3D printed component makes snorkel mask useful for medics

IDE researchers, in collaboration with physicians and industry, designed a unique 3D printed connector to connect an ordinary snorkel mask to a filter system. This makes the snorkel mask usable as a protective mask for medical personnel.

Important update! (date: 07-04-2020)

The latest test results show that the CovidLifeSaver Mask (the full-face snorkel mask with a high-performance filter) currently fails to meet the FFP safety standards. At this moment we advise against the use of the mask. The result is dependent on the fit of the mask on the test subject's face when inhaling, which creates negative air pressure. This creates a situation where unfiltered air can still enter the mask. At this current state of development it is unsafe for use in a clinical setting. For this reason we feel compelled to remove our open source designs from Thingiverse. The positive pressure system which is under development does not show this undesirable effect.

Text updated on 08-04-2020

due to the release of new results

The “COVID Lifesaver Mask” and the “Air-Wave Protector”

There is a worldwide shortage of personal protective materials for healthcare professionals due to the COVID-19 pandemic. Two new reusable face masks for medical staff who are caring for and treating COVID-19 patients have been developed in the Netherlands by teams of anaesthesiologists, universities and a consortium of companies, all supporting on a not-for-profit basis.

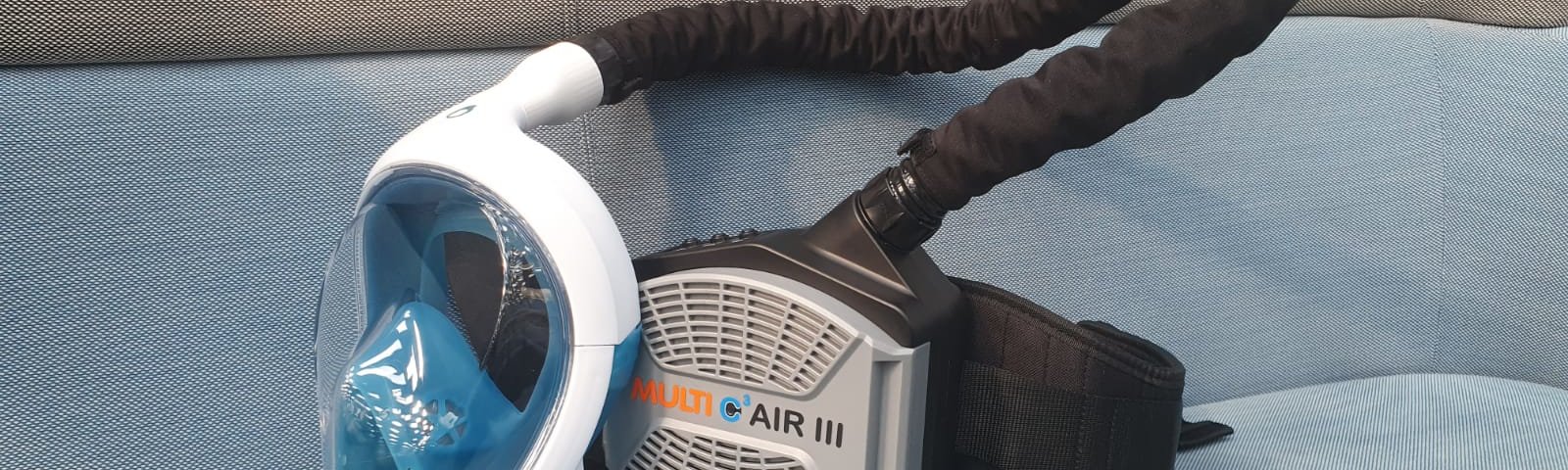

Both masks use a unique 3D printed connector to link a popular snorkel mask to a filter system. The COVID Lifesaver Mask uses a high-performance filter used in anaesthetic equipment to create a low-cost, easy to use system for short duration use. The Air-Wave Protector solution uses an industrial fan & filter unit to create a personal protection unit for use of longer duration.

Air-Wave Protector

The Air-Wave Protector is a combination of a full face snorkelmask connected with a custom 3D printed connector to a medical-grade filter and an air pump used in the welding industry for personal protection. The air pump creates a positive pressure in the mask, potentially reducing air leakage and promoting the ease of breathing. Preliminary testing indicates that the solution provides better protection than the commonly used FFP2 masks. The COVID Lifesaver Mask, which was developed at the same time, does not yet meet the required safety standards in a clinical setting.

Safety and comfort

Inside the mask, glasses can be worn and the mask allows for communication with patients and co-workers. The reusable mask can be decontaminated using readily available cleaning methods. Further tests will take place.

Availability

The designs of the solutions are “open-source” which means they can be freely copied and used to support healthcare professionals worldwide. The design of the 3D-printed connectors created by the TU Delft will be available through “thingiverse.com”, a global website to share 3D print designs. While some aspects of the solutions are still in development and testing continues, the groups have decided to share their designs and progress widely. Royal Dutch Shell has already started printing COVID Lifesaver connectors in its Technology Center in Amsterdam and offered its full cooperation to contribute to the solutions that are being developed.

Collaboration

The not-for-profit initiative has brought together different groups (anaesthesiologists, universities, companies and volunteers) who had similar ideas to help healthcare professionals battle COVID-19. With amazing passion, they have come together to develop solutions in a short period of time.

● A independent group of anaesthesiologists working in Haaglanden Medisch Centrum (HMC), The Netherlands

● Delft University of Technology

● Royal Dutch Shell

● Air-wave.org, a not-for-profit group initiated by Damen Shipyards, Blue Orange Wave, Redgrasp and VFA Solutions with support of a large international group of specialists and innovative companies

Disclaimers

For COVID Lifesaver Mask and the 3D-printed connectors: The design team have done their utmost to ensure a tight fit between the snorkel mask and the HME filter. The current design has been 3D-printed (mostly on Ultimaker printers) and tested successfully multiple times. Since 3D printers can have small deviations in print accuracy, the fit may be imperfect in individual cases. Therefore, every printed part should be checked for individual fit before use. If the printed part has a loose fit or any other defect, it should not be used. Note that the current design can be mounted in two ways to the snorkel mask (front-back rotation). Users should make sure they mount it with the tightest possible fit.