Project MARCH taking steps in exoskeleton technology

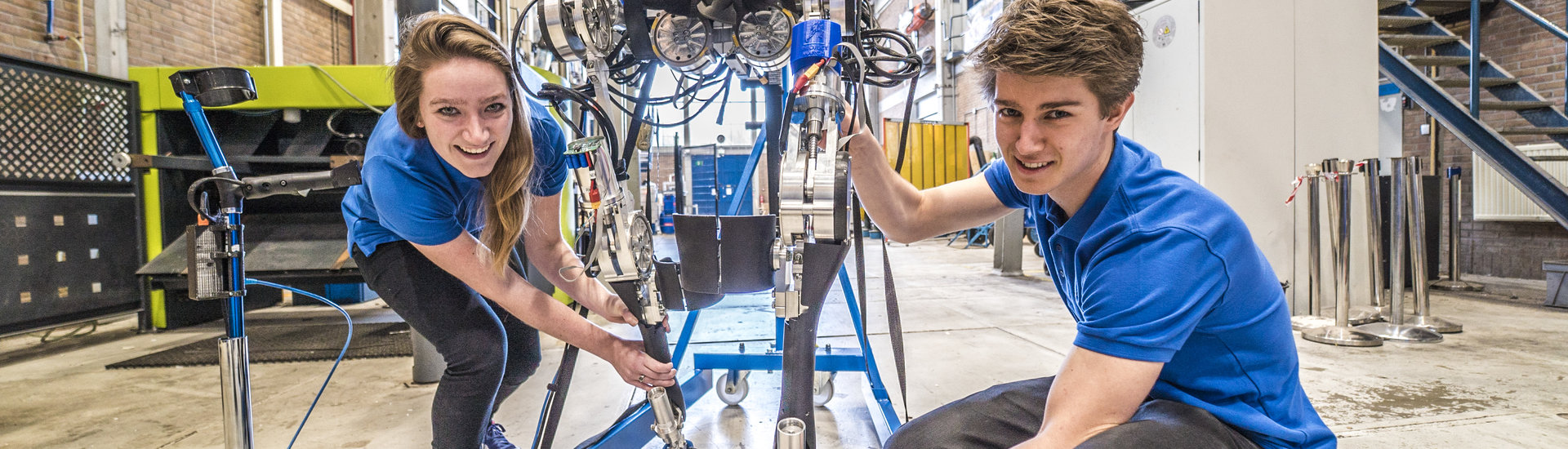

In October 2017, paraplegic Ruben de Sain took less than seven minutes to complete an obstacle course using a special Project MARCH exoskeleton. This is a major triumph for the student project, explain Marise de Baar and Donald Dingemanse. “Overcoming the four obstacles was much more important than coming first,” says De Baar.

Sitting is the new smoking, is something you often hear people say. But people stuck in a wheelchair because they are paraplegic have no choice in the matter. Or that was the case until recently because, in the last couple of years, exoskeletons have become available, external aids that paraplegics can use to stand and walk again. However, they still need some technical improvements and are very expensive because of the lack of competition. “To put it bluntly, it's a very small market and businesses are reluctant to enter it,” says spokesperson Marise de Baar. “But why would you not want to help these people?”

Project MARCH has been doing just that since 2015. That was when a team of 33 students developed the first version of their self-designed exoskeleton, the MARCH I. They intended to use it to participate in the Cybathlon 2016, a kind of bionic paralympics for people who rely on assistive technology to get about. Unfortunately, this first team were not quite ready to complete in the Powered Exoskeleton Race for which they had signed up. But they learnt an amazing amount and the next team of students were able to build on that knowledge.

