When Max Roest started guitar lessons at the age of four, he had no idea that, two decades later, he’d make one for his master’s graduation project at the faculty of Aerospace Engineering.

Roest had long been a guitar player, even producing an album called ToneWood, which was released in 2012. He’s competed nationally in the Netherlands but ultimately, the guitar was a hobby and not a professional pursuit for Roest.

After completing his bachelor’s degree in aerospace engineering at TU Delft and moving on to the master’s programme, Roest was in need of a thesis project. He was inspired by the winner of the 2010 TU Best Graduate Award. Maarten Kamphuis, an Industrial Design Engineering student, who created a training sword for Historical European Martial Arts (HEMA.) Kamphuis was a proficient HEMA longsword practitioner and Roest was attracted to the idea of combining work and his hobby. His first step was to contact Dr. Otto Bergsma, a professor in the Structures and Materials Department, who agreed to serve as Roest’s thesis supervisor.

As acoustic guitar players, like Roest, are aware, while wooden guitars may produce a warmer sound, this comes at a cost. Wood is very sensitive to changes in temperature and humidity. Touring musicians know their acoustic guitars will sustain damages, even when they are being well-cared for. There are guitars made from composite materials available on the market already. But, as Roest describes, “Their sound is brittle and lacks the character of a wooden guitar.”

So, inspired by a sword making IO-graduate, Roest proposed to complete his thesis on developing a composite material which would emulate the sound of a wooden guitar without the downsides of the fickle wooden material.

“Wood is a lot lighter than most composites,” Roest says, “so that was the most difficult criteria to match.” He also needed a material that would match in stiffness and internal damping. He started with a polethylene material but had to abandon it due to issues with bonding. He also tried existing composite materials with foam layered in between but the damping wasn’t high enough. After three months of experimentation, he discovered that fibre-reinforced foam appeared to meet his criteria.

Then, however, he had to design a testing method to verifying the acoustic properties of this new material. Fortunately, he met Farbod Alijani, a professor in ME who just so happened to have a master’s student starting in his group who was designing a similar testing method for another project. “I was very very lucky to meet Luka Marinangeli.”

The two created a production method that resulted in panels which were very, very similar to wood. And not just any wood, moon spruce which is felled according to lunar cycles and is Roest's preferred material for his guitars. Merely producing the material did not prove sufficient for Roest’s own exacting standards. He wanted to building a complete guitar. With an estimated price tag of €10,000, however, Roest first needed to talked to Dr. Rinze Benedictus, Head of the Structural Integrity Group. “He supported me in exchange for also making the faculty a guitar.” Roest did and it now sits in his office in the Faculty of Aerospace Engineering.

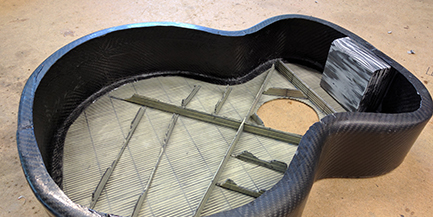

Once they secured funding for the project, Roest approached the technicians in the Delft Aerospace Structures and Materials Lab. “These technicians are underappreciated at the university, I never would have completed the project without their help.“ With their help, he created a guitar form out of a strong plastic and was able to attach the panels.

In the interest of science, Roest tested his new guitar in the anechoic chamber also known as the “dead room” at the Faculty of Applied Sciences. It wasn’t his first trip to the space. He played in the room previously, using his traditional guitar. You can watch a video of that performance on YouTube.

The project was more than just a fun challenge. Much of the high quality wood that is used in guitars is harvested in Alaska, in the United States, where deforestation has reduced the availability of wood. “At the current rates, we might run out of this high quality wood in ten years,” says Roest. While guitar-making is a fairly small portion of overall wood use, finding a viable alternative would be good for the industry.