News

TU Delft, Deltares en ProRail gaan spoorverzakkingen structureel aanpakken

ProRail, TU Delft en Deltares doen de komende vijf jaar onderzoek naar het gedrag van rijdende treinen op onze spoordijken en hebben daarvoor op 4 oktober 2021 de overeenkomst voor het Research Program RESET getekend. Dit onderzoek richt zich op de gevolgen van meer, zwaarder treinverkeer met daarbij klimaatverandering voor onze spoordijken en hoe we daar op kunnen inspelen. Er is binnen Europa weinig fundamentele systeem kennis op dit gebied. Dit onderzoek is daarom toonaangevend en kan ook andere landen helpen met gelijksoortige problemen.

In need of technological paradigm shifts

ProRail focuses on automation, digitisation and sustainability

ProRail is facing some major challenges. In response, the Dutch railway infrastructure manager is investing in new digital technologies, such as artificial intelligence and advanced IoT applications. Because of this, ProRail has significantly changed the way it is collaborating with TU Delft. Director of Innovation & Technological Renewal Karel van Gils and R&D programme manager Arjen Zoeteman explain why. “With existing technology, it’s impossible to run more trains after 2030.”

Of course, the quality of the railway network in the Netherlands is indisputable, especially by international standards. It’s one of the world’s most heavily used networks and has high levels of reliability. But despite this, “we’re reaching the limits of the system,” says Van Gils. “Much of our technology still dates back to the 1960s.” Even in work processes, full advantage is not yet being taken of the potential benefits of digitization.

Testing the rails

One mouse click and the iron cross behind the glass groans to life. This is a new test installation to research wear on railway material.

With nearly 100 h.p., the hefty engine can accelerate the 4-metre-wide cross to 1 revolution per second. That is a fairly impressive speed, certainly when you are standing right next to the spectacle. Four times a second, a mini railway wheel races over the mini railway in the basement of the building housing the Faculty of Civil Engineering and Geosciences.

