Biobased Debondable Adhesives (BiDebA)

Aim

This project seeks to reduce the environmental impact associated with traditional adhesives and to foster a new era of sustainable and recyclable product design. Revolutionizing the use of adhesive in industrial applications through the development of innovative, biobased, debondable solutions.

TU Delft's Contribution

The TU Delft research group Art and Archaeology - Team Langejans - (TUD) applies the past to better the future. TU Delft's contribution consists of identifying historically inspired adhesives and additives with the required material properties for the final demonstrator.

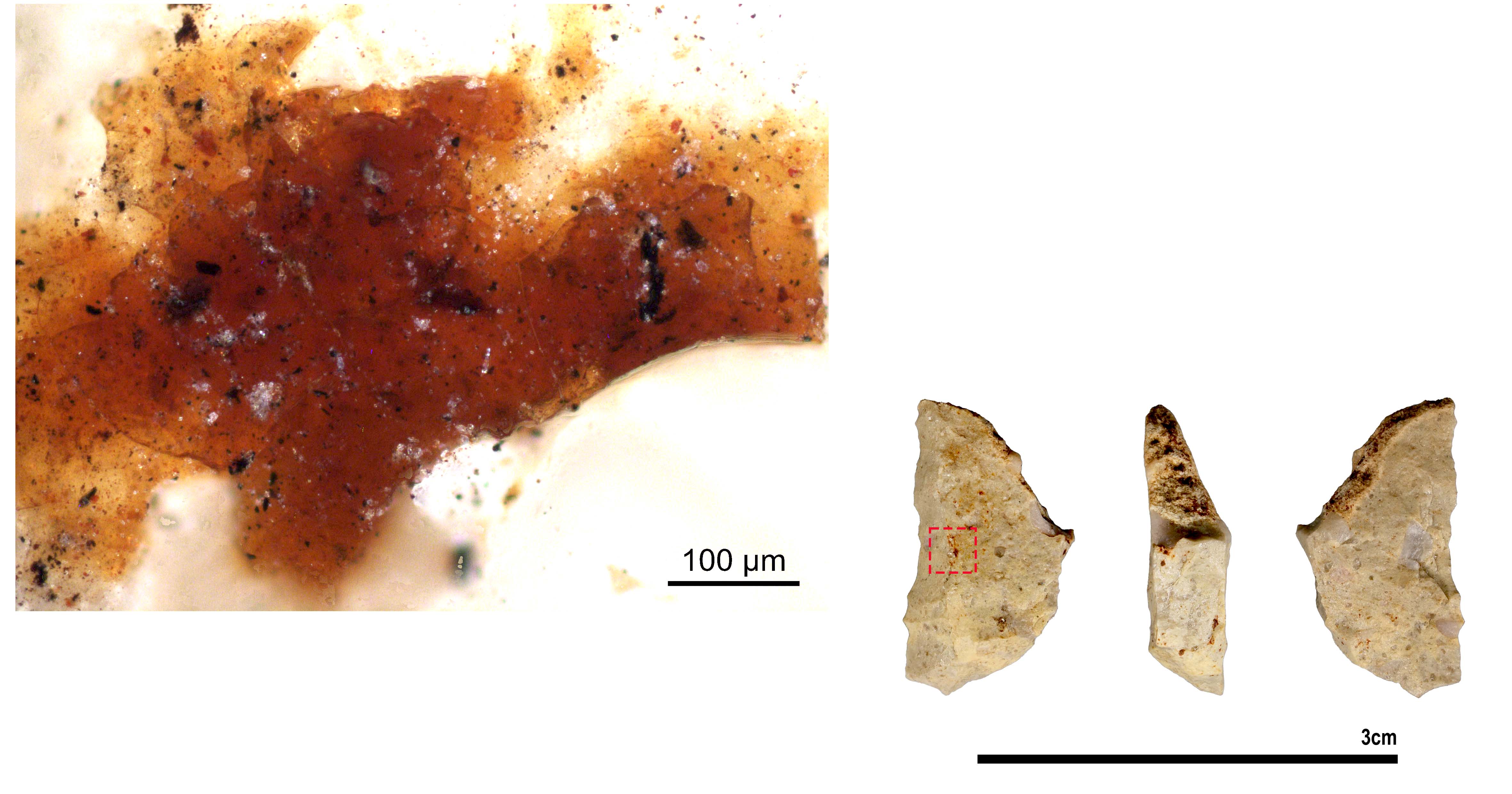

Based on current knowledge, the most promising candidates for tackifiers are tree resins and tars, while iron oxide and manganese oxide are considered potential additives. Our ancestors already used ochre (iron oxide) to manipulate adhesive properties, and the use of iron oxide to enhance debonding and facilitate recycling may date back as far as 200,000 years. There could be even more ancient metal or mineral-based additives. However, it remains unclear which ratios and tackifiers would optimize the performance of these additives in modern applications. Therefore, further research is necessary.

Funding

Total Project Budget: €794K EU Funding: €476K

Partners

Timeline

2023 - 2025