Circular composites - design is the missing link

Composite materials have a lot to offer in terms of fine-tuning material properties, optimising functionality, and ensuring a long-life span. Despite those advantages, they still leave a lot to be desired when it comes to reuse and recycling. For his PhD, Jelle Joustra explored strategies for making composite materials that support a circular economy, proposing that design is the missing link.

Mixed materials

These days composite materials can be found all around us, commonly used in industries like construction, automotive, and aerospace. They are created by combining two or more dissimilar materials, such as fibres and a polymer like resin, to form a new material that is generally cheaper, lighter, stronger, or more durable when compared with conventional materials. For this reason, composite materials can be optimised for a desired functionality, as you are able to finely tune what the material behaviours will be.

But it is precisely this mixing of materials that makes composites difficult to recycle or reuse. That’s because separating or reprocessing them when their initial function is over poses various challenges, such as material integrity issues. “It’s not really straightforward to reuse them somewhere else because they’re so tightly connected to their initial function,” said Joustra. “This means that the reuse scope or potential?? is usually quite small and also makes the secondary value quite small.” To change the perspective, Joustra proposes that by anticipating these issues in the design stage, opportunities for reuse and recycling of composites will increase.

Complete circular value chain

Much of the research for Joustra’s PhD was embedded in Ecobulk, a Horizon 2020 project that ran from 2017 to 2021. It involved 30 companies, institutes, and organisations across Europe that represented stakeholders in the value chain of typical composite products. He collaborated with the team via interviews and discussions on how to implement circular design measures, which resulted in the redesign and redevelopment of a complete circular value chain.

The circular economy is not just about recycling, explains Joustra. It’s about extending product lifetimes and usability, shared use, and maximising functionality. It’s also about being able to recover materials, remanufacture parts and components while keeping them at a high value level. “Simply putting our current product into a new type of use life is not going to work because not all products are designed to last for a very long time or to be maintained very well, upgraded, refurbished or remanufactured. That’s often because parts aren’t accessible or are joined together in a non-separable way. To achieve the circular economy, product design is a missing link.”

From blade to table

Through the Ecobulk experience, Joustra recognised they hadn’t addressed ways to reuse structural parts of a large composite product. So rather than shredding and recycling, why not reuse, for example, panels and beams of wind turbine blades? Doing research through design case studies, Joustra developed a segmentation procedure for a wind turbine blade model. While preserving the material’s structural value by cutting panels directly from a used wind turbine blade, he was able to use the parts to develop a picnic table. “I wanted to see how suitable the material is for doing this and what can be done in the design of new blades to facilitate this reuse procedure,” said Joustra. “I found a lot of things that can and cannot be done with the material so it was a very valuable case study.”

The table, which can be found at the Industrial Design faculty, was also exhibited at Dutch Design Week in 2019. “I learned that with such a prototype you can really evoke responses from a wider audience and people had a positive and curious attitude towards this,” he said.

