Facilities

The Center of Design for Advanced Manufacturing offers the latest technology in digitalization, digital manufacturing, human robot co-production and computational design. The facilities support in technologies used in research and development of product design for the industry 4.0. On this webpage an overview of the facilities available at the CDAM can be found.

Contact CDAM-IDE@tudelft.nl for more information on the use of the facilities.

Digitalization

The role of digital twin technology is important in enabling agile manufacturing. Part of the digital twin technology is the ability to create digital models from physical models. Transitioning from analogue to digital and using that information enhance the design or the design process is digitalization. In collaboration with the Bodylab we have digitalization technology for both physical objects and the human body.

Contact CDAM-IDE@tudelft.nl for more information on the use of the facilities.

Digital fabrication

The CDAM facilities offer a wide range of digital fabrication possibilities, 3D printing (Plastics, rubber, carbon fibre, conductive material), multi axis CNC milling (Foam and metals), waterjet and laser cutting (Unlimited materials) and automated knitting. The facilities are used in a wide variety of projects for prototyping and support in research.

Contact CDAM-IDE@tudelft.nl for more information on the use of the facilities.

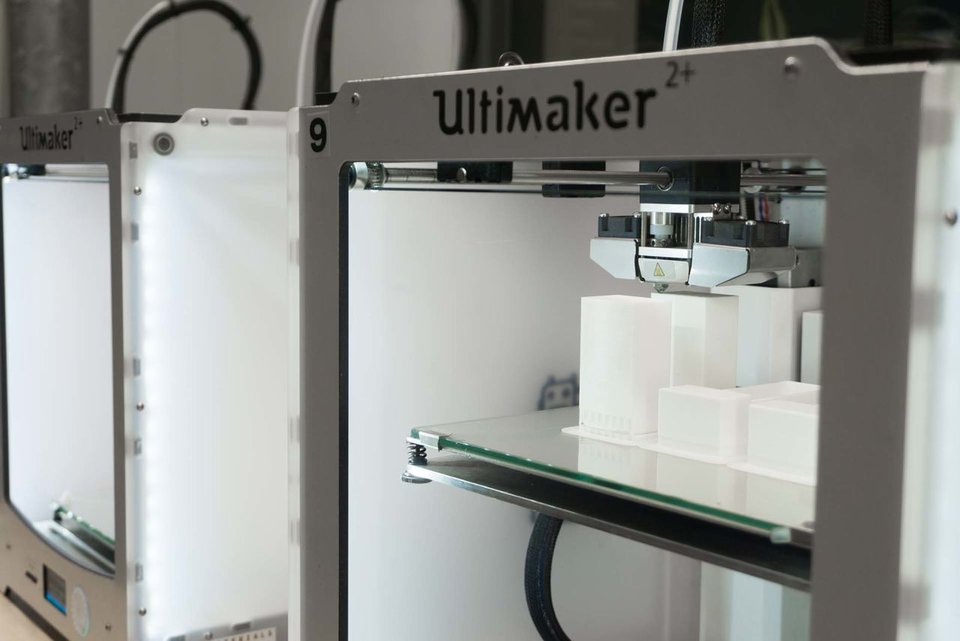

Ultimaker

There are several Ultimakers at CDAM including the Ultimaker S5 which has an enlarged print size and dual print capabilities.Print Area (Ultimaker 3): 215 x 215 x 200 mm

Print Area (Ultimaker s5): 330 x 240 x 300 mm

Human robot co-production

The human robot co-production facilities include several robots that can be used to create and test robot co-production methods. Improving the manufacturing process by combining the advantage of robotics with the capabilities of humans.

Contact CDAM-IDE@tudelft.nl for more information on the use of the facilities.

Computational Design

Digital manufacturing (e.g. 3D printing) enables the fabrication of complex shapes that are difficult or impossible to produce by conventional production techniques. Manually exploring the large design space unveiled by digital manufacturing becomes inefficient and inadequate. Furthermore, product customization necessitates a design process that is scalable. Computational design facilitates the design process with computational tools and methods, aiming at achieving the best design with less manual operation.

Contact CDAM-IDE@tudelft.nl for more information on the use of the facilities.

Computing

For computing there is a 128 GB RAM workstation able to handle demanding work tasks like topology optimizationRAM: 128 GB