Evaporation driven buckling of drops laden with graphene oxide nanosheets

The production of crumpled capsules by spray-drying colloidal suspensions of 2D nanomaterials has received substantial interest, owing to the use of such colloidal structures as surface area enhancers in battery electrode materials and materials for energy storage. Among the different 2D nanomaterials used in spray drying, graphene oxide (GO) has been investigated most often because GO has large surface area, of the order of 2500 sq.m/g which makes them good candidates for energy transition applications. A challenge in producing energy materials from GO in water is the re-stacking of sheets which reduces the available surface area. To overcome this challenge, we investigate the use of spray drying to produce crumpled capsules that do not restack.

Given the experimental difficulties of analysing the process of drop evaporation from macroscopic spray drying experiments involving large numbers of drops, in this work we carry out a systematic investigation of evaporation-induced crumpling of single evaporating drops. The objective to is to understand the physical mechanisms determining the shape of capsules produced by spray drying of colloidal suspensions of 2D nanomaterials, and the conditions determining the onset of buckling.

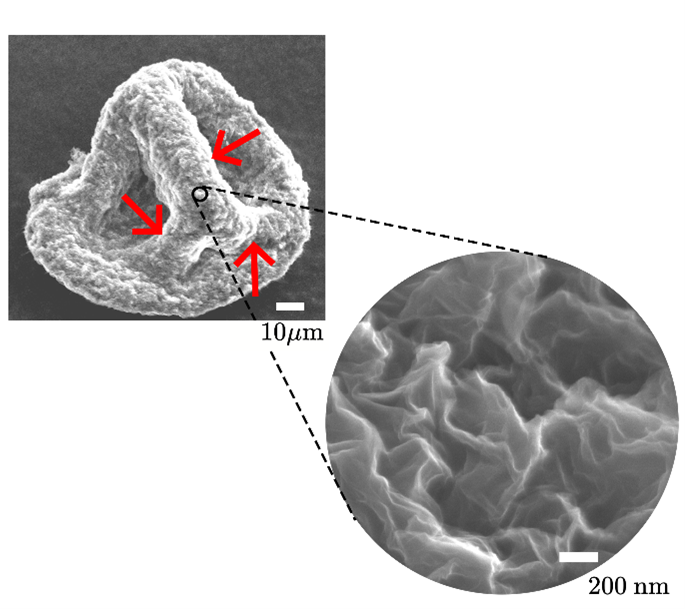

The particle-laden droplet is placed on a super-hydrophobic substrate and observed from the side by a camera. During evaporation the particles accumulate at the fluid interface, forming a semi-solid shell that buckles. The scanning electron microscopy image (SEM) of the buckled capsule in the figure, shows large folds of the order of the capsule size and the inset shows smaller wrinkles of the order of few nanometres. The emergence of such hierarchical folds can be exploited to improve the performance of electrode materials.

By better understanding the morphology of the buckled capsules from evaporation driven buckling, we hope to tune the process parameters in the spray drying in order to obtain optimum high surface area materials.

Chair:

Complex Fluid Processing

Involved People:

Dr. Lorenzo Botto

Suriyaprakash