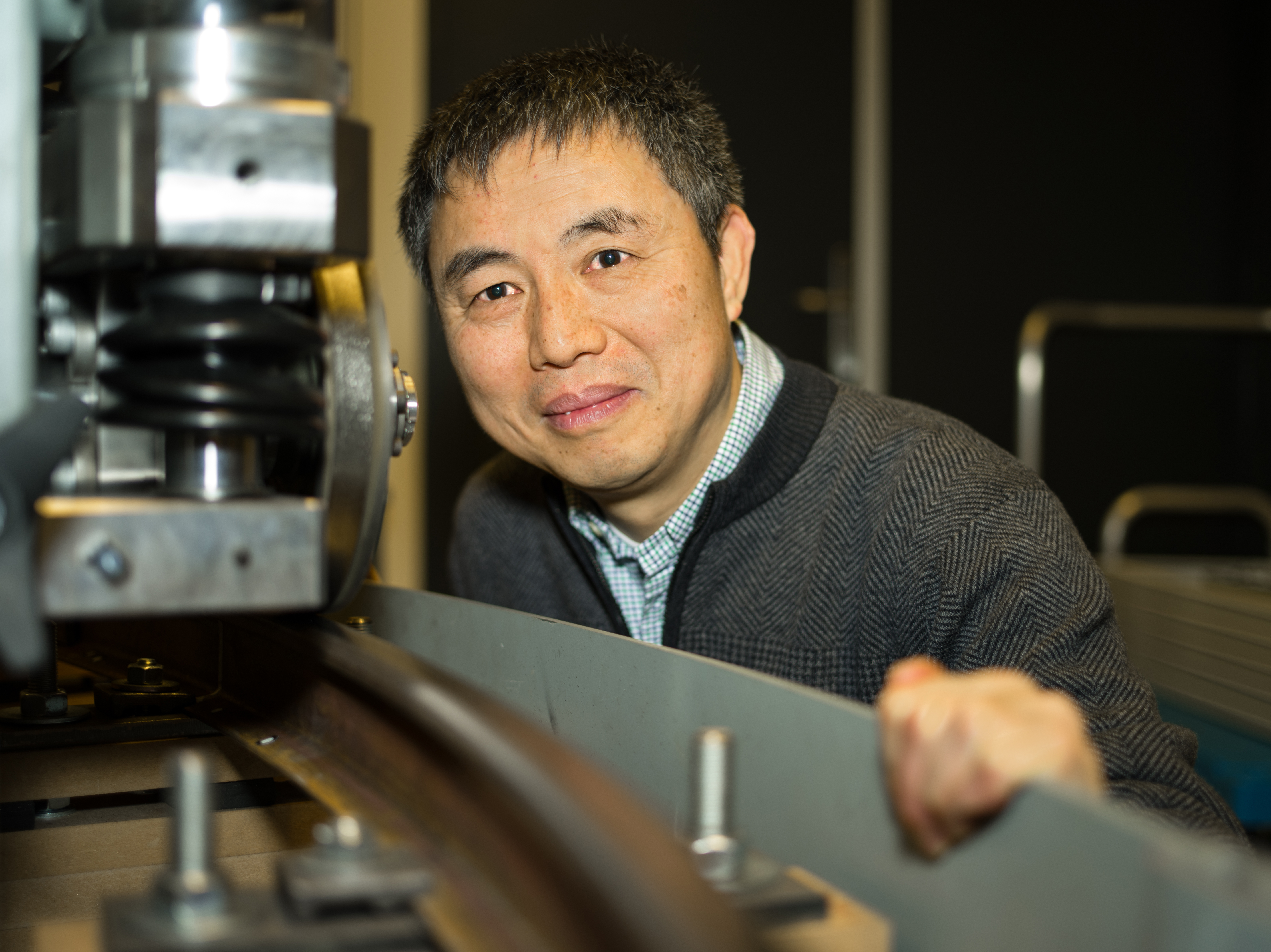

Dr Zili Li watches the installation proudly. He funded the million euros required for the test installation with work conducted by the railway engineering laboratory for external clients over the past decade. “A week on the test track is comparable to a year on the railway network,” explains Li.

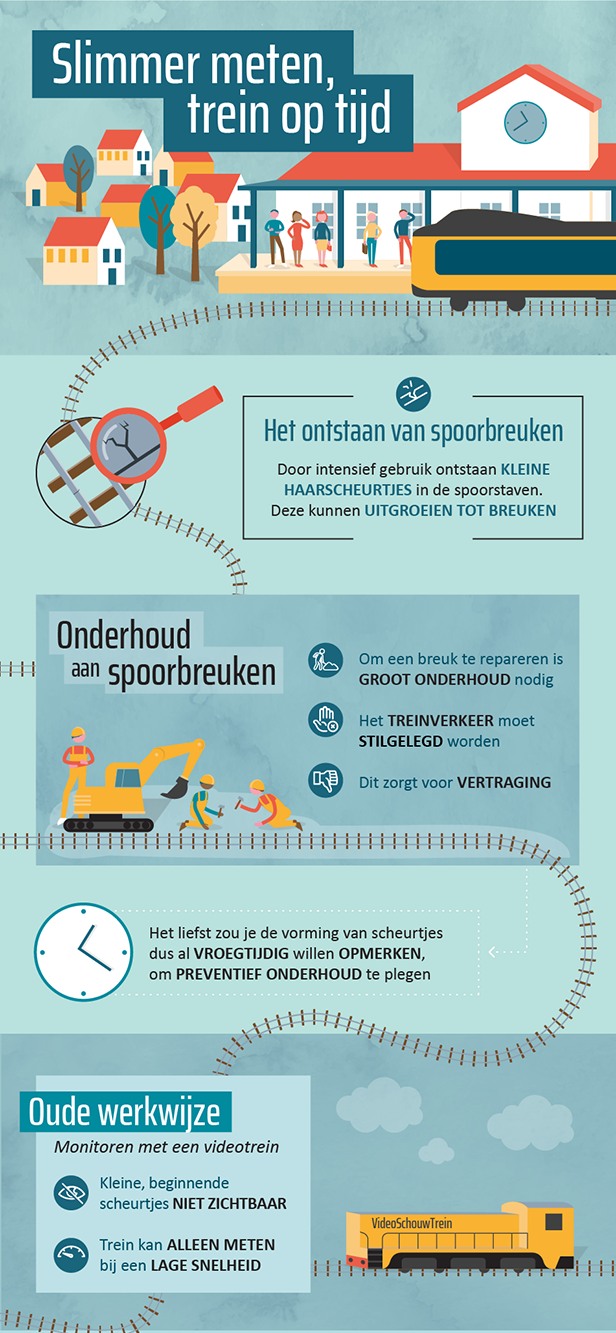

How vibrations indicate the condition of railway tracks

The Dutch railway system will see an increase of traffic and this results in less flexibility for maintenance. The TU Delft contributed to a research project with the objective to reduce disturbances in the Dutch railway system. In cooperation with ProRail a research was performed how small cracks in railway tracks can be discovered in an earlier stage. The new technology measures vibrations of the train and the track.

To inspect the condition of railway tracks, the Dutch railways used a special train equipped with video equipment. The disadvantage of this way is the low speed of this train and this results in delays of the railway operations.

The new technology makes it possible to discover dents, cracks and erosion in an earlier stage. If small cracks in a rail evolve to rail fractures, extensive repair works have to be performed. If small cracks are detected, a train fitted with abrading equipment can repair the damaged tracks after normal train operations.

Zili Li appointed Professor of Rail Systems & Monitoring

TU Delft has appointed Zili Li as Professor in his field Rail Systems & Monitoring at the Faculty of Civil Engineering and Geosciences.

Dr Li has been working in the field of Railway Engineering since 2005 and has become an internationally leading expert in the field of contact mechanics and monitoring. After receiving his PhD from TU Delft and returning there after six years at TNO, Dr Li was the Railway Engineering group leader between Professor Esveld’s departure (2006) and Professor Dollevoet’s arrival in 2012. He passionately kept the Railway Engineering research group running and expanded his own line. He laid the foundations for what is now the Railway Engineering research group.

