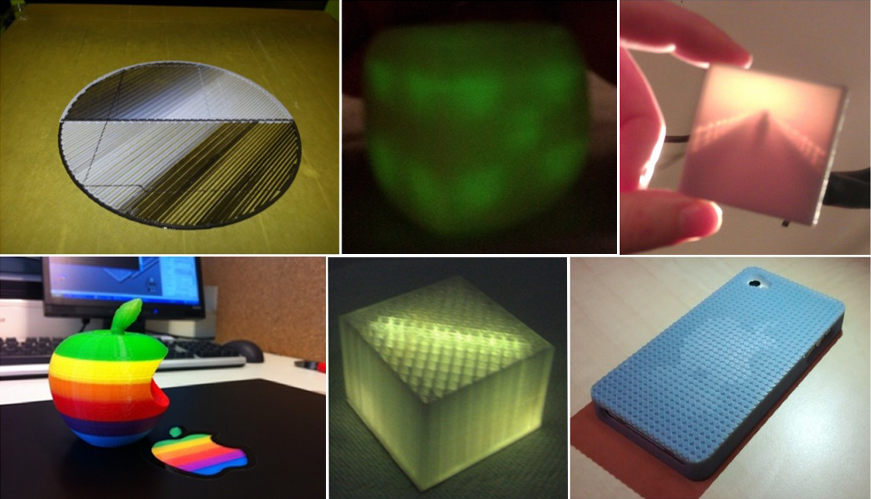

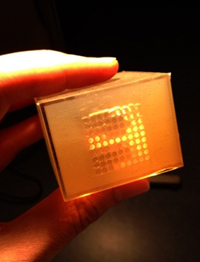

3D Printed Optics and Sensors

Design cases on embedding optics and sensors in 3D printed objects, including prosthetic sockets and alarm clocks. The prosthetic sockets project is pursued in collaboration with the Mediated Matter group of MIT Media Lab and our minor ‘Advanced Prototyping’ programme.

Goals of the project

Enabled by multi-material Additive Manufacturing (3D printing), we are exploring the design and digital fabrication of geometries and material compositions of objects with spatial and temporal variations in properties. This novel paradigm allows control over various properties, such as optical, mechanical, compliant and acoustical within geometry, printed at once. The embedding of (printed) sensors and actuators enables instant human interaction.

However, local control over geometry and material composition presented in our approach cannot be achieved using traditional CAD tools and conventional Additive Manufacturing workflows. This implies that, in order to harvest the current and future capabilities of Additive Manufacturing, new tools must be developed that will allow the design and digital fabrication of objects with desired properties.

More information

Research

- Prof. Jo Geraedts

- Zjenja Doubrovski

- Steve van Bennekom (graduate student)

- Jouke Verlinden

Partners

- Prof. Neri Oxman (MIT Media Lab/Mediated Matter)