Advanced Material

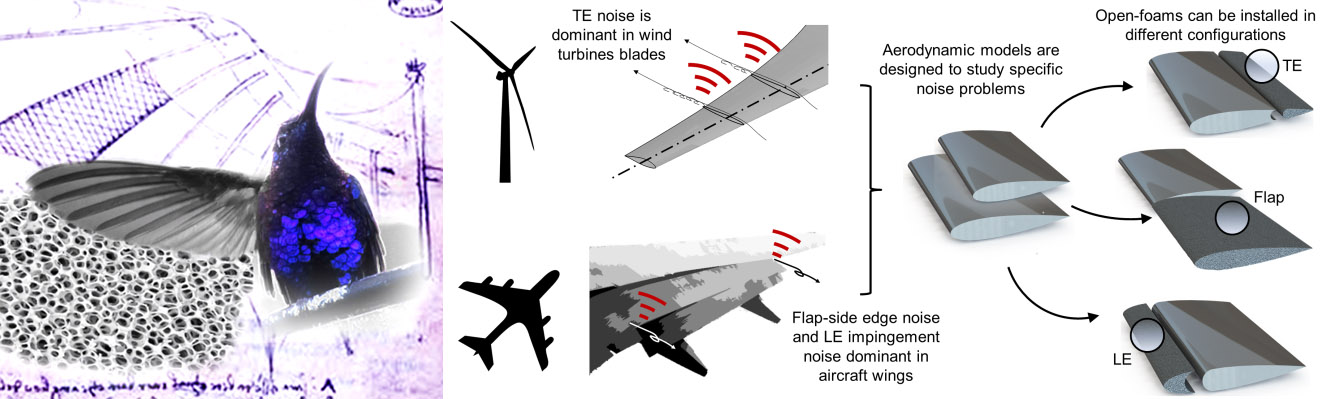

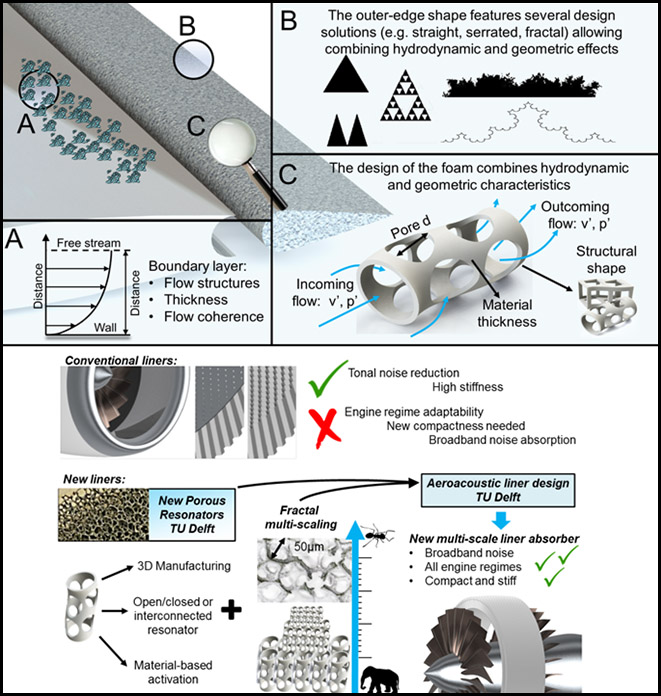

Modern aerodynamics is responding to the world energy‑crisis with the creation of the largest machines on Earth. Among many examples, large wings/blades are optimized to harvest energy from the wind (e.g. wind turbines) or to decrease fuel mass spent per payload (e.g. aircraft and propellers). Improving performance through upscaling comes with a huge increase of aeroacoustic noise, which directly affects the health of human population, as well as it obliges wind‑turbine manufacturers and airports to restrict the operating envelope of wind‑turbines and airplanes. The revolutionary concept, aiming at the abatement of airfoil self‑noise with a new flow‑porous material constituted by “open foams with directional cavities”, allows shaping the macro characteristics (edge geometry, angles) of conventional passive noise‑reduction techniques, into the micro ones of the porous structure (porosity, cavity orientation), towards the creation of a material able to mitigate noise by both dampening flow fluctuations and reducing acoustic scattering. Addressing both hydrodynamic and acoustic aspects of noise is extremely challenging due to the different flow‑scales and physical mechanisms involved. The proposed research aims at studying, designing and prototyping inserts for wind‑tunnel wings with open foams able to work at a multi‑scale level.

Related Master Projects:

- Porous materials for noise reduction

For more information