DEM simulation of grabs and cohesive materials

DEM simulation of grabs and cohesive materials

Research of Javad Mohajeri

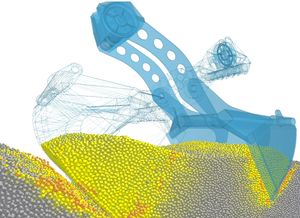

Grabs are usually used to unload dry bulk carriers, which offer a time- and cost-efficient service at destination ports. Grab manufacturers need to design for different crane sizes and various types of bulk materials. Therefore, they are interested in enabling an affordable method to evaluate new designs. Previously, within our research group, Stef Lommen developed a validated co-simulation of grabs and iron ore pellets. In his research, the Discrete Element Method (DEM) was used to simulate bulk behavior of iron ore pellets, which is a free-flowing and relatively incompressible bulk material. However, most of cargoes (e.g. iron ore fines) behave differently when they are moist, usually more compressible and cohesive. It is still unknown how cohesion and compressibility of these bulk materials influence the grabbing process. Therefore, an important part of this research focuses on studying interaction of grabs with cohesive materials using DEM.

Objectives

Iron ore is a cargo with the largest dry bulk trading volume per year due to its high demand in industry, above coal and grains. When bulk carriers arrive at the port of destination, the iron ore cargo is often in a partially consolidated form. However, the exact state of the iron ore cargo remains unknown, as many factors are involved in its production, loading and transportation. For instance, the varying forces that acted upon the cargo during loading and sailing can lead to different states of compaction.

Therefore, the first objective of this research is to characterize the grab relevant bulk properties of iron ore fines in different levels of moisture content and compaction. The grab relevant bulk properties, such as bulk density and penetration resistance are measured in laboratory scale, which will be used for calibrated DEM simulations.

Second, the DEM simulation of cohesive iron ore in interaction with grabs will be developed. To ensure accuracy of the simulation, its output will be compared with the grabbing process of the same cargo in a bulk terminal.

Finally, once a validated simulation of the grab process of iron ore fines is developed, optimization of a grab design can be applied. For grab design application, however, uncertainties and randomness exist in the bulk material properties and interaction of design variables. To ensure robust and reliable designs, we need to account for these uncertainties or randomness in the optimization procedure. Thus, statistical optimization of grab process using the DEM-MBD simulation will be focused in the second phase of the research.

Approach

Since a large scale co-simulation of a grab requires around 70 to 80 m3 of iron ore, the number of elements in the simulation should be minimized. It can be achieved through scaling up size of the DEM particles, where a small group of particles will be replaced by a single coarse particle, which affects accuracy of the calibrated DEM simulation. The accuracy of the large scale simulation of the grab process will be assessed by comparing its predicted results to the outcome of a physical in-situ experiments.

Before being able to improve the grab performance through virtual prototyping, it is essential to identify how the influential factors (controllable and uncontrollable) contribute in the process output. The validated DEM-MBD simulation and the laboratory measurements will be used to study the grab process of iron ore fines in different conditions through DEM-MBD co-simulations.

Funding

This research is supported by grab manufacturer NEMAG B.V., the Netherlands. Their support is gratefully acknowledged.

Contact

Javad Mohajeri - PhD Candidate

Dr.ir. Dingena L. Schott

Prof.dr.ir. Cees van Rhee