Recyling 3D prints

Recyling 3D prints for prototyping

Recycling 3D prints: Enabling material reuse in prototyping facilities

In Fused Deposition Modeling (FDM) for rapid‑prototyping, the 3D printed parts usually have a short life, generating a constant stream of waste material and lost value. This issue becomes more relevant when FDM is used during the early stages of product development, where 3D printed prototypes become rapidly obsolete due to design iterations and advances in the project.

Amongst the materials used, Polylactic Acid (PLA) is one of the most popular in FDM, especially in early prototyping. As a result, prototyping facilities generate a constant waste stream of PLA from failed prints, support material and obsolete prints. A material stream that is not being reused, recycled or composted, as current recycling facilities are not capable of recycling or industrially biodegrade PLA.

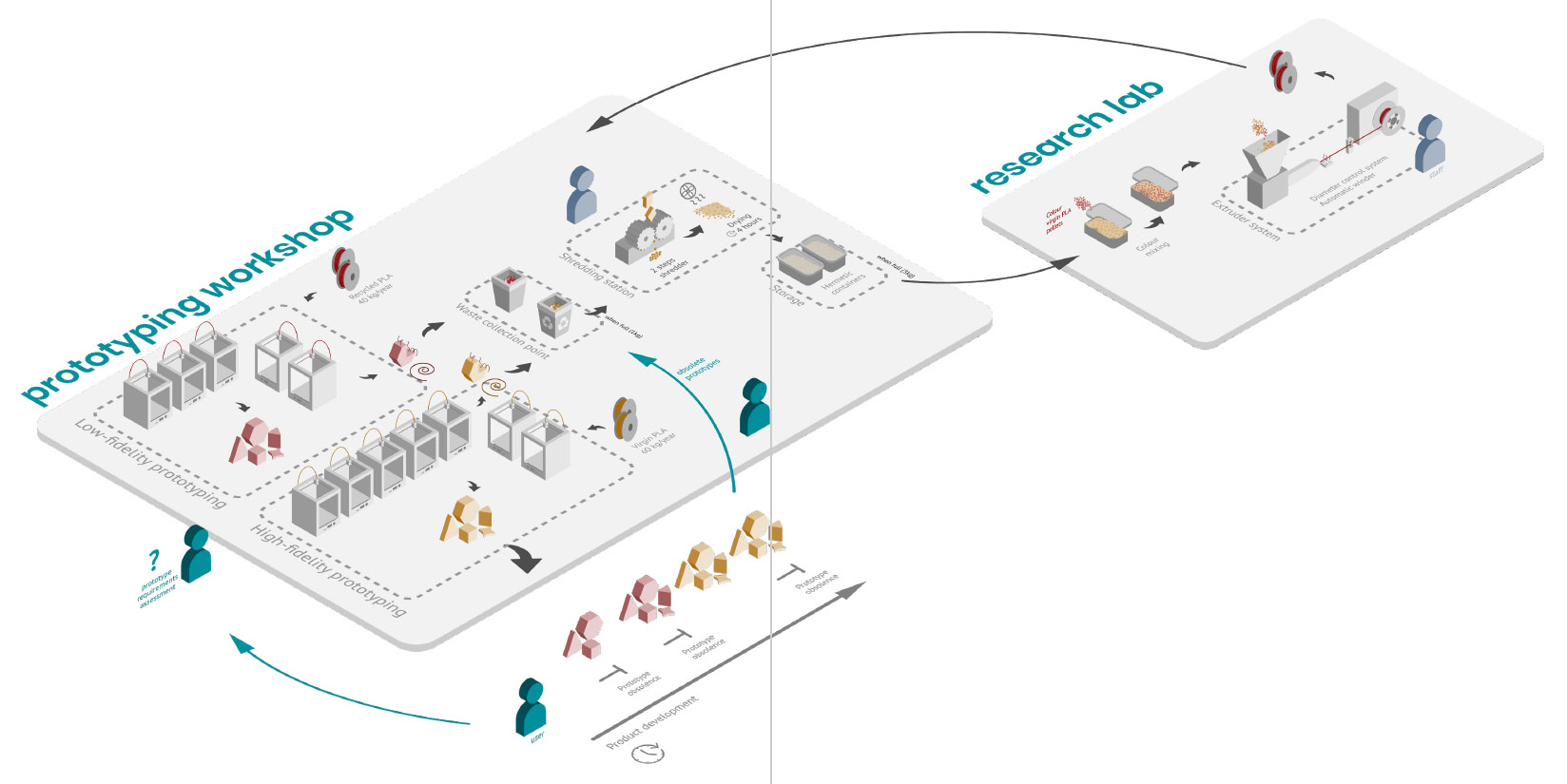

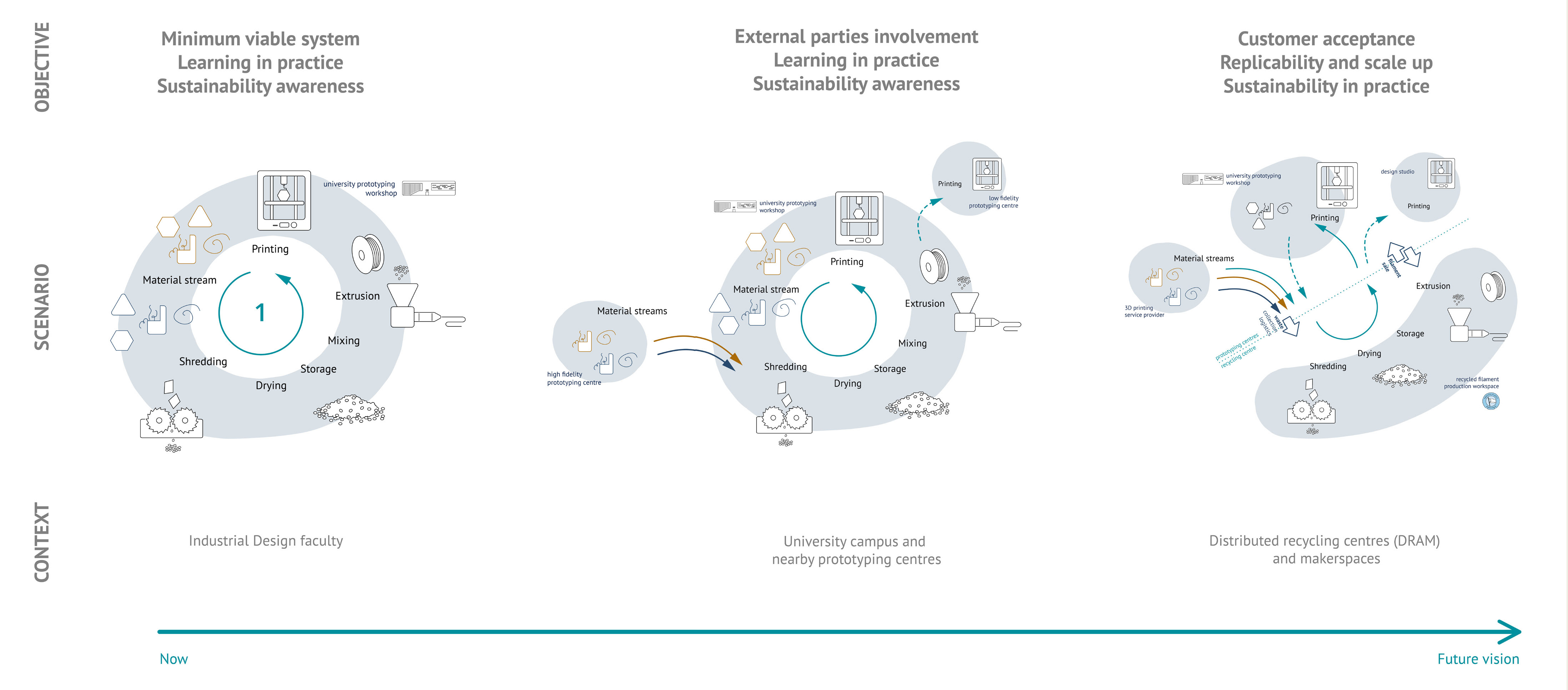

This project investigates the opportunity of reusing this constant waste stream by recycling it back to FDM filament, closing the material loop in a prototyping facility context. Recycling PLA comes with challenges such as material degradation, printability and the influence on the prototyping process.

Recycling PLA for FDM

The different purposes in product development require different prototype characteristics depending on their purpose and stage of the development. In FDM prototyping, the printing settings influence the prototype characteristics and, therefore, some printing profiles are better for high-fidelity prototypes (where higher strength and better surface quality is needed) while others are better for low-fidelity prototypes (where a faster printing speed might be more important than the strength or surface quality). It is in these low-fidelity prototypes where there is a higher potential for recycled material, a material that could have less strength and lower printing quality than its virgin counterpart.

Characteristics

The results show that in order to achieve the mechanical strength of virgin PLA in low-quality prototyping, an optimized printing profile should be used. However, special attention should be given to the brittleness of the material, especially in flexural stress which should be considered during prototype design. Despite the encountered issues, recycling 3D printing material for low-fidelity prototyping is possible.

Recycling system

In order to maximize the impact of recycling FDM materials, a material reuse system between high and low fidelity prototyping centres on a local scale is required, which also allows for more material loops and can be applied for other FDM materials.