Making the research accessible

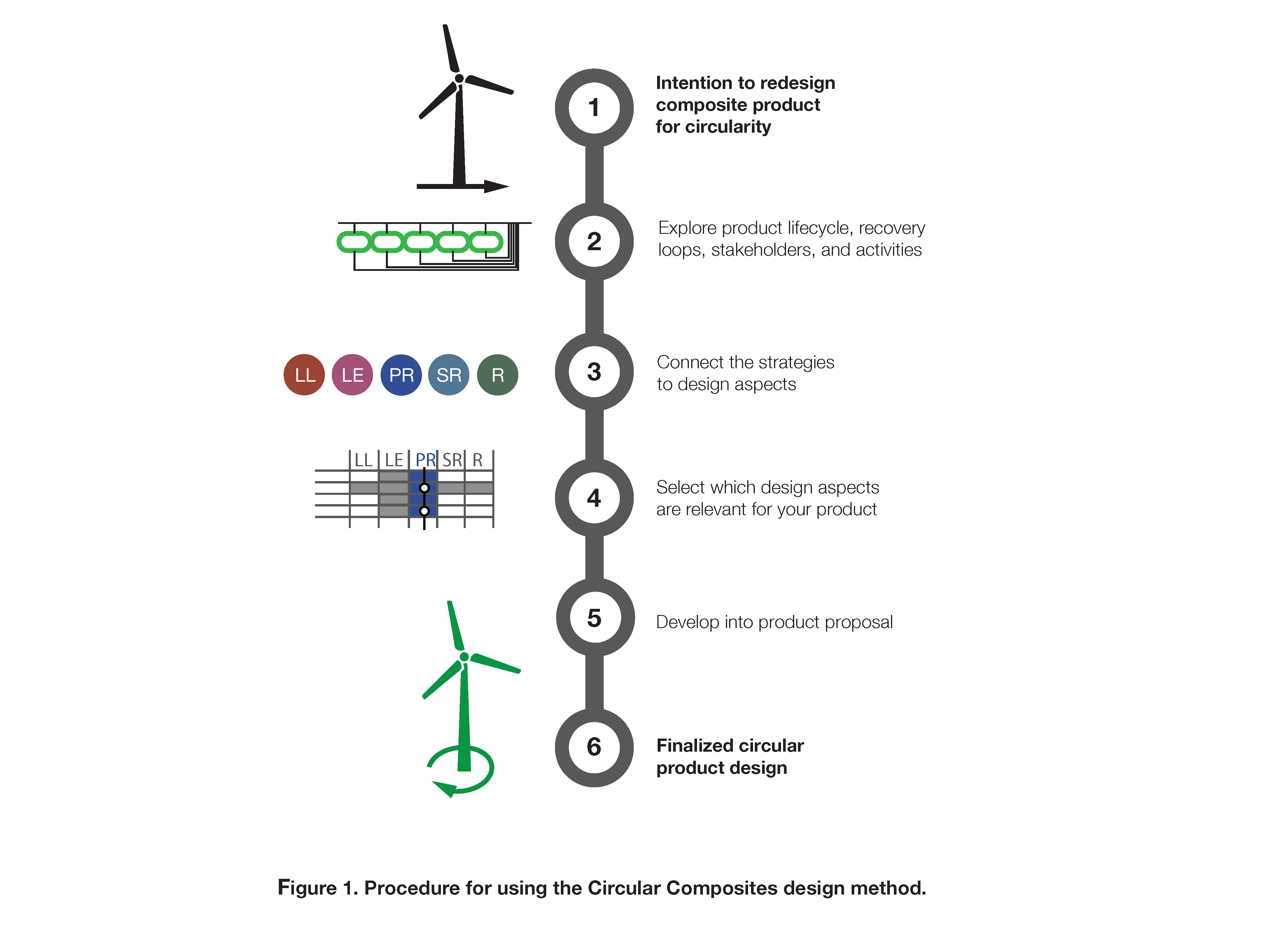

Using his research findings, Joustra and fellow TU Delft PhD candidate Riel Bessai co-authored a book called Circular Composites: A design guide for products containing composite materials in a circular economy. The open access book is a design guide that aims to help integrate circular strategies in the design of composite products. “There are a lot of opportunities for circular design using composite materials. My research and design guide highlight some of these opportunities and ways to achieve them,” said Joustra. “But there’s still more research to be done and more implementation to be done in industry. I’d like to spark that wherever possible.”

Currently working as a postdoc, Joustra will participate in a new research project called LICHEN-BLADES, a collaboration between IDE, TU Delft’s Faculty of Aerospace Engineering, and Maastricht University . The aim is to redesign and develop sustainable wind turbine blades, building on the idea of structural reuse and how to anticipate for secondary use cycles in the design phase.

Design Methodologies

In the wind turbine blade case study, Joustra used material property charts (“Ashby charts”) to evaluate the type of materials that he harvested in order to compare them to conventional materials. These charts plot the strength of the material on the Y axis and the density of the material on the X axis. For designers, this is a way to interpret the type of material and use this knowledge in the design process.

Research through design was also used, where research takes place through prototype development. The product prototype is an object of study, used to evoke responses or test performance. While it may result in interesting spin-offs, taking the design into production is not the main aim of the process.

Joustra also employed circular product design: products being redesigned for reuse and recycling in a circular economy by taking a lifecycle perspective on the design. More about circular product design can be found here.

Jelle Joustra

- +31 (0)15 27 89048

- j.j.joustra@tudelft.nl

- Personal website

-

Room 32-B-3-290

Present on: Mon-Tue-Wed-Thu-Fri

Ruud Balkenende

- +31 15 27 81658

- a.r.balkenende@tudelft.nl

-

Room B-3-310

Bas Flipsen

- +31 (0)15 27 89398

- s.f.j.flipsen@tudelft.nl

-

Room 32-B-3-090

Present on: Mon-Tue-Thu-Fri

"Leave tracks, no traces."