Metals and Sustainable Development

The aim of the research is to develop understanding of the behaviour of metals at the level of the microstructure, with a focus on steel, when subjected to conditions of elevated temperatures, mechanical loading, radiation and combinations thereof. These conditions occur both in the manufacturing phase and in the use phase of the materials life cycle. The research approach is to combine experimental evidence and physics-based modelling at different length scales. Relevant microstructural processes are phase transformation, precipitation, recrystallisation, texture formation, dislocation network evolution, development of radiation damage and mechanical damage, and others, on which we develop fundamental understanding.

The industrial collaborations of the group are extensive due to the extensive societal applications of steel. Prominent examples are transport (automotive, rail, maritime), energy (wind, nuclear), steel production, and high-tech constructions.

Publications

Research

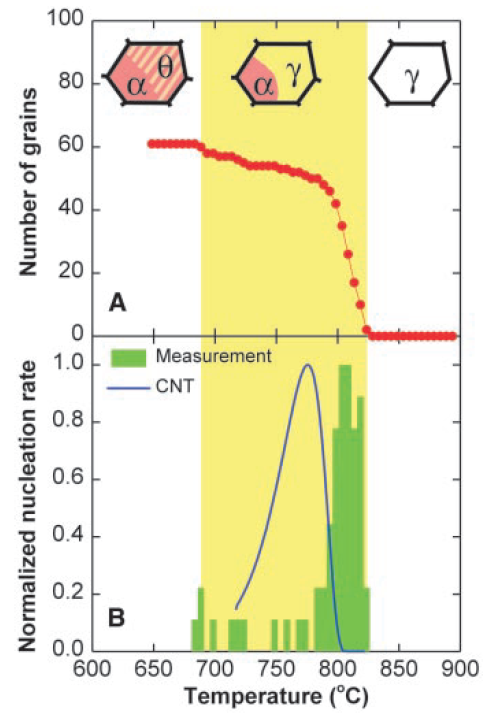

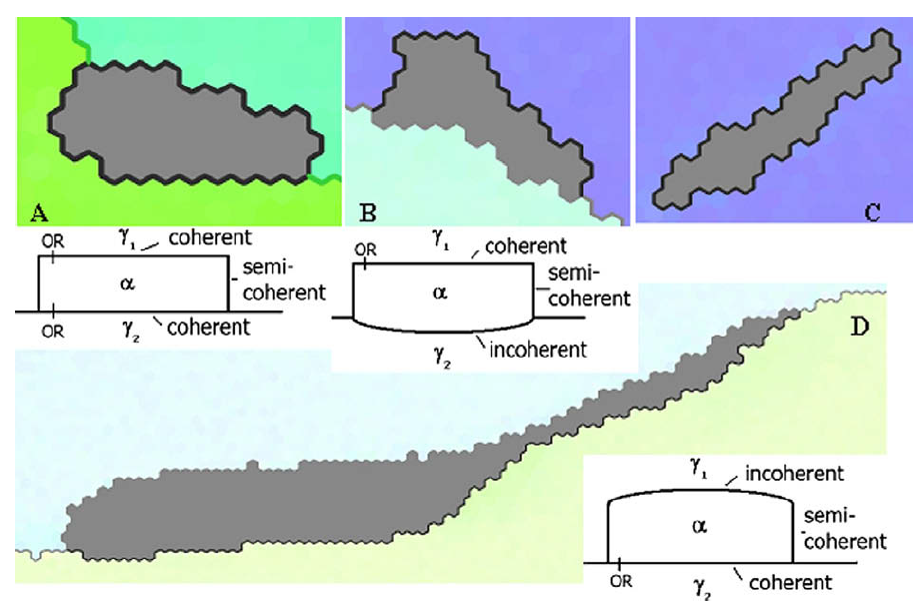

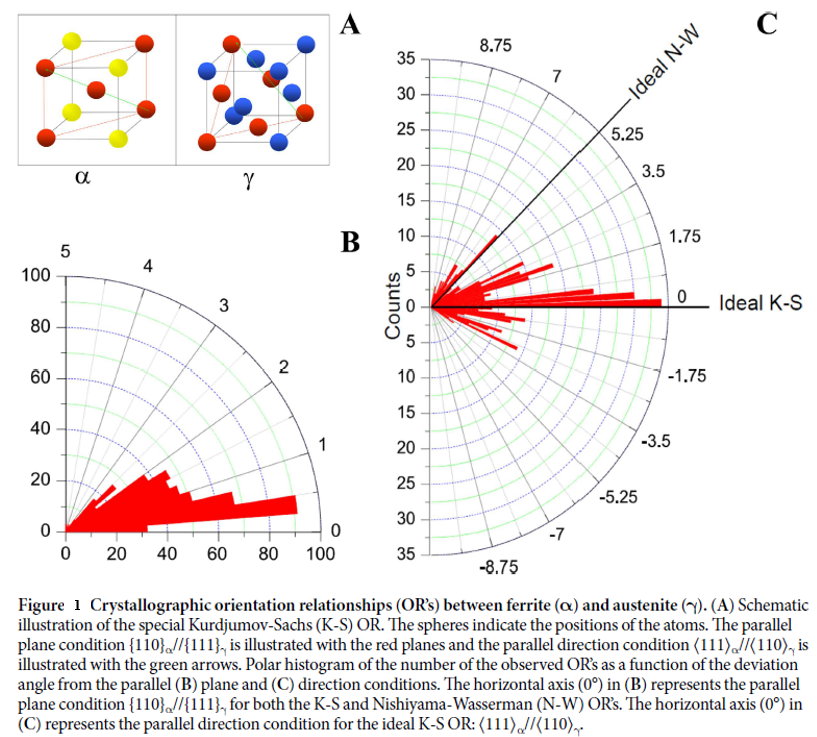

The underlying mechanisms of solid-state nucleation in steels can be considered both an intriguing and a societally relevant subject of study. We observed that ferrite nucleation in steel takes place much quicker (with lower activation energy) than predicted by critical nucleus models based on the classical nucleation theory (CNT), see Fig. 1 [Offerman et al, Science 2002]. Further research showed that BCC (ferrite) nuclei (grey in Fig.2) often have special crystallographic orientation