Freeform Manufacturing

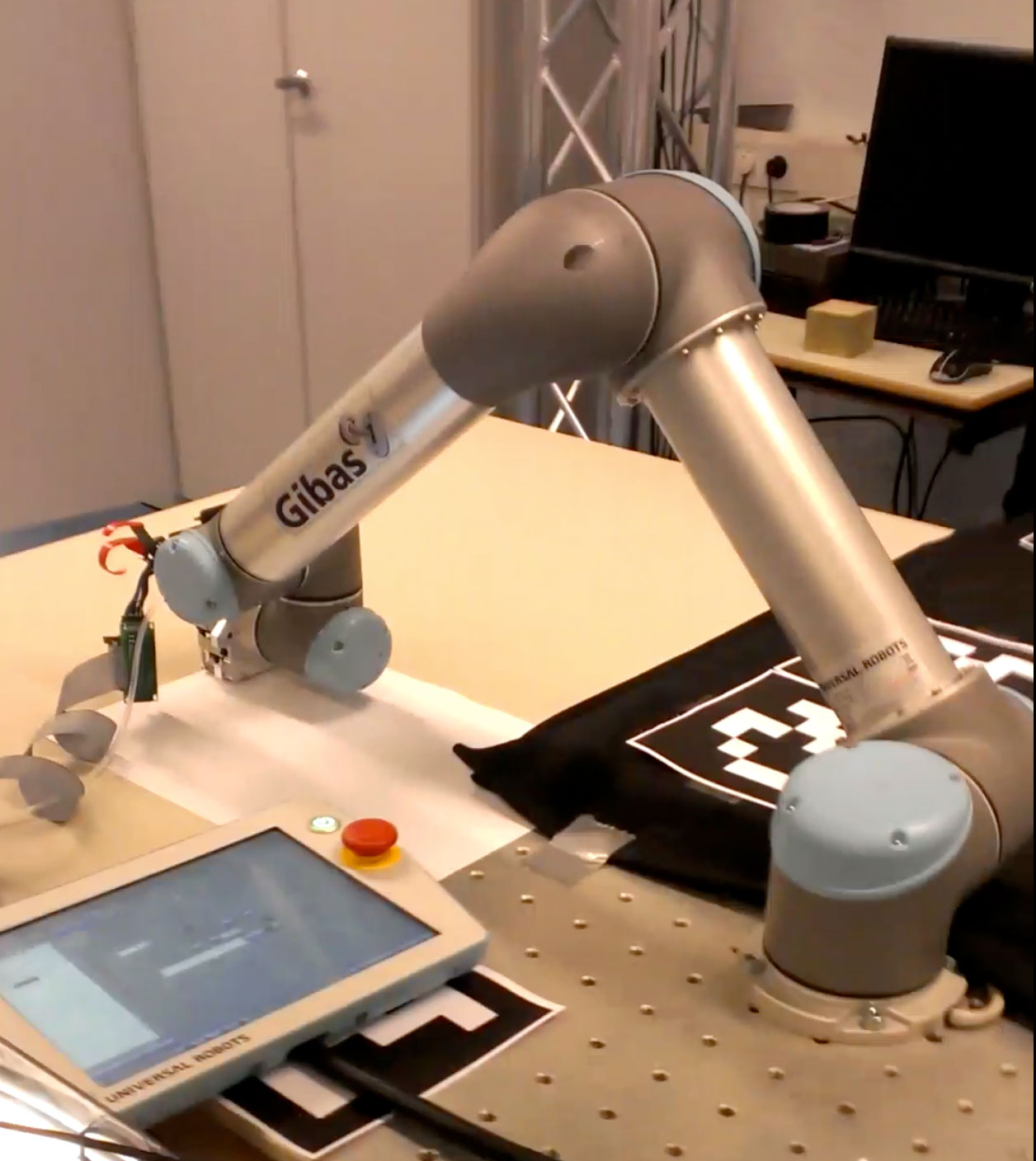

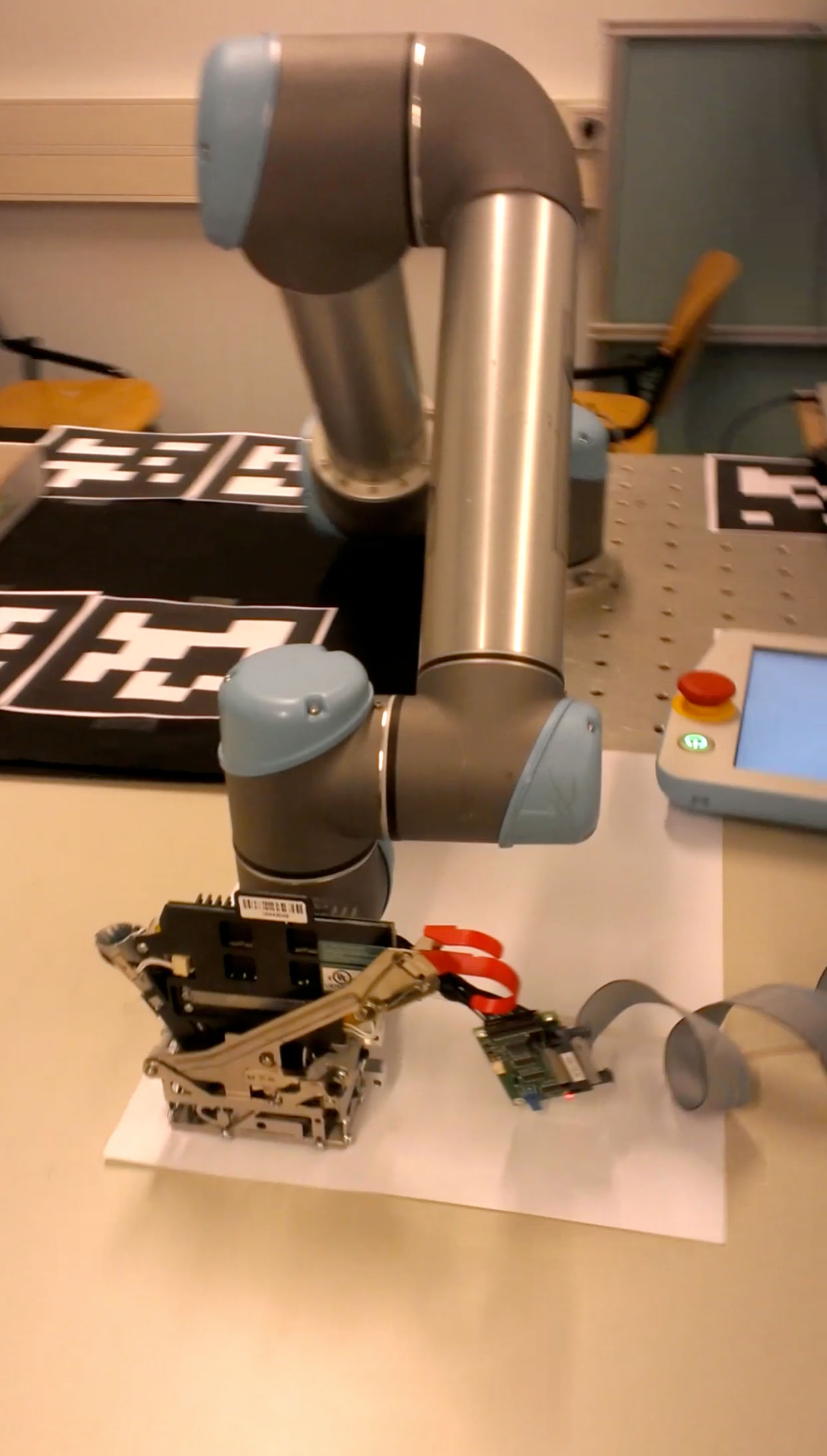

In this project we use a robotic arm and an off-the-shelf printhead. The key challenge is to generate an adaptive printing strategy, depending on:

- real-time scanned surface

- intended material composition

- printhead resolution/width

- robot speed/control

Initial print runs on non-planar surfaces are promising – we reach a high resolution in single-curved surfaces in real time.

Goals of the project

Not everything in the world is flat – how can we deposit material on curved surfaces? In this project we aim to automatically to extend functionality and aesthetics of curved shapes.

2D printing is not just for decoration – with functional inks we can influence reflection/refraction/translucency and electric conduction. This presents new opportunities for designers, from localized on-demand manufacturing to reproducing cultural heritage objects.

Researchers

- Prof. Jo Geraedts

- Robert Babuska (ME)

- Mostafa Hajian

- Jeroen Kruit (graduate student)