The university and the people in the university need products to work and fulfil their daily activities. These items procured can be stationary, furniture, equipment, coffee cups, etc. Unless solved in a circular way, all of these create waste flows.

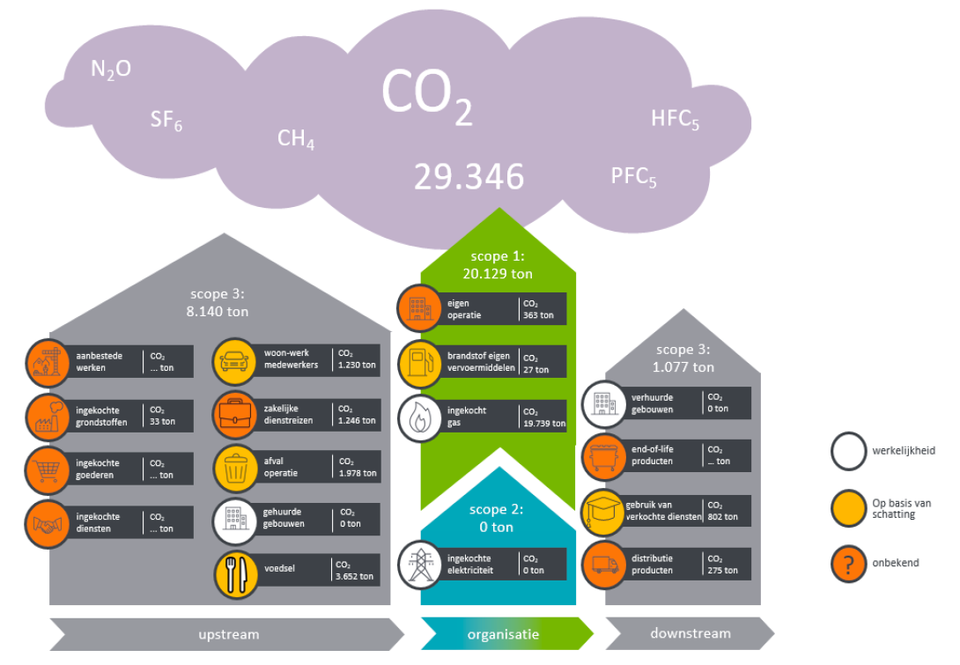

Research by Herth & Blok [2021] clarified that procurement of new items, services and waste management is the largest contributor to carbon equivalent emissions of TU Delft. This is related to the embodied carbon of these purchases and their waste flows. The Procurement & Waste Management team works to reduce the environmental impact of these flows by means of a circular procurement and circular contracting policy.

Circular procurement

Circular procurement is about making the entire supply chain circular, contracting suppliers, for which circularity should be a key element. Avoidance of procurement is best, but when new materials or products are required, only sustainably sourced products will be contracted, without damaging properties or negative externalities, in a geographically hierarchical manner, from local to regional to global. Also, embodied energy and social aspects are taken into account.

Circular contracting

Circular procurement is about making the entire supply chain circular, contracting suppliers, for which circularity should be a key element. In addition, we are exploring other ownership models, such as leasing. In that case, the supplier or producer remains responsible for the product and takes it back if the product no longer meets the requirements.

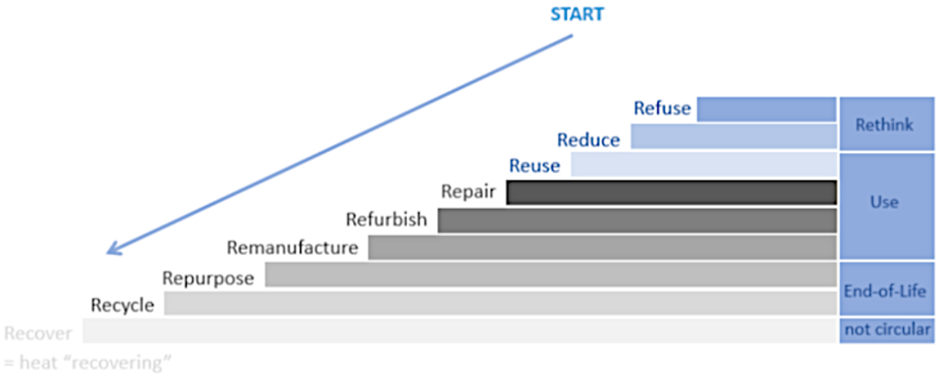

The R-Ladder

Both TU Delft and suppliers must apply the so-called R-hierarchy. The most important steps are refusing, reducing the demand and reusing the residual flows (the top of the ladder). When using the r-ladder, one must not only look at the product as a whole, but also at the elements it is made of. Perhaps only a small element must be repaired or replaced instead of the whole product.

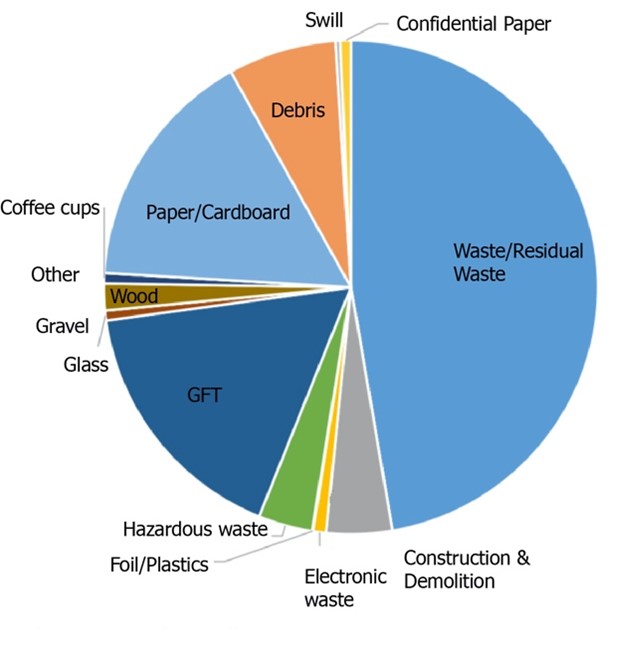

Waste production and processing

In the year 2018, TU Delft produced 2.8 million kg of waste, which is 93 kg per person on campus. To reduce the amount of waste produced, TU Delft is going to use less consumables and disposable products, avoid packaging, and prioritise sustainable and durable goods. Avoidance of waste is better, by better informing staff and students. For the unavoidable waste, there is close collaborate with the waste processing company. An important step is to repair, refurbish, remanufacture, repurpose, recycle or recover matter that is otherwise seen as waste. Finally, the university is looking into the possibility of using algae, bio-fermentation, or biorefinery.