How can we produce clean and renewable energy in a more affordable way? As we are confronted with climate change and global warming, this question represents one of the greatest challenges of the 21st century. A research team in the field of airborne wind energy of the faculty of Aerospace Engineering recently kicked off their ‘Fast Track to Innovation’ project REACH, which is funded with 3.7 million Euro by the European Horizon 2020 programme. Their ambition? To ensure cost-effective renewable energy with a low environmental footprint by using kite power, or, as it is called more generally, airborne wind energy.

On 31 May 2016, the official kick-off meeting of the REACH project took place at the faculty of Aerospace Engineering. After a word of welcome by coordinator Dr. Roland Schmehl (section Wind Energy), the various partners involved gave short presentations, followed by lunch and discussions. Kitepower, a recent start-up of TU Delft, is at the core of the REACH project with the mission objective to commercialize the technology. Enevate B.V. is the technical coordinator of the project and will integrate the developed kite system, market and sell it. The goal is to have the first commercial prototype of the E100 – the name of the 100 kW kite power system – within two years, and to sell it within three. Several parties have already expressed their interest.

Losing weight and reducing costs

Horizontal axis wind turbines with rigid rotor blades are the most common way of converting wind energy. There are now over 200,000 wind turbines operating worldwide. But these conventional wind turbines have downsides: they are heavy, expensive, make noise and detract from the visual quality of the landscape (and so does the needed infrastructure such as high-voltage lines).

The concept of a kite power system has the upper hand when it comes to these downsides. ‘Wind turbines are very robust. This means they have to deal with immense structural forces,’ Schmehl explains. ‘The tower and rigid rotor blades that take all the aerodynamic loads are heavy and expensive. The essence of airborne wind energy is to replace this heavy structure by lightweight cables and membranes. This way, we might use a tenth of the material – and thus weight – to produce the same amount of energy. This means the cost of energy would turn out dramatically lower if we use kite power.’

How does the system work?

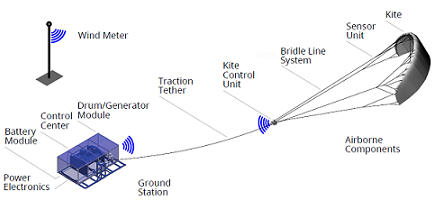

Functional components of the 20 kW technology demonstrator developed at Delft University of Technology

The ground station holds an integrated ground control centre and incorporates the cable drum with a cable routing mechanism. The generator holds a 20 kWh battery. Because it houses also the central control computer, the ground station functions as the ‘brain’ of the system.

The kite control unit (or KCU) determines how the kite flies by steering and depowering of the wing. The KCU is commanded by the ground control centre via several redundant wireless communication channels. Eventually, the goal is to be able to have the KCU function as a ‘brain’ as well, because it would closer to the kite and thus more reliable. Also, it would then be able to communicate with KCUs of neighbouring kite systems to avoid collision.

The kite has 25 m2 surface area and holds an on board sensor platform to continuously measure the position, orientation and velocity of the wing. The wing creates the aerodynamic lift force as turbine blades on conventional wind turbines do.

Challenges ahead

In the coming months, the team is set on showing the feasibility of certain features. One of the first milestones to pass, is flying during the night. This involves illumination, because aircraft need to be able to see the kite. Although every flight is registered, a back-up plan is needed, should communication fail. A second milestone would be to fly for 24 hours straight by the end of this year.

The advantage the kite system has over the wind turbine – its low weight – poses a challenge. The system must be lightweight, but also strong enough to be reliable and durable. One particular difficulty in this is securing automatic launches and landings for the system: ‘If there is a thunderstorm coming, or troubles occur with a wind turbine, you can simply push a button and it will stop rotating. A flying system is very different, as you will need to land it. You cannot just stop mid-air.’

Lastly, there is currently an ongoing debate on whether a kite power system should be considered an aircraft or an obstacle. Certification of the E100 is therefore also something that will be handled in the near future. Schmehl: ‘By the end of 2017, we want to have a commercial prototype of the 100kW system.’

The 20 kW kite power system of TU Delft in operation at the former naval airbase Valkenburg, The Netherlands

- TU Delft: general coordinator, contributes research

- Kitepower: associated start-up, technical coordinator

- Dromec B.V.: ground station

- Maxon Motor GmbH: control drive trains

- Genetrix: kite development and production