MTS 810

MTS 810

The MTS 810 system is a completely integrated testing package to let you easily obtain information about the mechanical properties of your materials or components. With the wide range of load unit, test control, and test accessory options, it is easily configured to meet your exact testing needs.

R&D has two types of the MTS 810 testing packages. A console which can apply a force up to 100 kN and a rapid one with the ability to apply a force up to 15 kN.

Applications

- Fatigue life studies

- Crack propagation and fracture mechanics studies

- Tensile, compression and bend testing

- Asphalt, soil, and geomechanics testing

- Testing in extreme environments.

- Component testing

Controler

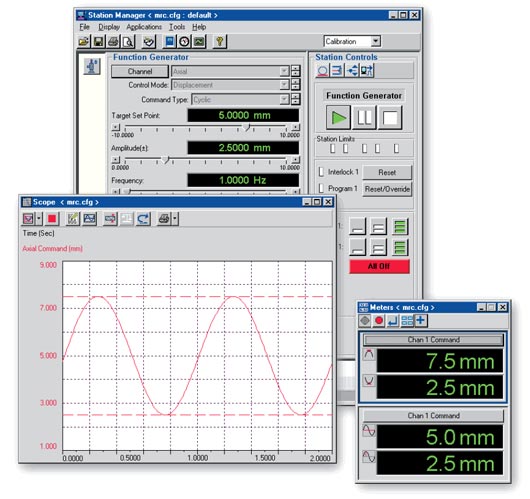

The system’s controller features an intuitive, graphical interface that makes it easy to set up and run your tests without learning mysterious codes or memorizing the functions of dozens of knobs and buttons on a control panel. As a result, you spend less time setting up tests and more time running tests.

Example:

Accuracy

- Superior axial and lateral stiffness

- Accurate load unit alignment

- Low hysteresis and long-term stability

- Precise actuator position measurement

Performance

The lightweight crosshead and stiff load frame components reduce load frame deflections and increase the performance envelope of the system.

Servo valves offer high response and accurate control.

Hydraulic service manifolds with close-coupled accumulators improve the response of the actuator

Load unit stiffness and extremely low friction actuators ensure high possible test control and resolution, making these systems suitable for both dynamic and monotonic testing applications.

Flexibility

- Hydraulic lifts and locks allow the crosshead to be easily positioned.

- Configure the unit to suit your needs by selecting actuator stroke length, force capacity, servo valve, and hydraulic performance combinations.

- All MTS load units are fully fatigue rated.

- Accurate monotonic tests can be performed on the same load unit used for dynamic test applications.

Specifications

- Maximum force 15 kN and 100 kN

- Type Hydraulic

- Maximum testing range 150 mm

- Standards DIN and ISO

Cases