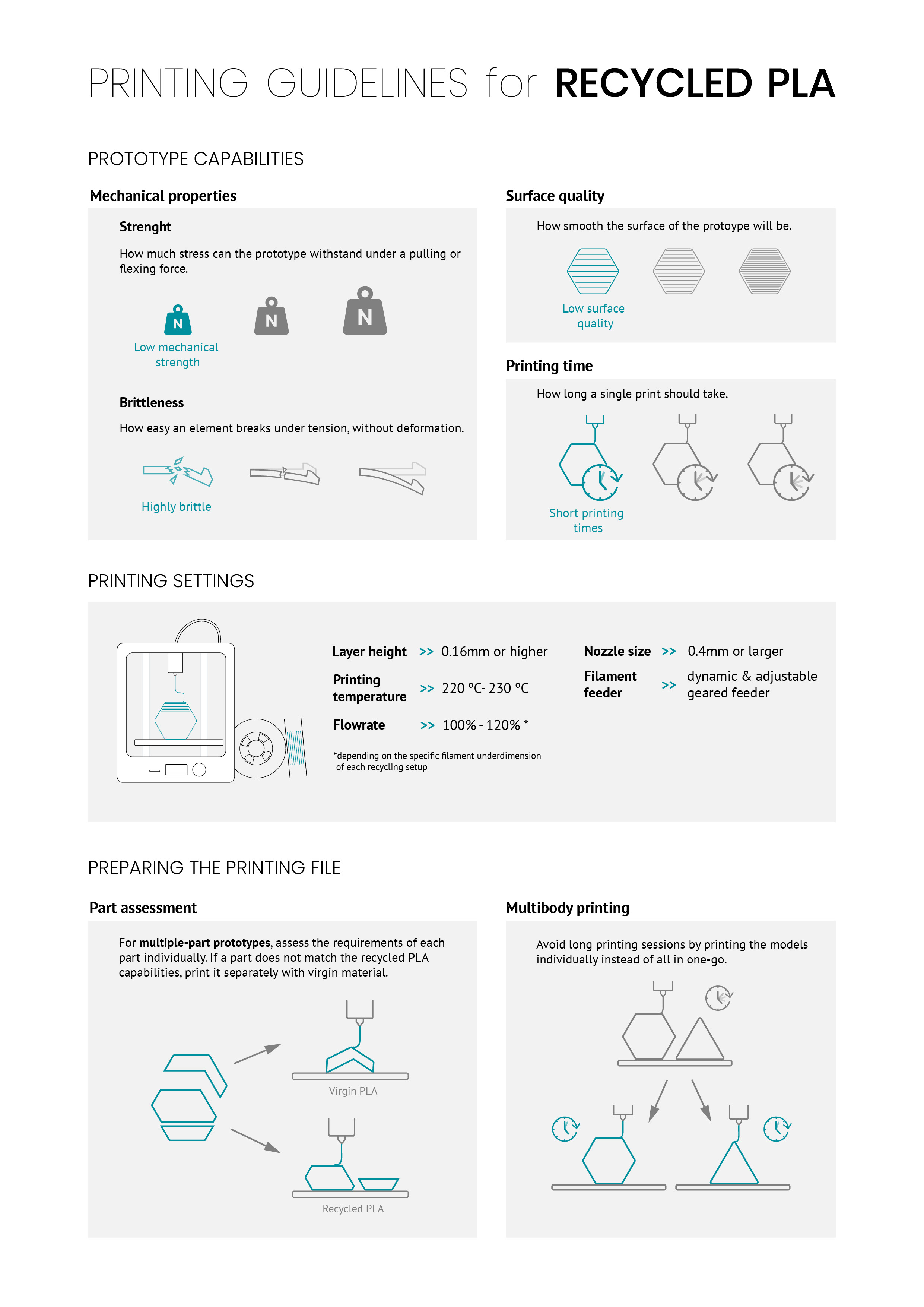

Printing guidelines for recycled PLA

Mechanical Strength

The higher probability of under-extrusion might originate lower layer adhesion locally. This lower layer adhesion can affect the overall mechanical strength of prototypes. Therefore, lower mechanical strength is expected.

Brittleness

Prints of recycled PLA are more brittle than their virgin counterparts. Special attention is needed for those elements where plasticity is desired.

Surface quality

Similarly to the mechanical strength, the higher probability of under-extrusion can cause an uneven surface, with an overall low surface quality of the printed model.

Printing time

Due to a higher probability of nozzle clogging when printing recycled PLA, prints might fail more frequently. Avoiding large parts with long printing sessions can reduce the number of parts that have to be printed again if issues appear before printing is finished.

Preparing the printing file

When printing with recycled PLA, an additional step is needed to assess if the requirements of all parts are fulfilled according to the prototype capabilities of recycled PLA. If it is not the case, the elements with higher requirements must be printed ith virgin material, since lowering the layer height will not result in better prototype capabilities. In addition, when more than one model has to be printed, it is recommended to split the printing file in multiple printing sessions to reduce the printing time, for the reasons mentioned above.

Printing settings

When printing with recycled PLA, a higher temperature and flowrate is recommended to reduce the under-extrusion issues. Since the benefits of using a low layer height, namely better surface quality and higher strength, would be hindered by the issues mentioned above, there is no reason to print with a lower layer height. Large printing nozzles are recommended to reduce nozzle clogging. A dynamic and adjustable geared feeder can reduce the filament grinding and work better with filaments with irregular thickness.

Sander Minnoye

Education director

Graduate:

Marc Aliana Guardia (2021)