Mechanical Behaviour Laboratory

Multiscale Mechanical Testing

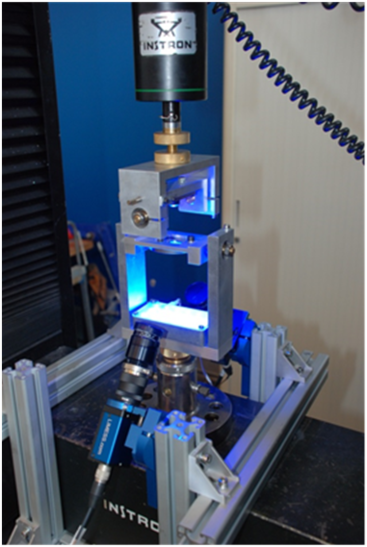

The Mechanical behaviour laboratory offers state-of-the art multiscale destructive and non-destructive facilities available for mechanical testing metals, composites, ceramics, and polymers. The laboratory allows examination of various real-life conditions and parameters that affect material strength and durability due to stress, fatigue, fracture and extreme environments (hydrogen, corrosion, etc). The laboratory is used for education, fundamental and industry-led research.

Responsible Technicians:

Key Equipment:

•1kN to 20kN Biaxial (Torsion) Dynamic mechanical analyzer (DMA)

•25kN Thermo-mechanical fatigue (TMF)

•350kN Servo hydraulic fatigue and fracture machine

•Various static testing machines

•Temperature-assisted (-190oC to 1000oC) testing (upto 350kN)

•In-situ mechanical testing under hydrogen or corrosion environment (high pressure gas and electrochemical)

•Potential drop for crack initiation and growth (DCPD and ACDP)

•Thermal Desorption Spectroscopy (for H, O, N)

•Hydrogen permeation via DS cell

•Potentiostat

•Rotational bending fatigue

•Instrumented Charpy Impact toughness

•In-situ SEM micromechanical tester

•Hardness machines

•Plastometry-based local indentation

•Digital image correlation (DIC) measurements

•Non-contact video extensometers

•Crack Opening Displacement (COD)

•Various Furnaces

•Wear resistant setup

•Sand blasting for surface treatment

•Portable deep freezer