Rocket launch 1st April: sending graphene into space for the first time

Friday 1st April is a big day for the study of 2D materials (and no joke): a SpaceX rocket launch will take place that includes a research satellite which contains the first graphene conductors ever to enter space, made in Delft. In two months’ time, we will know how graphene behaves in space. What made it possible: the discovery by TU Delft researchers how to protect the graphene from environmental influences.

Three years ago, researchers from the TU Delft and University of Chile started the project in order to measure how the intrinsic properties of the two-dimensional nanomaterial graphene change in space. Combining the expertise of physicists, 2D nanoscientists and space engineers, their ambition is to make 2D nanomaterials suitable for space application. Laboratory-based studies indicate that graphene, a one-atom thick layer of carbon atoms, should be able to withstand the harsh conditions in space, but this has never been tried before – until now.

2D material in space for the first time

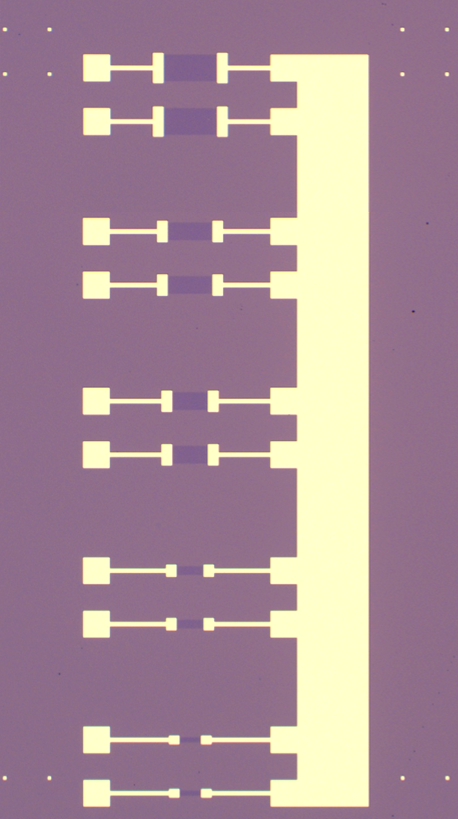

Applied physics master student Kaj Dockx and supervisor Herre van der Zant from TU Delft collaborate with the campus-based company Applied Nanolayers (ANL) for the project. “One of the main reasons we are sending out these graphene devices is that we want to see whether they can withstand the harsh conditions in space, like prolonged exposure to strong radiation and changes in temperature,” Kaj Dockx explains. “If so, graphene would be very useful to apply to magnetic sensors for example, or radiation detectors for astronomical observations. To our knowledge, never before has anyone actually tried sending graphene into space to see what happens.”

