Corrosion is an expensive silent assassin

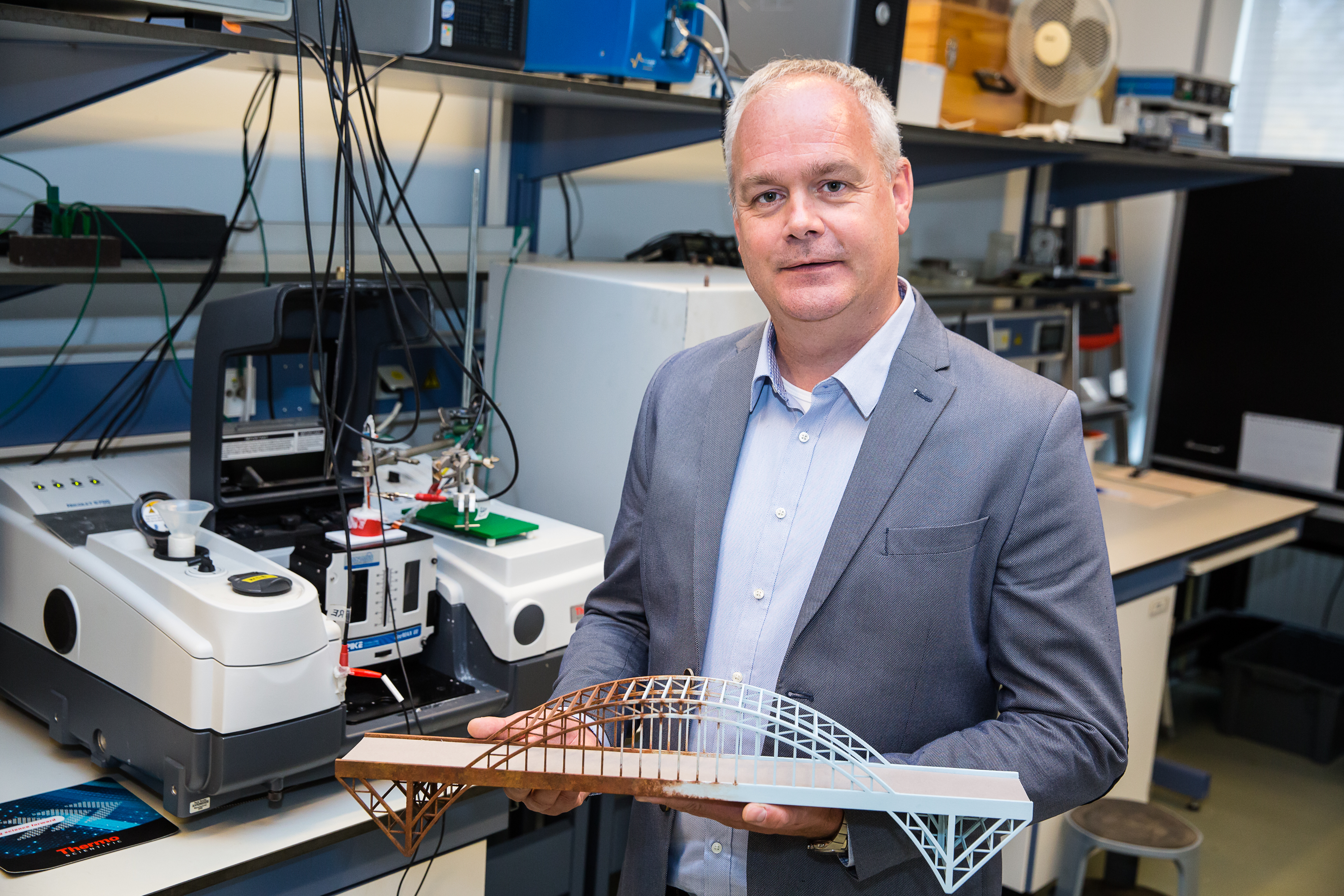

Corrosion can strike hard and unexpectedly, with major consequences in terms of costs and safety. This is according to Arjan Mol, Professor of <link en departments materials-science-and-engineering people corrosion-technology-and-electrochemistry>Corrosion technology and electrochemistry at TU Delft, in his inaugural address ‘Rust Roest’ on Wednesday, 17 April at TU Delft. Good integrated project management can prevent a lot of problems.

Neglected

"In the design and production of metal structures, all aspects of the project are generally taken into account. Unfortunately, corrosion management can often be neglected”, says TU Delft's Prof. Arjan Mol. “There’s often too much focus on price, putting measures to combat corrosion under pressure. As a result, it's highly likely that costs for maintaining and managing a structure will escalate later on. Good corrosion management can prevent this.”

Top priority

Effective protection against corrosion has a positive impact on the condition and lifespan of structures, as well as reducing costs and improving safety.

In Mol's view, well thought-through choices are a top priority in the design process. Properly integrated project management is the key concept in this. "In practice, the main focus is on deadlines and budgets, and integrated corrosion management from design through to the end of the lifespan tends to be ignored”, Mol points out.

“In most cases, you get what you pay for. Low investment costs or ignorance result in high operational costs because the metal has not been effectively pre-treated, or untreated or inferior metals are used. In even worse cases, structural safety can be jeopardised, potentially leading to accidents or environmental damage.”

Alternatives for chromium 6

In the past, the most effective corrosion protection used often involved chromium-based chemistry. Recent developments mean that now the search is on for less damaging solutions. Hexavalent chromium is under pressure from international health and safety regulations, Mol explains. “Alternatives need to be found for that. TU Delft is one of the leading knowledge institutes working with industry to develop them. For instance, there are now very promising pre-treatment systems based on zirconium or trivalent chromium for use as an intermediate coating. For organic coatings too, alternatives are available that are less damaging to the environment and human health. We need to make serious progress in the further introduction of these alternatives, if necessary starting on non-critical secondary components that can be inspected, but it is high time that we acquired more practical experience.”

More information

17 April 2019, starts at 15:00, Aula Building, TU Delft

Inaugural address by Prof. J.M.C. Mol (3mE): Rust Roest

TU Delft Science Communication Adviser Roy Meijer, r.e.t.meijer@tudelft.nl, +31 (0)15 2781751

See also the report on Mol’s appointment