Controlled Cool Logistics: Real-time coordination for fresher food

Background and problem definition

Large number of food products are being transported all over the world. Innovative technological developments are leading to smarter ways to produce and transport fresh products of high quality and more efficiently. Unfortunately, worldwide food spoilage is still severe: roughly one third of food produced for human consumption is wasted throughout the supply chains. Logistics plays an important role in fresh food supply chains. Because during logistics processes, fresh products are often exposed to dynamic environments that can affect how quality of fresh products changes.

The goal of this research

Sensor and communication technologies can bring insights from both logistics and freshness of goods being transported. Therefore, the research goal is as follows:

To design a logistics system which obtains real-time information and performs at higher efficiency and less losses of fresh products.

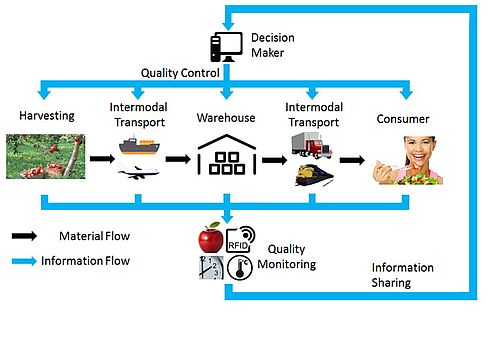

Due to the uncertainty of logistics systems and variability of perishable goods, unexpected situations (e.g., congestions or early ripening) can happen any time during logistic procedures. Thus we propose a controlled logistic system which obtains real-time information, and more importantly, responds accordingly to undesired situations. So that perishable goods supplied in this way could have better quality at a lower price.

Approach

The goal of this research can be divided in the following sub-goals.

- How does environment affect quality of fresh food during supply chains, and how real-time information on environment and quality can be obtained?

- With the real-time information, how does the logistic system plan and reschedule its activities to save the freshness of goods?

- In what way can coordination in logistics be carried out in order to enhance the performance of the supply chains? And can logistic systems adjust its environment to pro-actively adjust the quality of fresh goods according to requirements of freshness or ripening?

The effect that environment has on quality of fresh products needs to be quantified using shelf-life models. Because characteristics of fresh products can be very different from each other, case studies will be carried out to illustrate the performance of the logistic systems. Real-time of freshness can be considered in the planning and real-time. With intermodal transport, the logistic system can be scheduled with higher flexibility. In this study, the approach of model predictive control (MPC) will be used. The layout of the control scheme will be investigated for real-time coordination within logistic systems.

Contact

PhD candidate: X. Lin, MSc

Supervisor: Dr. R.R. Negenborn

Promotor: Prof.dr ir G. Lodewijks

Email: X.Lin@tudelft.nl