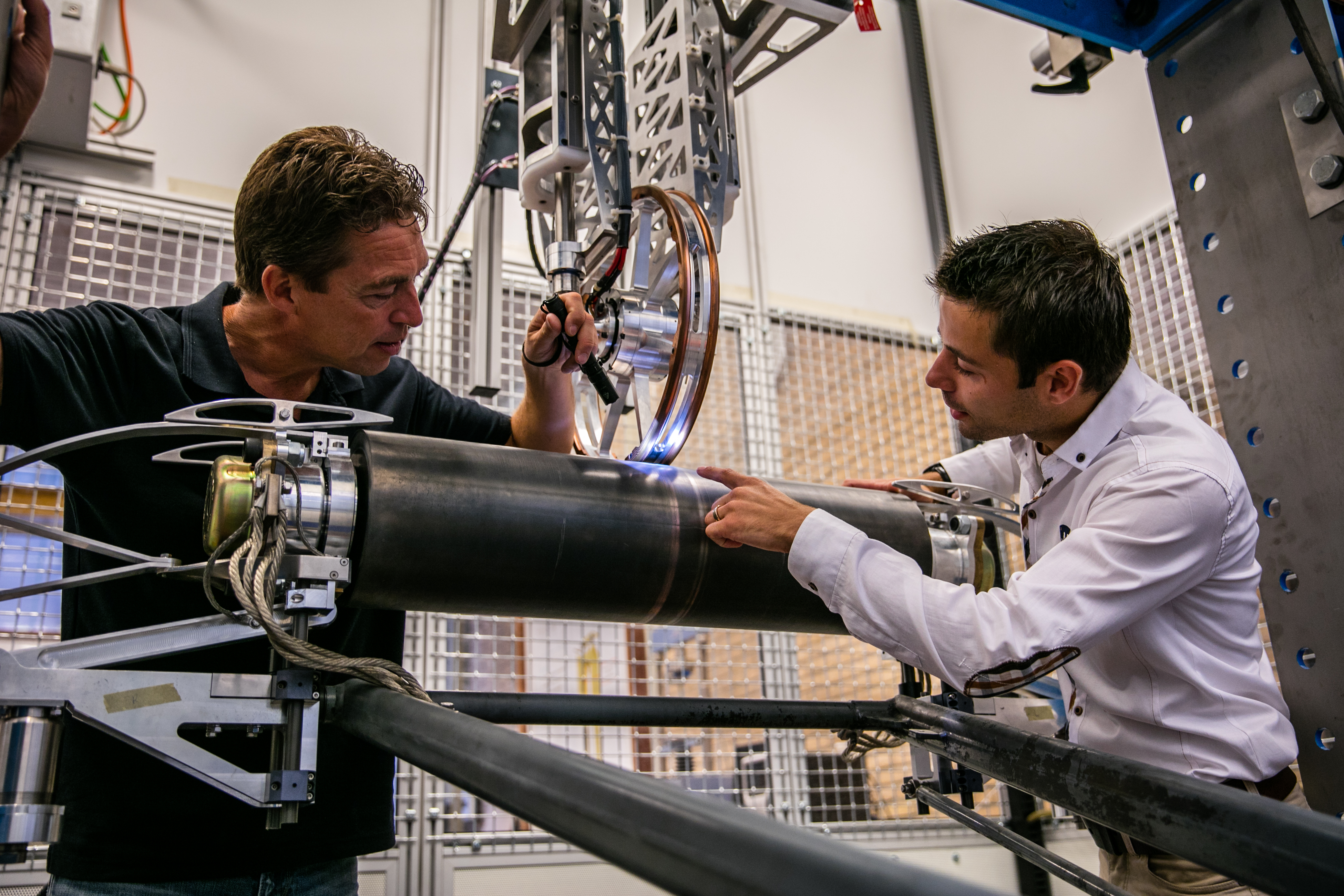

How to keep that rolling stock rolling

Picture an overcrowded platform at Rotterdam central station on a Monday morning. An overhead line on the train link Rotterdam-The Hague has snapped and there are no trains. Chaos reigns in the Randstad. Evert van Veldhuizen and Jan Moraal are experts in the area of pantograph-catenary interaction and if it’s up to them, in the future, a failing overhead line will no longer get the headline news.

The pantograph and the overhead line, or catenary, form a solid team: together they provide the energy the train needs to move. How is it done? The pantograph takes the electricity from the overhead line and feeds it to the train. But wear and tear caused by the prolonged friction between the pantograph and the overhead line weakens the overhead line and can cause it to snap. ‘If an overhead line breaks it comes down, coiling like strand of spaghetti,’ Moraal says. Repairs can take a long time and may affect the adjacent track as well. That means long delays and angry travellers. That is why railway operator ProRail asked Van Veldhuizen and Moraal to find a way of preventing overhead lines from breaking. One of the things they came up with was the rolling pantograph.