A desire to learn more about building materials brought architect Samanwita Ghosh from Delhi, India to Delft, the Netherlands. Driven by an ambitious research question, she immersed herself in the wonderful world of sheet materials. And came up with a very promising result.

As a Building Technology master’s student Samanwita develops a particular interest in circular facade cladding design concepts. Might there be a renewable alternative for conventional materials like brick, steel and aluminium? “Of course there are historical examples of mud cladding and timber claddings are quite common. But I was looking for a sheet material that can be applied in cladding systems with complex geometries. A material that can be reshaped. Something that would make architects happy.”

Emulating aluminium

The buildings that have the highest environmental impact, Samanwita finds, are typically the tall blocks that contain a lot of glass and aluminium panelling. “Some of the properties that make aluminium so popular are strength and durability. It’s also easy to manufacture and recycle.” On top of that, aluminium sheet material has the ability to bend along a single curve and bend back to a flat sheet without distortion. “Something that we engineers call ‘developability’. It’s a quality we don’t encounter in available bio-based sheet materials.”

She decided to address this shortcoming by trying to develop such a material, taking into account the question of a bio-based material’s durability. “Do we really need sheet material in facades to be as durable as aluminium?” After all, if there’s a bio-based alternative that can meet functional demands there’s no need to mine raw materials and produce industrial metals for claddings. “Just because it isn’t there, doesn’t mean it can’t be made.”

