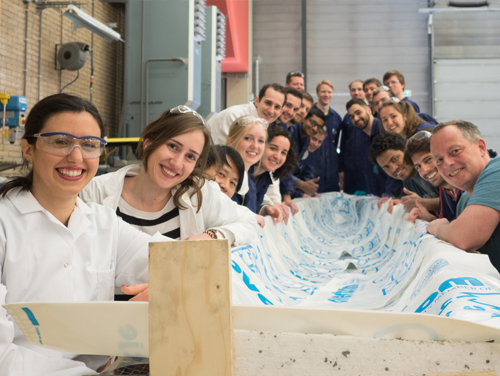

A drum roll sounds in the Stevin II laboratory. 20 students and researchers in blue lab coats and safety shoes are gathered around a 6 meter long canoe mould. They have 15 minutes to properly distribute the mixture in the mould, tamp it down and do the finishing. ‘Faster!’ shouts researcher Marija Nedeljković and the rhythm of the patting hands accelerates. Then Arthur, the leader of the student team, comes with a large plastic sheet to cover the mould. The first cement free concrete canoe has been finished.

This canoe is special for researchers Marija Nedeljković, Mladena Luković and Ye Guang, as well as for the U-base fraternity’s students. After a few years absence, the frat can again take part in the much-loved concrete canoe race in Arnhem in late May. This race will be more special than usual as their concrete canoe contains 0% cement. So, how does that work?

Geopolymer concrete

The canoe is made of geopolymer concrete, also known as cement free concrete. This relatively new material with concrete-like properties uses only industrial by-products as binder instead of the traditional Ordinary Portland Cement (OPC). This makes geopolymer concrete a sustainable alternative to traditional concrete. Marija Nedeljković, a PhD researcher working at the Microlab of TU Delft, explains. ‘Manufacturing OPC involves heating limestone in a kiln to form minerals which are grinded afterwards. These processes consume both energy and natural resources on a massive scale. The total CO2 footprint per one ton of Portland cement is almost 1:1, meaning that for each ton of Portland cement produced, one ton of CO2 is emitted.

In geopolymer concrete, on the other hand, OPC binder is replaced with a mixture of alkaline and industrial by-products such as fly ash or blast furnace slag, which are produced during the manufacturing of, for instance, steel. Therefore, geopolymer concrete preserves natural resources, produces less CO2 and allows us to use by-products to develop a sustainable construction material and to reduce our carbon footprint.’

From tiles to structures

Geopolymer concrete insulates and deals with heat better than traditional concrete. It is already used to manufacture fire-resistant tiles or walls. However, the TU Delft researchers want to go further. Imagine how beneficial it would be if this sustainable concrete was actually used in the construction sector? ‘Concrete is the most utilised construction material on the planet and is allegedly responsible for 5% to 8% of all CO2 emissions,’ explains Ye Guang, associate professor at the Microlab. ‘If geopolymer were used worldwide that would be great for the environment.’ Still, a lot has to be done!

‘So far we have mostly focused on using geopolymer concrete in non-structural applications,’ explains researcher Mladena Luković. ‘This canoe is our first attempt at manufacturing a real structure. To ensure that it can carry loads and stay waterproof we have added fibres to the concrete mix. It worked out great and the students stayed dry during their first trial ride. The canoe is strong enough to race with!’

Guidelines for the construction industry

However, the biggest issue is that there are no standards for application of geopolymer concrete and no rules or guidelines for structures made from it. Ye Guang and his Geopolymer research group from the Microlab are therefore now working on a number of mixtures and are studying the durability and time-dependent behaviour of geopolymer concrete. Mladena from the Concrete Structures group is meanwhile looking for ways to use geopolymers in structural applications. This will allow the team to provide recommendations to industry partners so homes can finally be built from geopolymer concrete.

Or boats, of course. Concrete canoe race, here we come!

During the Concrete Canoe Race of 2016, the U-base team has won two awards. Their concrete canoe weighed 250 kilos and was therefore the heaviest canoe of this year’s race. Most importantly, the team was given the award for most sustainable canoe because of the extraordinary material the canoe was made of.