Enhanced Battolyser stores electricity four times faster than before

A new 3D design for electrodes enables the Battolyser™, a battery and electrolyser in one, to store twice the amount of electricity it could previously hold and do so four times faster. Researchers from Delft University of Technology have detailed their findings in the scientific journal Cell Reports Physical Science. The Battolyser now charges and produces hydrogen at a rate comparable to current electrolysers, all without relying on scarce precious metals. This increased capacity saves both space and costs.

Energy storage

To facilitate the energy transition, we need two types of storage for renewable energy: batteries for day and night storage and hydrogen for seasonal storage. The Battolyser™, a hybrid battery and electrolyser, serves both functions with a single device. Additionally, electrolysis powered by renewable energy produces green hydrogen, unlike conventional hydrogen production methods that rely on fossil fuels. Professor Fokko Mulder conceived the Battolyser concept in 2013, which later evolved into a spin-off in 2018 and entered the market in 2021 as Battolyser Systems.

More electricity and switchable

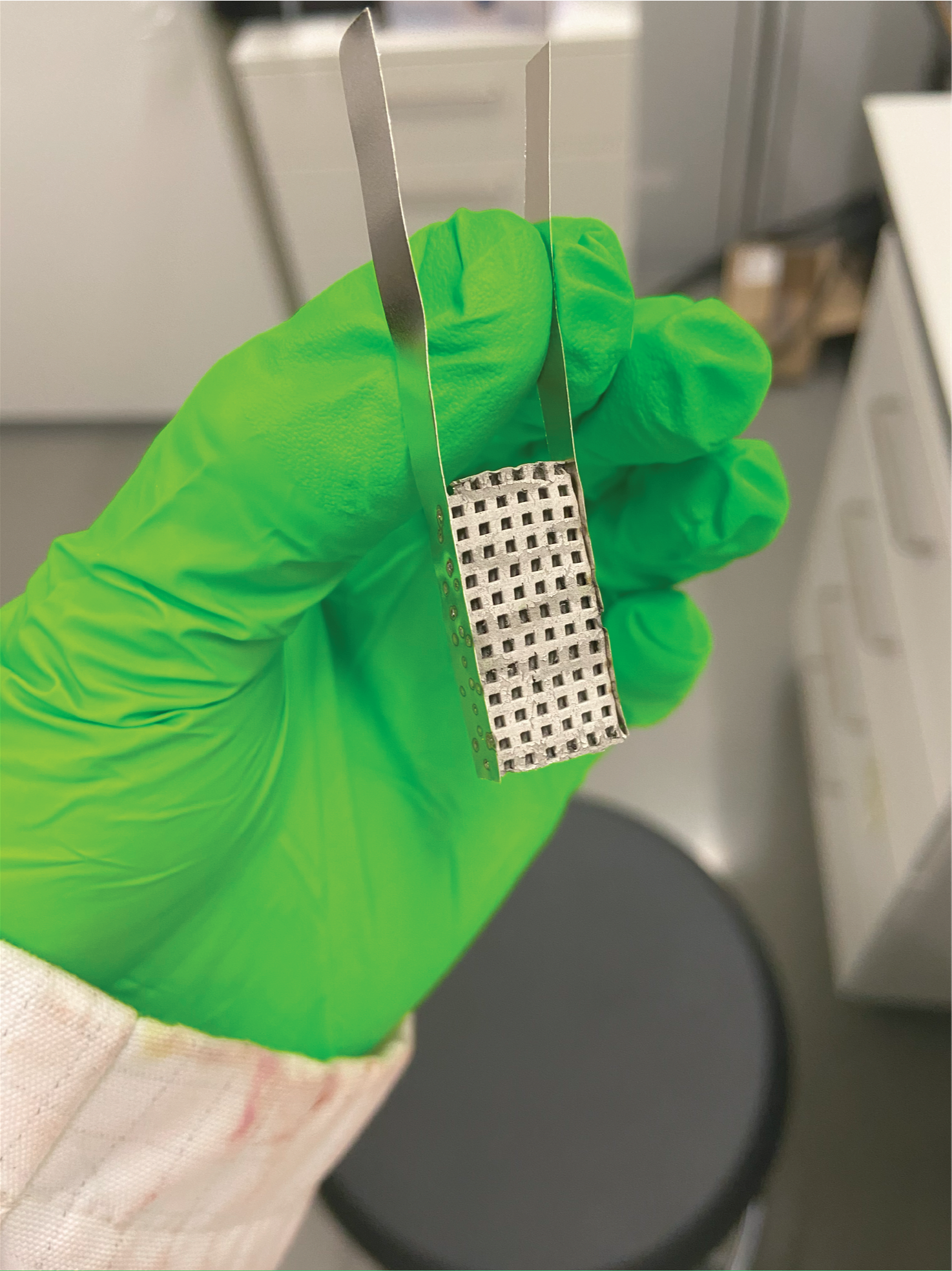

Thanks to the innovative 3D electrode design, the Battolyser can now store twice the amount of electricity and does so up to four times faster than before. This enables the Battolyser to charge and produce hydrogen at a rate comparable to existing electrolysers, without relying on rare precious metals. It can also switch between charging and electrolysis to discharging, a feature that standard electrolysers lack.

Reduced space and costs

The new electrodes enhance the flow of electricity through the Battolyser and improve the efficiency of gas removal during electrolysis, explains Mulder. “This saves space and costs, as these more powerful electrodes mean we need to produce fewer cells. Consequently, fewer cells are required to store the same amount of charge while they can produce more hydrogen.”

“To illustrate the potential space savings: with this upgrade, we could replace a planned Eneco electrolyser covering 20 football pitches and a GIGA Storage lithium battery spanning 15 football pitches with a Battolyser that is only as large as the electrolyser itself,” Mulder adds.

“With fewer cells, we also require fewer expensive components, such as membranes that separate hydrogen and oxygen, and current collectors that direct electricity to the electrodes,” the physicist continues. “Using four times fewer materials for the cells translates to a 75% reduction in material costs. This should lead to lower material usage and costs as we scale up.”

The green energy market

Lead author Robin Möller-Gulland investigated how to enhance the charging speed and capacity of the Battolyser for his doctoral research. Together with Mulder, he developed the new electrode structure featuring channels for electrolyte to improve conductivity. The goal was for the battery to charge for at least an hour and discharge in four hours, matching the charging speed of an electrolyser without precious metals. Mulder: “This aligns well with the needs of the green energy market in the future, as peaks in energy surplus and shortages typically occur over approximately four hours. During this time, both (dis)charging and hydrogen production must be realised.” Möller-Gulland adds that the charging speed has also improved: “Achieving 82% charge in just 18 minutes is now possible without sacrificing battery capacity.”

Patent application and funding

The Delft researchers have applied for a patent for the new electrode design. They received funding for their research from the Dutch Research Council NWO (NWO-TTW) and a consortium of companies, including Battolyser Systems as a member of the user group. In September of this year, Battolyser Systems secured €30 million in funding for the next generation of electrolyser technology.

The Battolyser

The Battolyser™ is switchable, meaning it can turn off and even supply power back to the grid during periods of green energy shortage. Other electrolysers still need to use electricity when there is no wind or sunlight; otherwise, they become unsafe and fail too quickly. Additionally, the Battolyser is scalable, as it does not contain scarce materials like noble metals.

Fokko Mulder

Full Professor

- +31 (0)15 27 85037

- F.M.Mulder@tudelft.nl

- Personal page

-

Building 58, D1.320

Van der Maasweg 9

2629 HZ Delft

The Netherlands