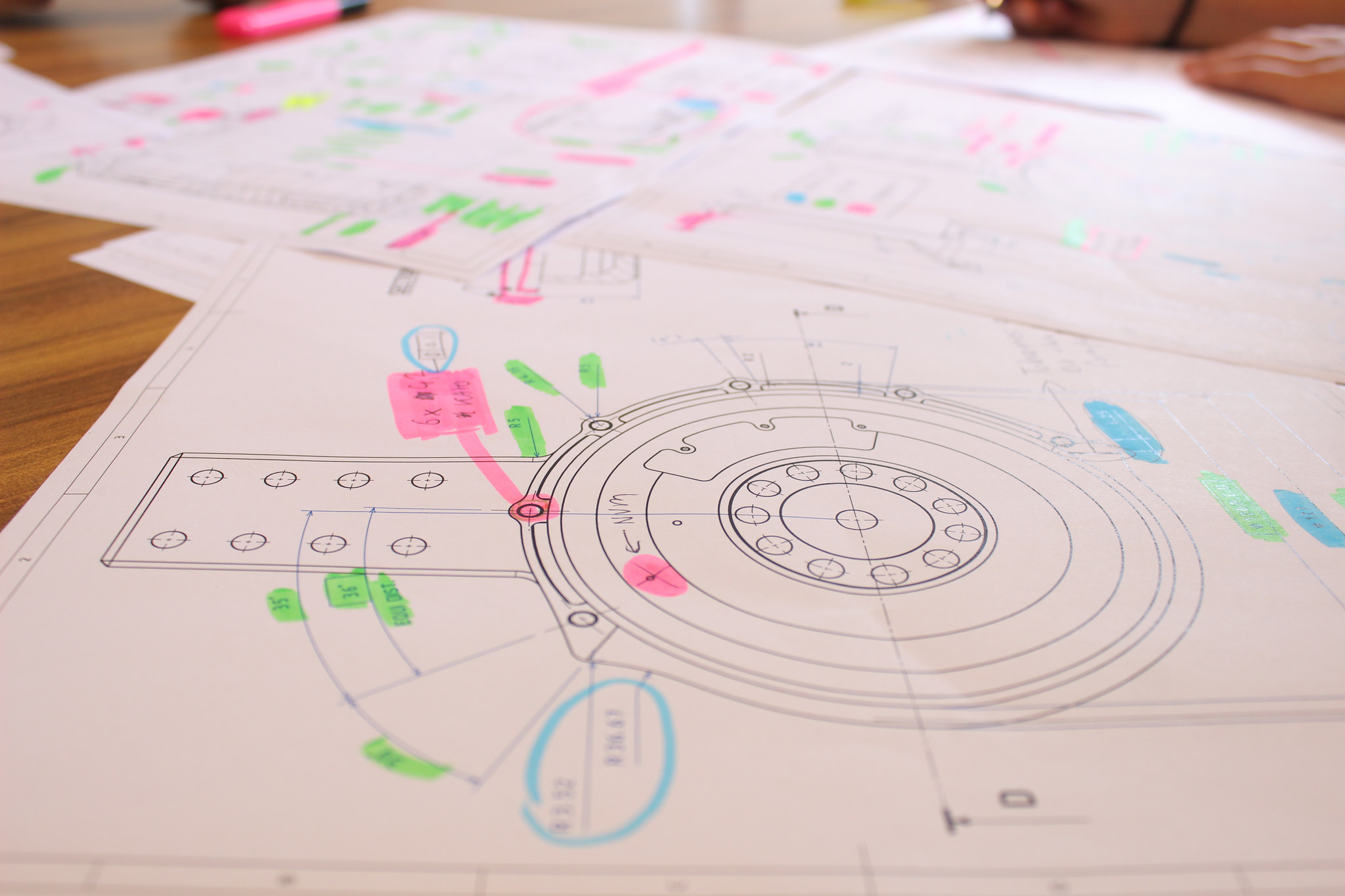

In 2016, the team headed up by Dingemanse and De Baar decided to embark on a completely new design. Although the first version proved in practice to be good for standing up, it was less effective for walking and running. “The problem was to do with the mechanism on the hips and knees, in other words the exoskeleton's joints,” explains team leader Donald Dingemanse. But modifying the joints was not an option. “The joint mechanism actually forms the basis for the whole device, so if you change it, you have to change everything.” This meant changes including the development of new electronics and the writing of new software to control the walking movement.

Cogwheel principle

Technically, the difference primarily comes down to how power is transferred. “Our system of propulsion rotates and works with a type of cogwheel or gear principle, enabling the effective transfer of power from cogwheel to cogwheel,” explains De Baar. “De MARCH I used linear power transmission controlled by an arm outside the joint. It was less powerful and less compact. Our rotating system is in the joint itself.” Dingemanse adds: A problem with linear transmission is that it has less power when you hit a specific angle; our axial rotation system ensures that you always have the same power.”

One thing is certain: an exoskeleton is extremely complicated and made up of all types of subsidiary systems that have to work together effectively. This calls for a multidisciplinary team, which means that the students come from all over the campus. “The most important thing in a group like that is cooperation,“ says Dingemanse. “It means you really need to get to know each other well and ensure that everyone is on the same page.” He admits that it took some time to get used to his role as team leader. “I actually prefer just to agree things within the group, but you occasionally have to make a decision, even if you don't have detailed knowledge about every area.” De Baar agrees: “At the start, I also wanted everyone's opinions about the PR. But the more opinions there are, the more difficult it gets. It takes up too much valuable time and you've just got to get on. It's interesting to see how you grow in the role.”

D:Dreamhal

So lots of finding things out for yourself, but there was also plenty of help available. Some of this came from the other student teams in the D:DreamHall, the homebase for TU Delft’s dream teams that participate in international student competitions. Project MARCH has taken its place there alongside teams that vary from rocket builders to solar car racers. “The atmosphere in the hall is extremely upbeat. There is no competition between the teams, because each one is unique. But at the same time, you can also find that you encounter the same problems. That's when you see how your colleagues resolve the issue,” says Dingemanse. “The first time we started walking with the MARCH II, the place was full of people who wanted to watch. It was great. We also went to watch when a vehicle was completed,“ adds De Baar.

