Sustainable Design of Large Scale Belt Conveyor Systems

Belt conveyor systems are widely involved in bulk material handling industry. Especially, Large-Scale Belt Conveyor System (LSBCS), in terms of high capacity, speed, and overland distance, plays an important role in dry bulk material transport applications such as in mining industry and power plants. One big challenge, however, is the efficient prediction and maintenance of the numerous idlers that a LSBCS consists. This research aims to develop an Intelligent Decision-Making System (IDMS) for an Automated Maintenance System (AMS) which can fulfil the task of idler maintenance without human involvement.

Background and Question Definition

The idler maintenance lays a big challenge for the industry. For a LSBCS, it may consist of more than thousands of idlers spreading up to 30km. The normal lifetime of each idler roll can be 3 to 5 years depending on the actual in-use conditions. However, the random failure of idler rolls causes higher noise and energy consumption, cuts the conveyor belt or even leads to fire incidents.

Currently, the maintenance of idler rolls is carried out by maintenance crew in manual ways like "looking" and "hearing", or with the assistance of inspection tools. The current maintenance strategy is labour intensive, time consuming as well as risky for the personnel. Even worse, the manual inspection is not reliable and predictive enough, which leads to either too early replacement of healthy rolls, or over late detection of failed rolls.

With the development of robotic techniques, the AMS will be introduced into the idler maintenance of LSBCS in near future. In fact, robot-assisted inspection and replacement of idler rolls have been realized. However, the impediment of the AMS is that an optimum IDMS needs to be developed in order to determine which roll needs to be replaced. This leads to the main question of the research:

How can an IDMS determine which rolls of LSBCS to be replaced?

Objective

The main goal of this research is to develop an IDMS which can detect the impending failure of rolls automatically. Besides that, the knowledge of the load condition and the failure mechanism of idler rolls is produced.

Approach

To achieve the goal, a theoretical analysis of the load condition of idlers, as well as experimental study of the failure detection of idlers are performed.

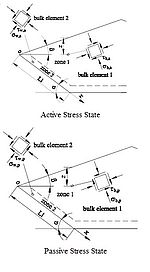

For the load condition analysis, the load distribution among idler rolls due to bulk material and the belt is investigated by using soil mechanics, and taking into account the dynamic cyclic movement of bulk material and the belt. With the achieved load distribution, the analysis of the load condition of journal bearings of each roll can be conducted and a physical failure model of the roll will be developed.

For the experimental study, a test rig for the Idler Endurance Running Experimentation (IERE) is developed. During the experiments, different rolls will be run to failure and the thermography, vibration and acoustic signals will be acquired, analysed and compared. A conclusion will be made on which type of signal is reliable based on the analysis and also including the in-use conditions. A data model of the chosen signal will be developed from which the indicator of the impending failure of a roll can be detected.

lastly, the integration of the physical model and the data model will be explored. The advantages of the two models are combined while the drawbacks will be diminished. With the integrated physics-data model, an IDMS can be developed.

Results

An analytical model of the load distribution among idler rolls is developed, by which the optimization of idler design can be achieved. In addition, a theoretical model of the failure of idler rolls is carried out, and the prediction of lifetime of idler rolls has to be achieved.

The knowledge of the failure mechanism of idler rolls is produced. In addition, conclusions on the detection of the impending failure of rolls is made. Based on the knowledge and conclusions, an IDMS will be developed for the AMS.

Research Team Members

Xiangwei Liu – x.liu-4@tudelft.nl

Yusong Pang – y.pang@tudelft.nl

Gabriel Lodewijks – G.Lodewijks@tudelft.nl