relationships (OR’s) with FCC (austenite) grains as observed with 2D-EBSD in a special alloy of Fe-Cr-Ni [Landheer et al, Acta Mater 2009]. We also observed special OR’s between austenite nuclei and neighbouring ferrite grains in 3D in steel at elevated temperature with 3DXRD microscopy at a synchrotron source, see Fig. 3 [Sharma et al, Scientific Reports 2016]. Over a period of 14 years - and thanks to grants of the Dutch Research Council NWO, M2i and continuous support from Tata Steel - we have shown that the activation energy for nucleation becomes lower (and therefore nucleation takes place faster) in case the nucleus has more special crystallographic orientation relationships with its neighbouring parent grains, see Fig. 4 [Sharma et al, Scientific Reports 2016]. Currently, these fundamental insights are now finding its way to the steel industry via the Digitally Enhanced New Steelmaking (DENS) programme in which we work together with Tata Steel to accelerate the development of new steel grades for lightweight automotive applications.

A second example of fundamental research that found its way to industry is the work for which we received the Sawamura award from the Iron and Steel Institute of Japan for ‘important contributions in both of the academic and industrial aspects’. We received this award for our experimental and theoretical work on the random formation of titaniumcarbides during tempering of martensitic steel [Ohlund et al, ISIJ 2014]. This work was performed in collaboration with fastener company Nedschroef in relation to their ultra-high-strength fastener development for lightweight automotive applications.