The contact they had with their predecessors was also excellent. “That first group really started from nothing. Not everything went well, but that was also something we could learn from,” says Dingemanse. “They're still extremely enthusiastic and came to cheer us on at the competition in October.” Their contact with the new team is equally good. “We're supporting the third team just as the first team did us,” says De Baar. “We're all working to achieve the same goal, whether that happens this year or in ten years' time. We all want walking with an exoskeleton to become easier and better.”

This drive to help people is something that they both share. “As an engineering student, it's great being able to use your knowledge for a higher purpose, such as giving people some quality of life,” says De Baar, who is now doing a Master's programme in Chemical Engineering after completing her Bachelor's in Molecular Science & Technology. “When I start my career, I would like to do something in that area. In my specialist field, I'm really interested in the pharmaceutical side. I want to specialise in developing drugs to cure diseases that are currently incurable.” Dingemanse could not decide between studying medicine or industrial design engineering. After a minor in medicine for engineering students, he ended up becoming involved in Project MARCH. “It's really special being able, while still a student, to contribute to a technology that's not yet good enough.”

Currently, an exoskeleton is not a good enough alternative for a wheelchair. “A wheelchair still has the edge in terms of speed. Walking in an exoskeleton is also very tiring and you cannot keep it up all day long,” says Dingemanse. But using an exoskeleton helps avoid all kinds of health problems that are associated with long-term wheelchair use. “Your circulation improves and you don't have pressure sores or gastrointestinal issues anymore,” says De Baar. But for users, that is not the main advantage. “For them, the social aspect is much more important: being able to look people in the face again and not being the only one always sitting down.”

