Heated wire mesh

Contact person: Wiebren de Jong

Description

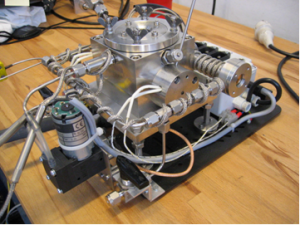

A novel heated wire mesh (HWM) apparatus for solid fuel fast pyrolysis characterisation integrated into a FTIR spectrometer was designed, constructed and tested within a PhD project. The objective was to develop a pyrolysis apparatus that would allow fast devolatilisation experiments (up to ≈1000 K/s) with simultaneous analysis of a wide range of gas species (CO, CO2, CH4, NH3, HCN, HNCO, H2O, C2H2, C2H4) down to ppm levels.

The reaction chamber is cylindrical, enclosed into a stainless steel casing. The mesh is located in the center, it has an area of about 10x12 mm2.

The sample temperature is monitored by a thin S-type (Pt/Pt-Rh) thermocouple of 200 μm diameter. The reaction chamber is connected with the measurement chamber. A circulation pump (flow rate 1 l/min) provides a uniform and constant mixing of the pyrolysis products prior to the FTIR measurements.

The whole apparatus is equipped with trace heating in order to keep it to a stable temperature (up to 150°C) for preventing condensation/adsorption losses. A high quality BK7 glass window on the top part of the case allows optical access to the mesh. In the measuring chamber, ZnSe windows with Ge coating allow IR measurement of the gas products. Two side openings, tilted with an angle of 45°, can be used both as optical access and lighting source points. The reactor can be fed with air for combustion experiments and with Nitrogen or Helium (purity >99.95%) for pyrolysis measurements. The flow of the gases is controlled via accurate mass flow meter/controller.

The setup is controlled via PC using a fast acquisition card (sampling frequency of 103 Hz) and a GUI developed at the Energy Technology section using Testpoint™. The control system is built on an active loop control which modifies the current output during the measurement in order to follow the preset heating ramp. The three control parameters (Peak temperature, heating rate and hold time at peak temperature) can be independently set to the desired values prior to the experiment.

This Heated Grid Reactor allows characterisation of coal and biomass fuels at conditions more relevant to industrial conditions compared to thermogravimetric analysis, such as higher heating rates and peak temperatures experienced by the fuel particles. Moreover tha coupling with the FTIR analyzer allows a further indepth in the processes.

Specifications

Material: Stainless Steel

Chamber volume: About 50 cm3

Mesh size: Approx 10x12 mm2

Tmax: Depending on the mesh material

Heating Rate: Up to 1000K/s

This video shows a plastic flake burning in the Heated Grid Reactor up to 800 °C

A detailed description of this equipment is present in the documents below:

"Biomass fuel characterization for NOx emissions in cofiring applications", PhD Dissertation, Author: G. Di Nola

"Characterisation of supplementary fuels for co-combustion with pulverised coal", PhD Dissertation, Author: J. M. Heikkinen