Lawine

Technology and services are developed to use LIDAR systems in offshore wind power plants to significantly reduce the cost of energy:

- better estimate of wind resource

- efficient power performance assessments

- optimising turbine control

- reduction of mechanical loads in wind farms

Development and analyses with LIDARS, forward looking LIDARS, LIDARS coupled with turbine control and this project includes the Dutch contribution to the international windscanner.eu facility.

TU Delft contribution

- Performance of LIDAR measurements in front, around and at the back (wake) of a wind turbine. The LIDAR will be ground based or nacelle mounted on the research wind turbines at ECN’s test site.

- Analysis of the data from the LIDAR measurements of point 1. The mean wind speed at several heights should be obtained (i.e. wind shear). Furthermore, the atmospheric stability should be determined; if required additional remote sensing equipment should be applied for this purpose. Finally, in cooperation with the LIDAR manufacturer (Avent Lidar Technology), information on turbulence should be acquired.

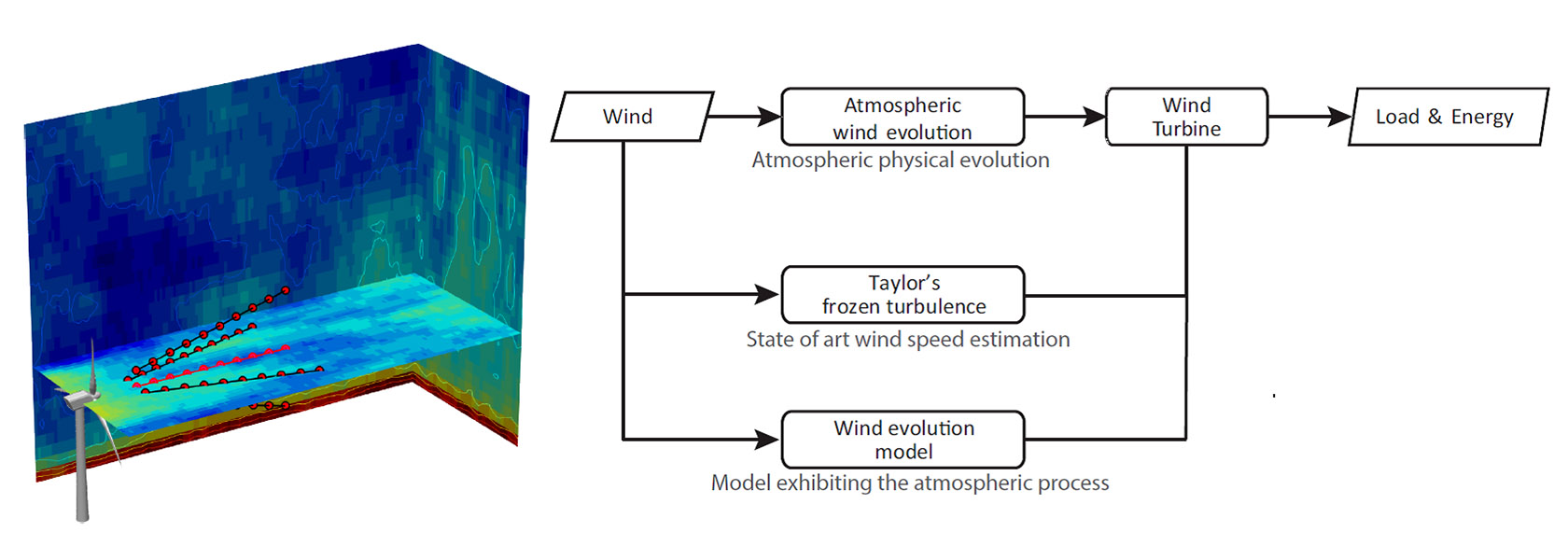

- A model should be made how to derive a wind field at the rotor disc of a wind turbine, to be used as input of real time wind turbine simulations, from the measured wind fields. Up to now it is common in wind energy applications to use the frozen wake assumption: a turbulent wind field moves undisturbed with the mean wind velocity through the rotor plane. This is not correct since turbulent structures will be modified (vortex stretching) near the rotor disc caused by the spatial changes in the velocity field (due to the induced velocities of the wind turbine). This point is relevant for mechanical load testing as well as wind turbine and wind farm control design.

- Power output and load simulations with codes like Focus on basis of the wind field at the rotor disc from point 2. Amongst others the effect of inclusion of wind shear on the energy yield as well as mechanical loads should be investigated.

Further reading