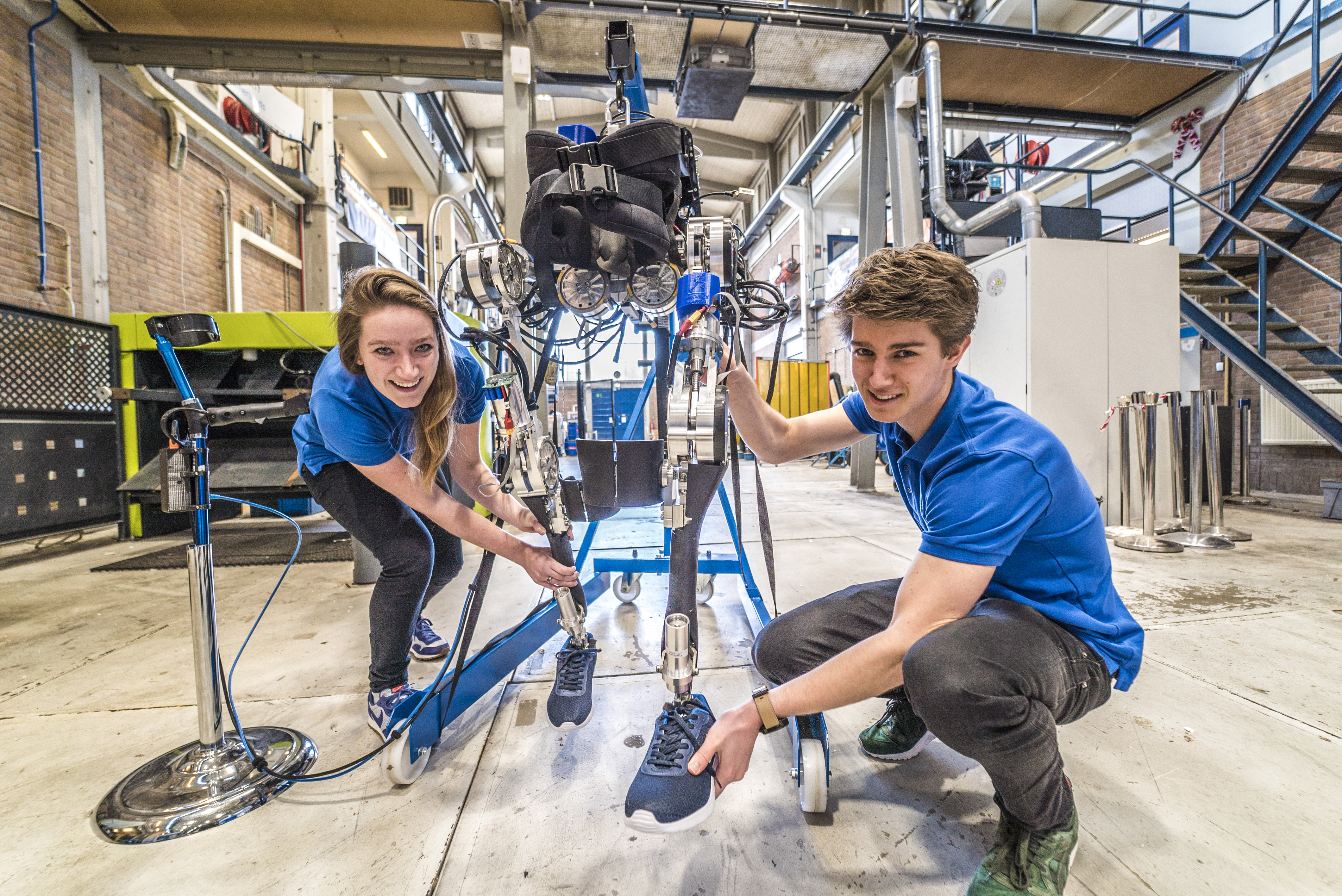

In order to develop a better system, you need someone to walk with it. That was Ruben de Sain, the project's pilot. “We use the term pilot to indicate that the person walking in it controls the exoskeleton and not the other way around,” says Dingemanse. De Sain is an exception among paraplegics, because he funded his own exoskeleton, a commercial ReWalk, via crowdfunding. “He's one of the lucky ones because they cost € 85,000. That's another reason for trying to introduce more competition into the market, in order to reduce the price,” says De Baar.

De Sain was the only team member who is not a student, but his personal experience proved to be extremely important. De Baar: “The difference in the steering was something he noticed immediately. His device is controlled using a watch, but you also have to hold your crutches, which is very awkward. That's why we integrated control into one of the crutches so you can operate it while walking. He found that to be a real advantage.” The MARCH II also makes less noise and is more powerful. Dingemans: “This means you don't have to apply so much effort with your arms when standing up or walking upstairs. Ruben really liked that.” The control in the crutches also makes stopping much easier. With the ReWalk, you have to make a particular movement to stop and it is difficult to learn.

With all these advantages, how did things turn out in the competition? The Cybathlon 2017 was held at REHACARE, a rehabilitation trade show in Düsseldorf. “We spent a whole year building up to it,” explains Dingemanse. The competition took place on a course with obstacles such as a door, a staircase, beams, rough undergrowth, and began with a soft sofa that the competitors had to get up from. “Over four days, you were allowed to make several attempts at getting past all the obstacles, but you had to do it in eight minutes for it to count in the competition. The first time, Ruben took 13 minutes to do it.”

So there was work to be done. In the days that followed, there was a lot of practising. It then emerged that the students had a big advantage over the rest of the competition: flexibility. “A commercial company uses the models that are on the market. They don't do any last-minute soldering work during the competition,” says De Baar. “On day three, we realised that Ruben was losing a lot of time on the staircase.” In order to grab the banister, he had to switch the control crutch into his other hand. “That night in the hostel, we put a control into the left handle. Mind you, the change had to be re-approved by the competition supervisors.”

It proved to be the key to success. Eventually, De Sain was able to complete the entire course in 6.55 minutes. “Ruben was extremely satisfied, although his muscles ached a lot,” says De Baar. “Everyone was really happy for us. Even the moderator was moved.” This performance put Project MARCH second in the competition, behind a team of PhD students from the Technical University of Lausanne. The commercial ReWalk came third. “We're the first student team to make real progress with exoskeleton technology. We're even better than the commercial company,” concludes Dingemanse with satisfaction. “But our competitors are also our colleagues. We share knowledge to continue to improve the technology.”

Personal development

It is now back to the reality of studying, which especially De Baar is finding quite hard. “After spending a year as a full-time PR manager, I've realised that I really enjoy putting the story across.” This is why she is continuing for the time being as PR-manager for the D:Dreamhall alongside her studies. Dingemanse will soon be starting his Master's in Integrated Product Design, specialising in Medisign: industrial design engineering for the medical world. “I've discovered that I find the medical aspect very important.”

Both of them feel that they have really benefited from Project MARCH. Dingemans: “For example, you learn to work with groups: what can you expect of other people and what do you need to sort out yourself? You also need to visit companies to find sponsors. It's certainly rather different than organising a party.” De Baar agrees: “I've also been a member of party committees and you simply do what your predecessors did. This was above all a year of firsts. But then I thought of Pippi Longstocking who said ‘I've never done it, so I rather think I can.’ I've achieved more in terms of personal development this year than in my whole Bachelor's programme.“

Personal information:

Name: Marise de Baar

Country: the Netherlands

BSc: Molecular Science & Technology

MSc: Chemical Engineering

Name: Donald Dingemanse

Country: the Netherlands

BSc: Industrial Design Engineering, TU Delft

MSc: Integrated Product Design