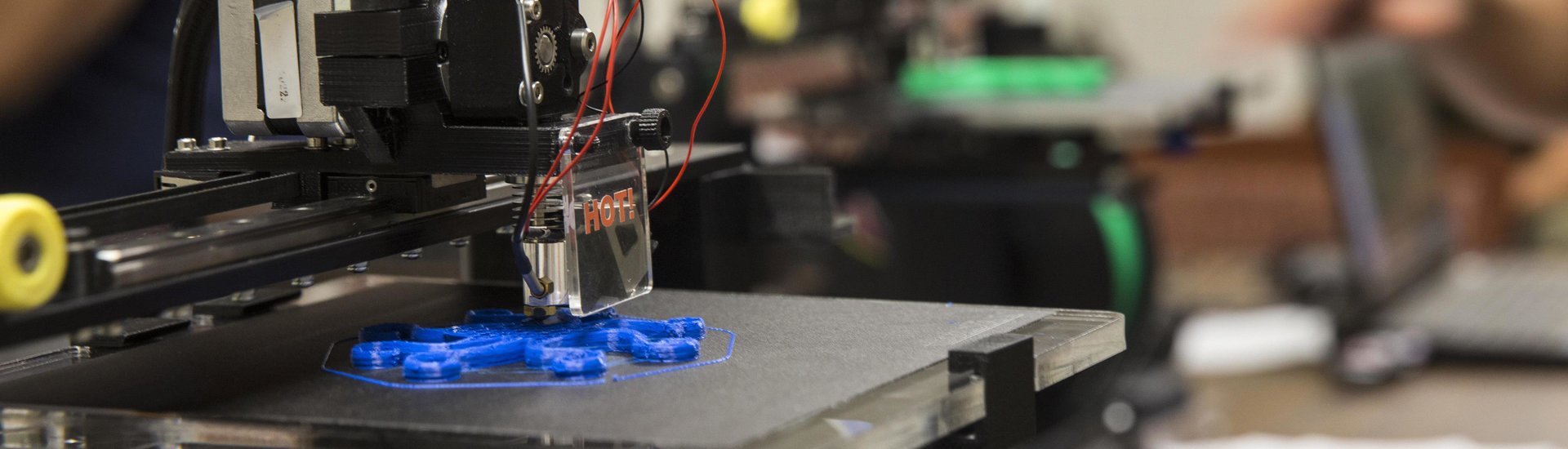

Joining and Additive Manufacturing

Joining is critical to constructions ranging from micro to macroscopic length scales. This research theme focuses on welding, with particular emphasis on the effects of imposed thermal and mechanical conditions on the resultant structure and properties of materials, as well as the behaviour and control of joining processes.

Current areas of activity include:

- microstructure development – measurement and phase field simulations

- prediction and measurement of stress fields and associated distortion

- fluid flow and flow stability of liquid metals

- hot cracking – microstructural influences on crack initiation

Applications range from mulit-pass welds in additive manufacturing to resistance spot welding of high strength automotive alloys. Welded microstructures are generally examined after completion of a weld and provide an indication of likely performance (mechanical, electrochemical etc.) of a weld. Our research also extends to the in-situ development of the microstructure, for which synchrotron based X-ray diffraction is employed, together with numerical (phase field) simulations.