Design of Brushless DFIG for Wind Turbines

Modelling and Design of Brushless Doubly Fed Induction Machine for Wind Turbines

Project description

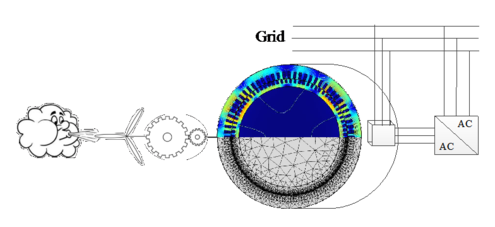

This project is for the development of a Brushless Doubly Fed Induction Machine (BDFIM) as a potential medium-speed generator for wind turbine applications. The BDFIM can operate at a variable speed with a partially rated power converter, like Doubly Fed Induction Machine (DFIM) that is currently the most common generator for wind turbines. The brushes and the slip rings are eliminated resulting in a higher reliability. It also shows a better fault ride-through capability. However, the BDFIM has not yet been commercially available due to its higher manufacturing cost and lower efficiency compared to a DFIM of the same rating. In order to make the BDFIM attractive for commercial applications, this project applies finite element (FE) models to study several aspects of the BDFIM to make its performance achieve the industrial level and multi-MW size. Main project objectives are:

- Establish detailed FE model for analysing complex operating features of BDFIM;

- Establish computationally efficient FE model for the optimization purpose;

- Investigate the influences of detailed effects (e.g. pole-pair combination, saturation etc.) on the machine performance;

- Achieve an optimized design of BDFIM considering its performance, weight and cost.