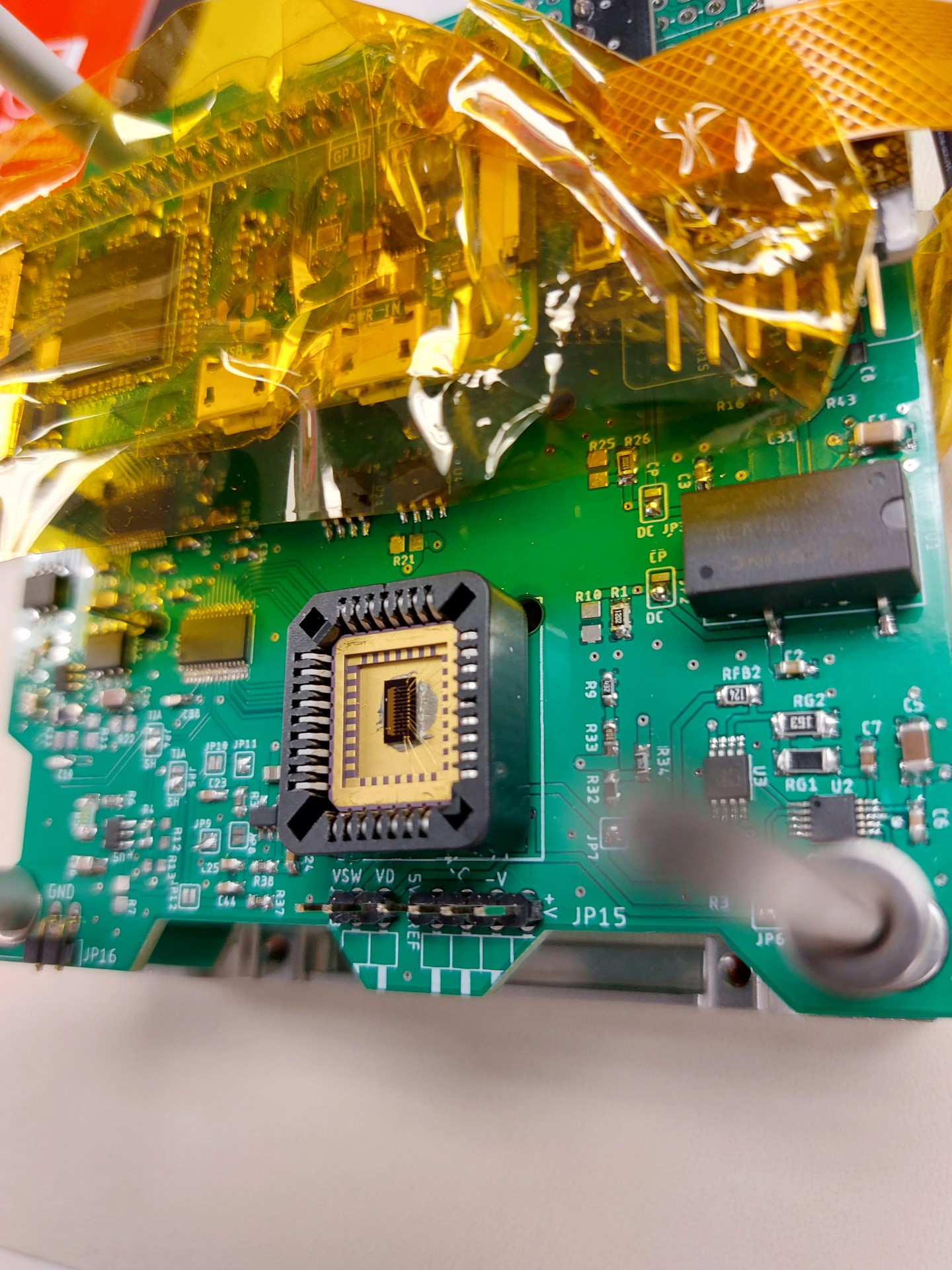

Dockx used an insulating layer on top of the graphene, a crucial step in protecting the 2D devices from environmental influences before and during launch: “Using atomic layer deposition, I encapsulated the graphene with a thin layer of aluminum oxide to try and shield it from the environment. It turns out this process does not damage the fragile graphene layer and works well as a protection against outside influences: around 80% of the samples remained very stable after all necessary transits from Delft to Chile and Cape Canaveral in Florida. The expertise of ANL in graphene production and device fabrication has been essential for this discovery.”

Master students do all the work

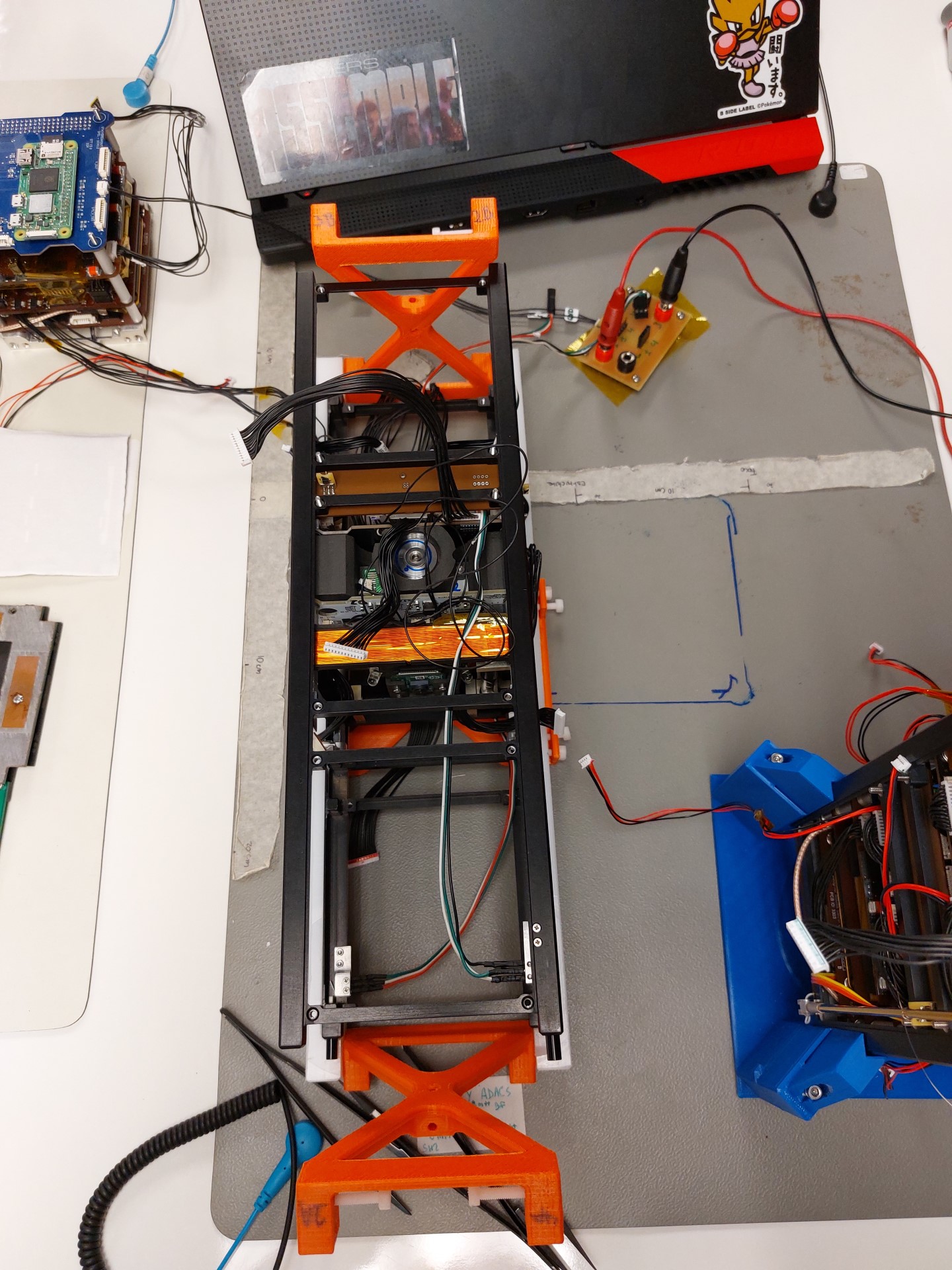

Herre van der Zant explains the other challenges that the researchers had to overcome for the mission: “The samples have to undergo extensive vibration tests to see if they will withstand all the shocks of the launch. Also, the first time we made the transistors they got blown up because they were too fragile for the rocket engineers to handle, so we needed to make them stronger.” What makes the project special according to Van der Zant, is the fact that almost all the work was done by master students. The researchers will have to wait two months before the satellite reaches the desired orbit around the earth, in order to start the measurements and receive the data.