New route to build materials out of tiny particles

Researcher Laura Rossi and her group at TU Delft have found a new way to build synthetic materials out of tiny glass particles – so-called colloids. Together with their colleagues from Queen’s University and the University of Amsterdam, they showed that they can simply use the shape of these colloids to make interesting building blocks for new materials, regardless of other properties of the colloidal particles. Rossi: “This is striking, because it opens up a completely new way to think about materials design.” Their work is published in Science Advances today.

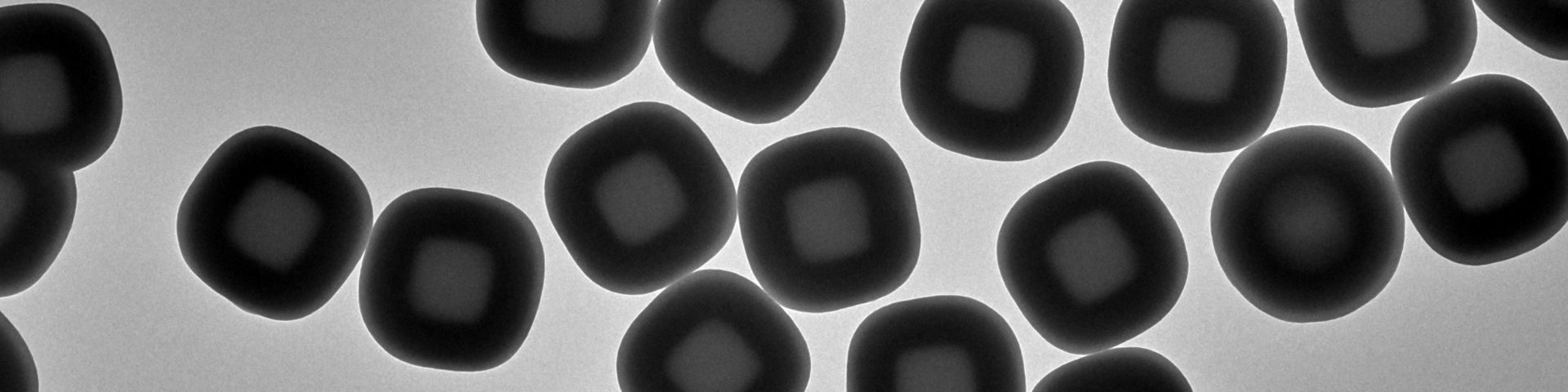

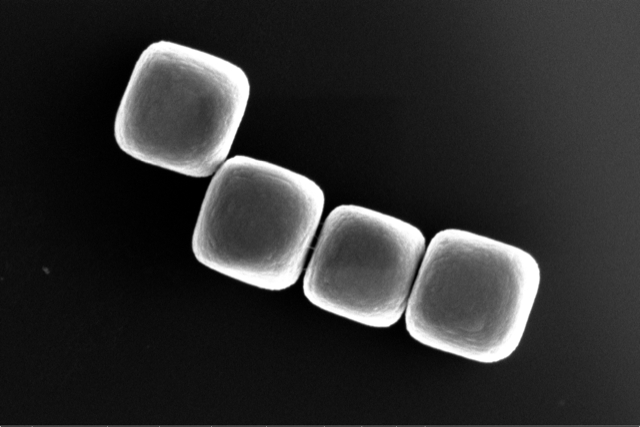

Colloids are tiny particles, a few nanometres to a few microns in size. They consist of a collection of molecules and can have different properties depending on the material they are made of. “Under certain circumstances colloids can behave like atoms and molecules, but their interactions are less strong,” Rossi explains. “That makes them promising building blocks for new materials, for example for interactive materials that can adapt their properties to their environment.”

New way of materials design

If left alone, the cube-shaped colloids from this study, which are made from glass, will assemble themselves into simple structures like distorted cubic and hexagonal lattices. But instead of going immediately from the building block to the final structure, the researchers took small groups of colloids and combined them into bigger building blocks. When they assembled these clusters of colloids, they ended up with a different final structure with different material properties than the self-assembled structure.

“From a chemistry point of view, we always focus on how we can produce a certain type of colloid,” Rossi says. “In this study, we’ve shifted our focus to: how can we use the colloids that are already available to make interesting building blocks?”

A step forward

According to Rossi and her collaborator Greg van Anders, one of the ultimate goals of their research community is to design complex colloidal structures on demand. Rossi: “What we found here is very important, because for possible applications, we need to have procedures that can be scaled up, which is something that will be hard to achieve with most currently available approaches.” “The basic ability to pre-assemble identical pieces from different building blocks, and have them make the same structure, or to take the same building block and pre-assemble different pieces that make different structures, are really the basic ‘chess moves’ for engineering complex structures,” adds Van Anders.

Although Rossi studies the fundamental aspects rather than the applications of materials design, she can envision eventual applications for this specific work: “We found that the density of the structure that we prepared was much lower than the density of the structure you would obtain by using the starting building blocks. So you can think about strong but lightweight materials for transportation.”

Teaming up

After Rossi’s team built clusters of colloids in the lab, they relied on the team of Greg van Anders from Queen’s University to build the final structure out of pre-assembled clusters with a computer simulation. “With these kinds of projects, it’s great to be able to team up with others who can run simulations, not only to understand what’s happening in depth, but also to test how big the chance of a successful lab experiment will be,” Rossi explains. “And in this case, we got very convincing results that we were understanding the design process well and that the resulting material can be useful.”

The next step will be to actually build the final structure made from the groups of colloids in the lab. “After seeing these results, I’m confident that it can be done,” says Rossi. “It would be great to have a physical version of this material and hold it in my hand.”