With palm oil being the most widely used vegetable oil in the world, the industry is likely to stay with us for the foreseeable future, despite its controversial reputation of pollution, deforestation and ignoring the needs of local communities. “The palm oil industry is only expanding, so doing nothing is not going to solve the problem,” says Dr Ralph Lindeboom of the department of Sanitary Engineering. Together with the PhD-researcher and Delft Global Fellow Saqr Al-Muraisy , he aims to help make the industry more sustainable for both the environment and local people

With plantations covering hundreds of thousands of hectares, the palm oil industry is widespread in South-East Asia and Africa. In addition to creating jobs and income from exports, it also generates enormous amounts of organic waste. This is often either burnt or left on the land, with considerable greenhouse gas emissions (like methane) and its related climate impact as a result. Then there is the mill effluent, which pollutes local soil and water, adding to the methane emission in turn. However, in recent years, multinationals like Dutch food giant Unilever have been urging the industry to clean up its act. “Big firms are increasingly threatening to boycott palm oil producers that are not managed sustainably”, says Lindeboom.

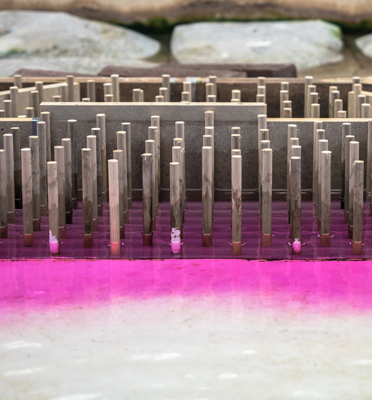

Empty fruit bunches

As an expert in the closing of nutrient cycles, Lindeboom focusses on the empty fruit bunches that are the main source of organic waste during palm oil production. “These fruit bunches are roughly the size of a banana bunch, but as the fruits are much smaller, half of that is organic waste. Part of it is usually burnt to make steam for the sterilisation of the fruits, but still some 80% remains.” These empty fruit bunches could be an excellent source of biogas. “It would need some kind of pre-treatment to break down the lignocellulose before the biogas producing microorganisms could do their work”, Lindeboom explains. Al-Muraisy is looking at natural resources such as concentrated solar power (CSP) to break down the chemical bonds for that . Or you could use fungi that produce enzymes such as laccase and peroxidase, depending on local circumstances. ” “Concentrated Solar Power, which is abundant in Malaysia and is high in total solar irradiance, is a novel technology in the palm oil industry. The main scientific challenge lies in utilising this environmental friendly technology in a way that makes it suitable for this specific type of waste.”

Companies in Malaysia, the second-largest palm oil producing country after Indonesia, are already taking steps towards sustainable production. For example, one of the main agenda points under the National Key Economic Area (NKEA) is to achieve the installation of biogas facilities in all palm oil mills in Malaysia by 2020. Lindeboom’s and Al-Muraisy’s project co-partner, Dr Shahrul Ismail from the Terengganu University, Malaysia, is looking for strategies to fulfil this target. One of his findings is that the biogas production at the mills is insufficient for the stable operation of biogas electricity generators. “As a result, biogas is often simply burnt up, but if we could combine it with biogas produced from empty fruit bunches, it would be enough to stabilise the inflow to the generators.” A country like Malaysia is the ideal partner to develop and launch such a technology. “Companies there are aware of the need to commit to corporate social responsibility in order to keep selling their products.”

Elsewhere in the region, e.g. in Papua New Guinea or Myanmar, the situation is different, however. “Palm oil companies are much smaller there. When larger companies move in to take over, that is not always done in the nicest possible way, creating problems for local communities.” Ironically, countries with a growing palm oil industry score high on economic development, but locals seldom benefit. Rather, they are confronted with pollution, and with prices for drinking water and electricity spiralling due to increased demand.

Empowerment

Lindeboom, Al-Muraisy and Ismail believe that the answer lies in involving local growers at an early stage. “Small companies can leapfrog part of the transition towards sustainability, speeding up the process.” They aim to provide local farmers with the means to convert organic waste from their oil palms into biogas. “They can use this biogas to cook on, but they could also use it to process the palm fruits further, so it is ready to be used in factories. That way, you create a market of small local producers working bottom-up, and empower them in their negotiation with larger companies.” Small farmers need crops that provide them with a constant income, a reality that is often overlooked. “Oil palms are a safe choice for such farmers, as long as they are not forced to sell up.”

To this end, Lindeboom and Al-Muraisy are determined to develop frugal, easy to maintain technology. Lindeboom: “A reactor for the fermentation of empty fruit bunches is basically a closed vessel with micro-organisms. That is not a difficult process to start up, but you need to get the starting conditions right. And you need to understand the local situation. So it is a good thing Al-Muraisy joined the project.” Before coming to Delft, Al-Muraisy studied and lived in Malaysia for 6 years. During his studies, already focussing on palm oil and environmental engineering, he visited a number of smaller and larger growers. “I saw the local situation, the challenges and the opportunities. Therefore, I believe we can contribute to the industry and make a change.”

Robustness

Robust and low-maintenance are key words in frugal design. “You could design a bio reactor that fills and empties itself, without the need for a high-maintenance pump with many parts”, he gives as an example. Such a design philosophy may seem far removed from his previous work at Ghent University, where he designed a closed system for the recovery of water and nutrients from urine for use in space travel. Lindeboom: “In space exploration, technology should work at the push of a button and never fail, meaning it has to be just as robust and low-maintenance.” Making a sustainable palm oil industry not such a moonshot after all, but rather a down-to-earth, attainable goal.