Students present improvements to manure-cleaning robot

A robot that cleans cowsheds. 95 Master Robotics students have been working on this project for the past few weeks. On 13 June, they presented their robots to lecturers and client Lely, manufacturer of automated systems for dairy farmers. The students developed the control software for the robot. It had to avoid cows and other obstacles and navigate itself to places where there is manure.

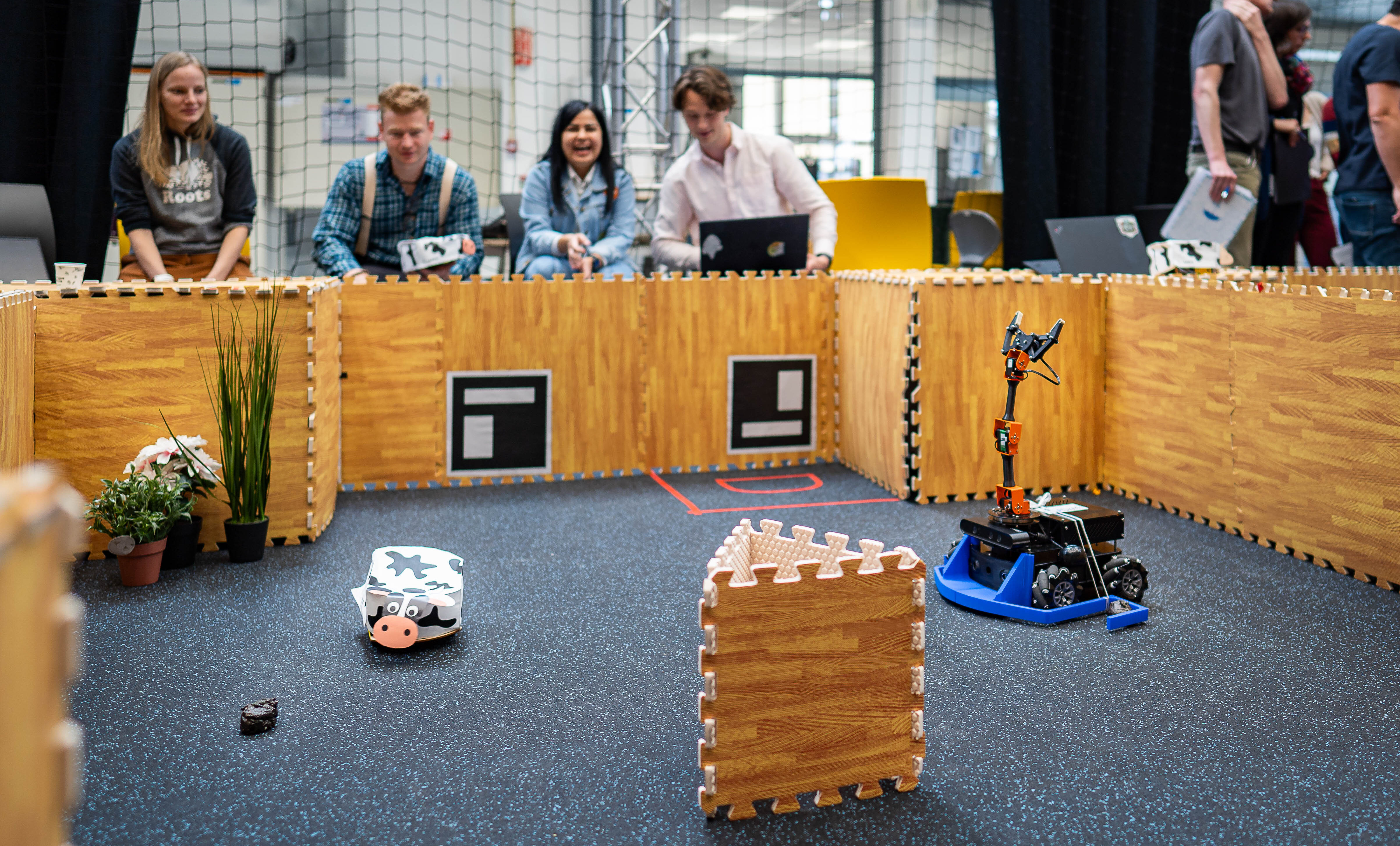

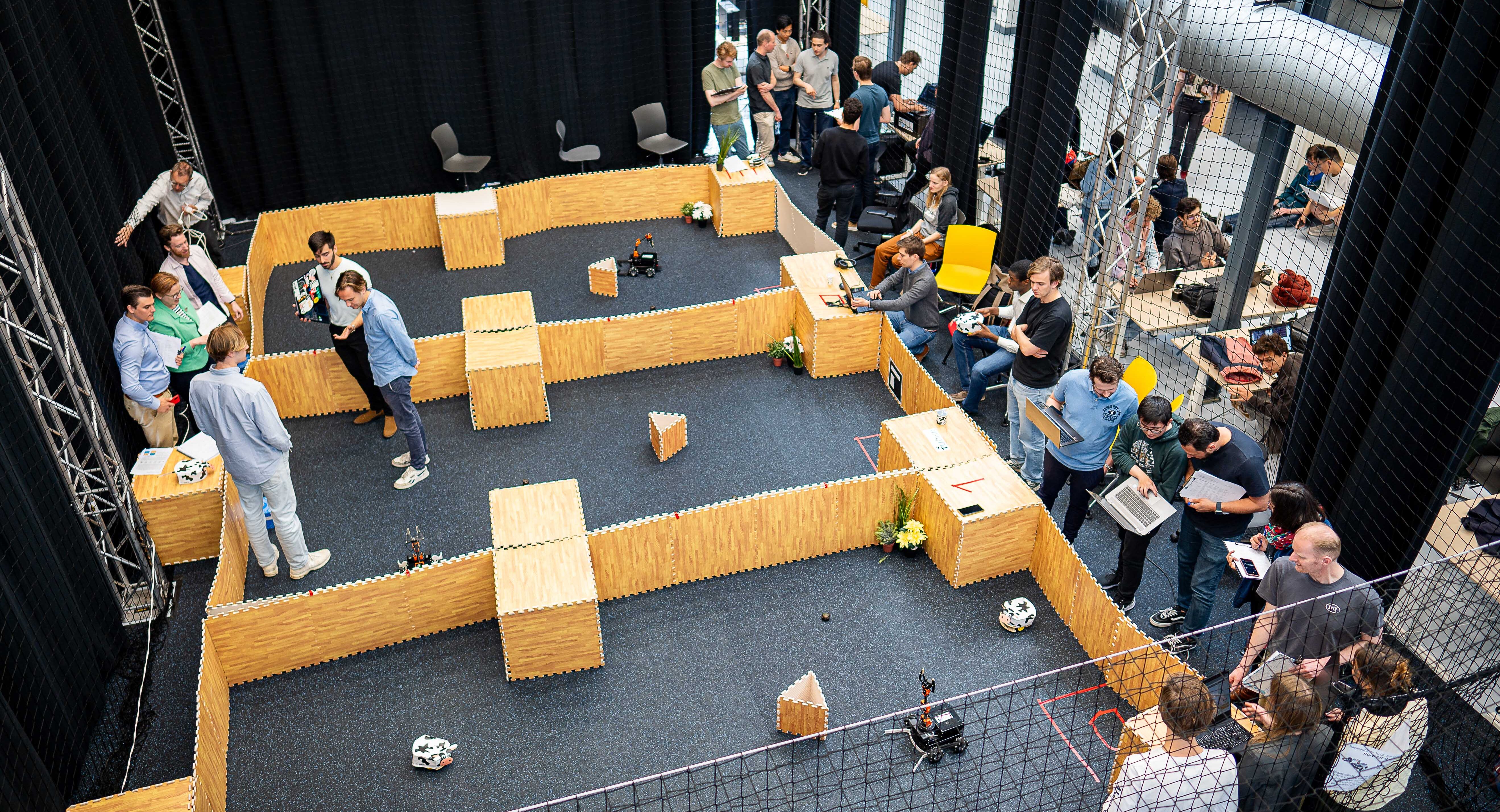

The Cognitive Robotics lab was partially transformed into a mini-cowshed simulation on 13 June. Moving robots simulated the ‘cows’ and plastic cowpats were placed on the floor in between. Around 20 student groups spent the last few weeks working on the control system for an existing Lely manure cleaning robot. The control system was tested on the MIRTE Master robots built by the Cognitive Robotics department. The MIRTE Master is a wheeled robot with a two-finger gripper. The aim was to have the robot detect and remove manure independently, avoid objects and robotic cows, and be easy to operate.

Animal welfare

A tough task, agree project tutors Gillian Saunders and Chris Pek. ‘There’s a lot involved,’ explains Pek. ‘For example, it’s not only important that the robot finds and removes manure without bumping into anything, but it also has to be easy to use and animal-friendly.’ This ranges from the safe design of the robot to the sound it makes to alert the cows that it is nearby. It should not cause them to panic.

Own company

Saunders and Pek set up their own consulting company, MDP Inc, for this project. The idea is to prepare the students as well as possible for their future work field. ‘In designing the course, we took inspiration from industry,’ says Saunders. ‘Some examples include the guidelines for documenting technological developments, writing and testing code, and the different ways of working on projects, such as agile.’

The winners

After all the groups had demonstrated the capabilities of their robots, they were judged by lecturers and Lely employees. The jury paid particular attention to how many cowpats the robots cleaned up, the robots’ behaviour around the cows, the robots’ communication with the farmer about the cleaning status and how the groups presented the robot in their pitch. In the end, group 7 “Betsy” (Levijn de Jager, Wimer Leijendekker, Xavier Reparon, Jules Zwanen and Frits van Hall) won the first prize. They will be able to present their work at a major robotics conference in Delft in July.