Did you know that on average people buy a new kitchen once every 20 years? It is usually not the result of the old one no longer being functional but because the kitchen is outdated and people are ready for a change. This unfortunate wastage is out of step with the concept of the circular economy in which we reuse as much as possible. TU Delft is therefore working closely with industry partners to research how kitchens can be made circular: The Circular Kitchen.

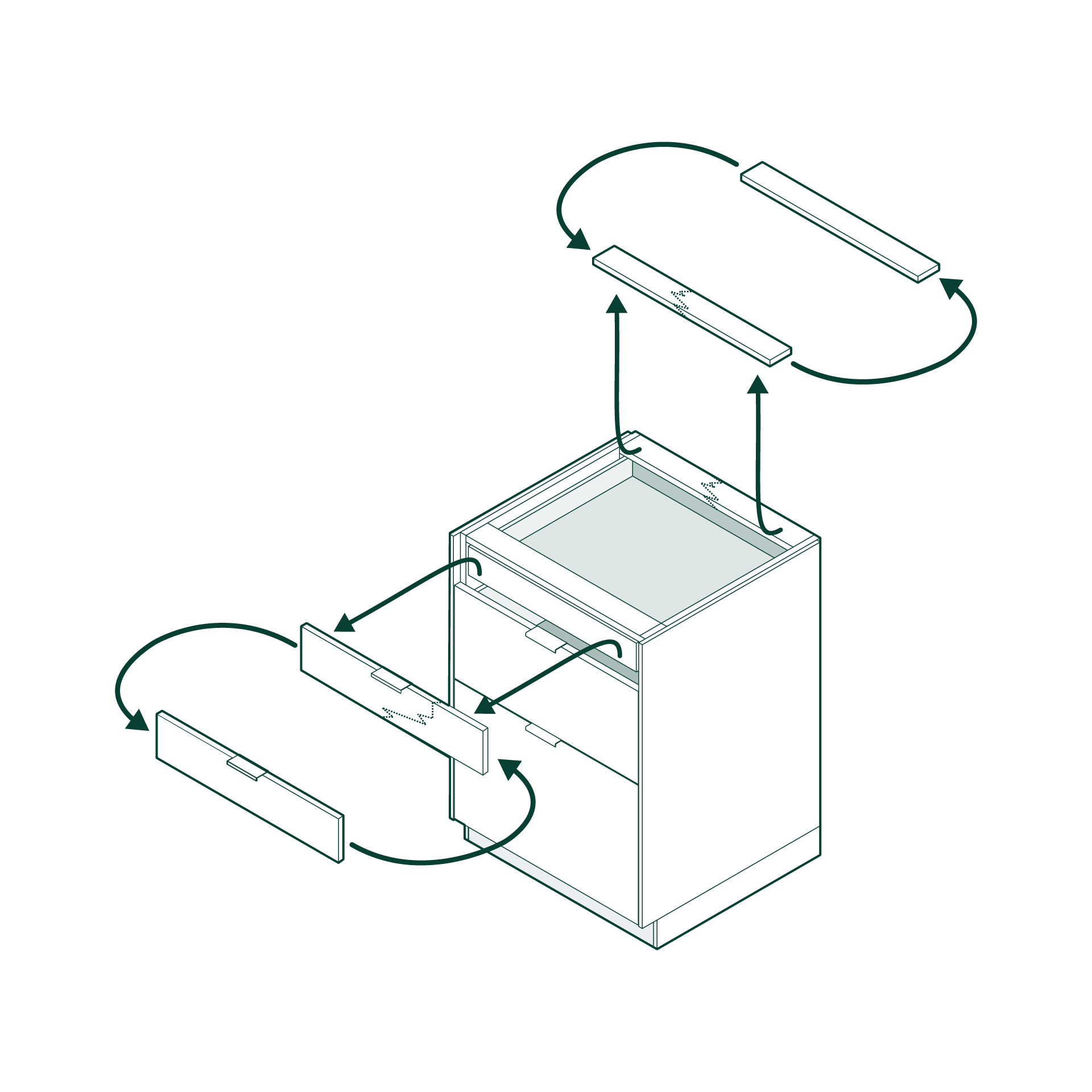

Replaceable modules

Our idea is to construct kitchens from modules with easily replaceable parts. So, after 20 years, instead of buying a whole new kitchen, you can simply buy or lease a new style package. The functional components only need replacing after 40 years and the frame on which everything is installed lasts a lifetime – up to 80 years.

Collection and reuse

The outdated modules are collected and reused or recycled. To facilitate this, we have developed a circular supply chain in which kitchen manufacturers, retailers, housing associations, landlords and consumers work together. This saves raw materials, reduces waste streams and halves the CO2 emissions generated per kitchen.

Wim Diersen, CEO Bribus

At Bribus, we attach great importance to social involvement and this can be seen in our long-term partnerships with customers, suppliers and employees to improve our healthy living environment for current and future generations. The TU Delft‘s CIK research is an innovative collaboration from which Bribus has gathered a lot of knowledge regarding circularity. We want to use this knowledge for further sustainable developments within our business operations.

Sander Jahilo, EIT Climate-KIC

The Circular Kitchen project embodies excellent research skills, strong market-driven stakeholders and ability to put theory into action through constant reiteration and learning – this approach is shared by EIT Climate-KIC as we are constantly looking for ways to increase climate impact through innovation across industries, regions and levers of change.