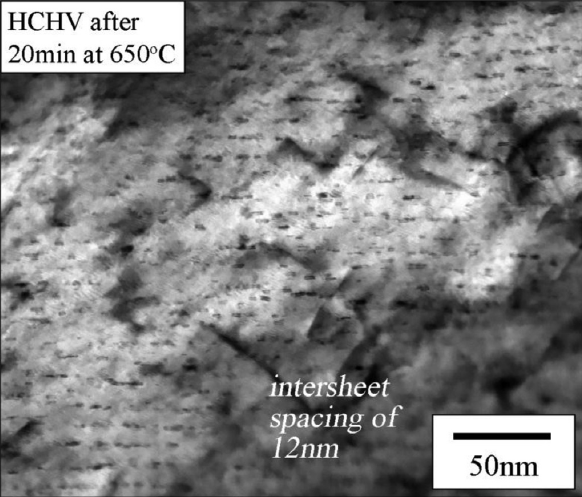

A third example of fundamental research that found its way to industry is the work for which we received the Vanadium award (2019) of the Institute of Materials, Minerals and Mining (IoM3). In this work we study the interaction between interphase precipitation and phase transformation kinetics in steel [Ioannidou, Acta Mater. 2019]. Beautiful rows of vanadiumcarbide precipitates can be observed in the TEM and atom probe tomography on the length scale of nanometers in steel, see Fig.5. We use in-situ small-angle neutron scattering (SANS) in order to obtain good statistics about the precipitate number density and size distribution. We do this in collaboration with colleagues of the department of radiation science and technology and colleagues at the LARMOR instrument of ISIS in the UK, see https://www.tudelft.nl/tnw/over-faculteit/afdelingen/radiation-science-technology

https://www.isis.stfc.ac.uk/Pages/Larmor.aspx

It is fascinating to see that industrially produced steel strips having lengths of tens of meters, while the precipitates are locally arranged in highly ordered structures on the level of nanometers. As a result, the steel has special properties: high strength combined with high local and global formability. This is needed for intricately shaped parts that are used in cars, e.g. suspensions. Using high-strength steel reduces the weight of vehicles and saves fuel and/or batteries.

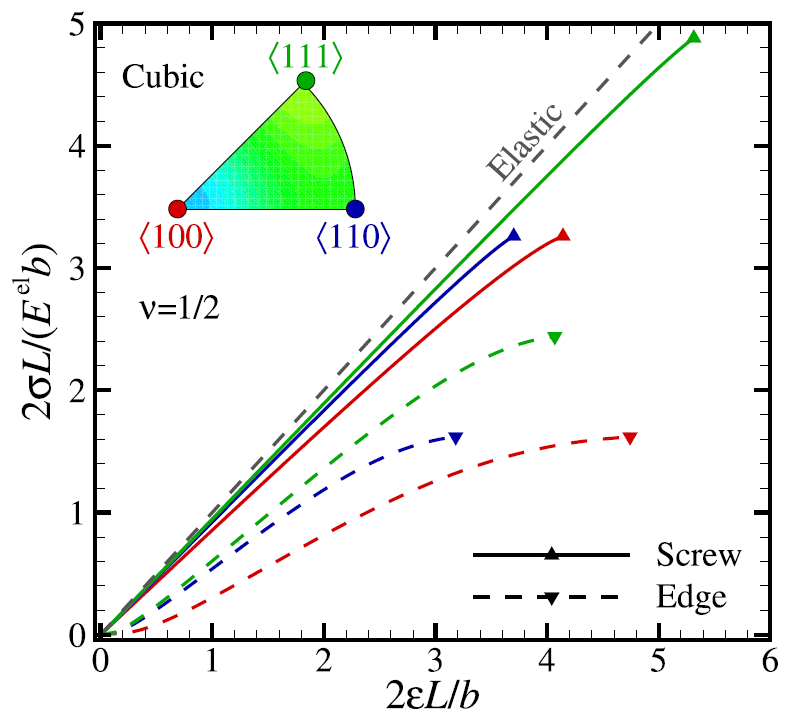

Controlling the mechanical properties of metals requires a thorough understanding of the dislocation network. In our recent work, we have theoretically investigated the effects of dislocation network geometry on the pre- and at-yield mechanical behaviour of metallic single crystals [Van Dokkum, Materialia 2021]. It turns out that the dislocation character has major effects on both the apparent elastic constants and yield points. Figure 6 shows the normalized stress as a function of the normalized principal strain in case the tensile stress is applied in the <100>, <110> and <111> directions of a single crystal with cubic symmetry and Poisson’s ratio of ½. The stress strain behavior depends on the direction of the applied stress and the initial character of the dislocations, i.e. edge or screw dislocations.