Fibres and resins

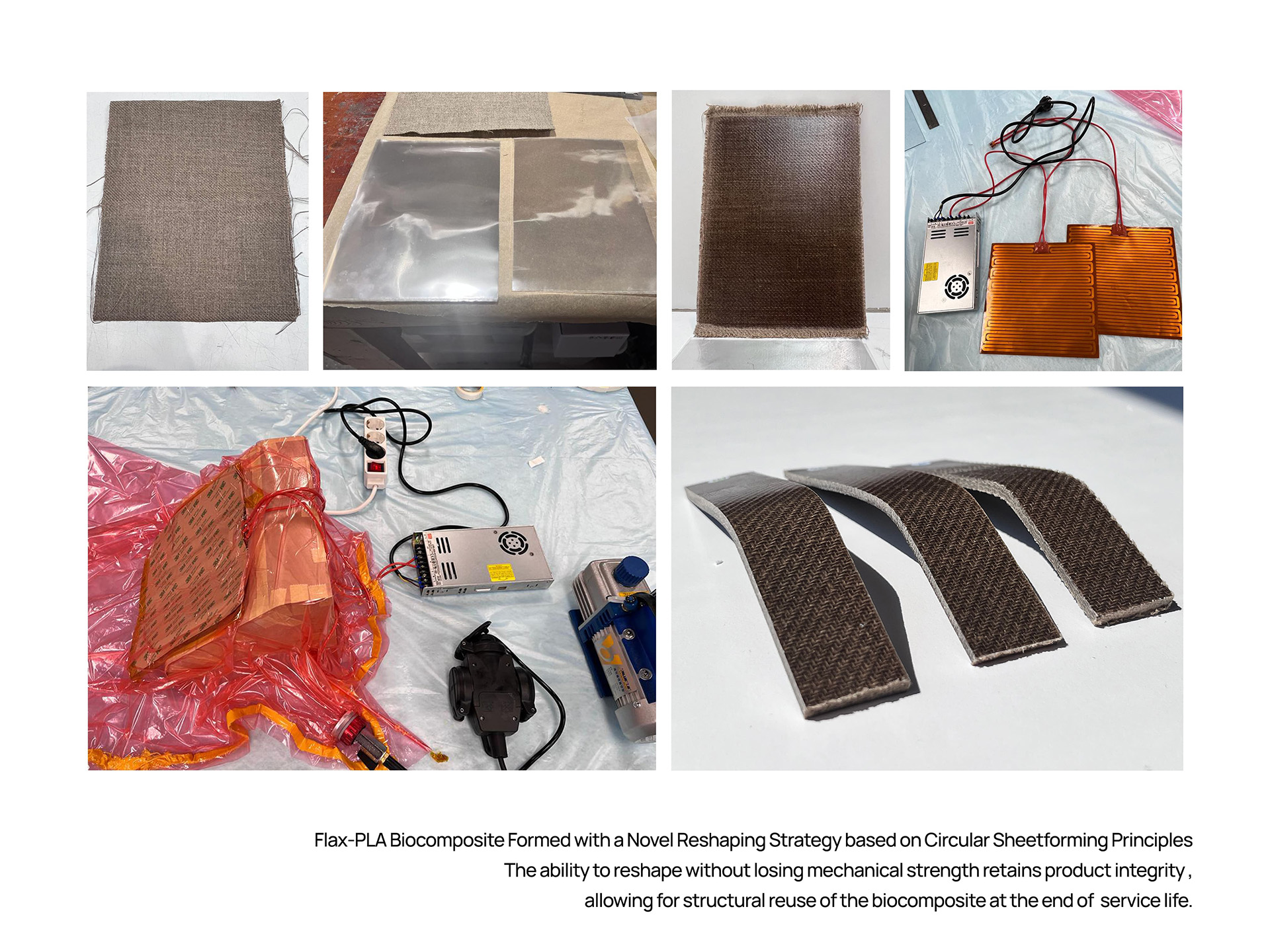

Where to find the right mechanical properties? Reading relevant literature Samanwita stumbled upon natural fibre-reinforced bio-composites. Considering European resources and supply chains she arrived at a combination of flax, as a fibrous material, and a fully bio-based thermoplastic resin. “This bioplastic is made from renewable biomass. And flax is the oldest fibre to circulate the world, usually in the shape of linen. It’s very strong.”

In order to figure out how to engineer the desired product, she studied how industrial sheet material is fabricated. Following a similar procedure, involving hydraulic hot press infusion, she then produced a laminate in collaboration with a biocomposite manufacturing company. “I was able to test its properties at the Faculty of Mechanical Engineering, right here on campus. I performed some mechanical tests to see if the sheet can be bended and then reshaped without distortion. This was the case. The material retained its structural integrity.” She also applied the material outdoors, shaping it on a building. Subject to moisture, wind and sunshine, the surface quality is compromised but the material retains its mechanical strength. “Which means it can be remanufactured and used again.”

Footprints and local crops

The natural raw materials applied in the composite store biogenic carbon: carbon from the soil. So, like timber, while the material is retained it serves as a carbon sink. But what of the carbon footprint that production and transport leave? “My mentors told me to carry out a life cycle assessment, so that I would actually be able to compare the material’s environmental impact to that of aluminium sheet material. It turns out the bio-composite sheet has a significantly lower impact.”

When asked what she considers to be the best part of her research, Samanwita is quite clear. “This bio-composite material can be created anywhere in the world, using native bio-resins and fibres with similar qualities from local crops. In India, this would be jute rather than flax. The method is low-tech and production can be easily scaled up.” A next research challenge, she suggests, would be to enhance the material’s service-life expectancy so that if it is applied cyclically its impact is further reduced.

Samanwita has meanwhile found employment as a materials engineer for the company that helped her carry out the case study. “We develop architectural envelopes for high-rise office buildings so this position is right up my street.”

This story is published: March 2024

More information

The complete thesis is currently under embargo, but will be eventually made available through this link:

Samanwita Ghosh graduated under the supervision of Olga Ioannou and Mauro Overend.

Circularity in the Built Environment Graduation Awards

Samanwita Ghosh is one of the five winners of the Circularity in the Built Environment Graduation Awards 2022-2023. With her graduation project she was elected winner in the category 'Materials & Components (Tillmann Klein Award)'.

The Circularity in the Built Environment Graduation Awards recognise the contribution BK graduation students make to the transition toward a circular built environment. These annual awards aim to stimulate research and innovation in the field of circularity in the built environment.

The Circularity in the Built Environment Graduation Awards is an initiative of the Circular Built Environment Hub of the Faculty of Architecture and the Built Environment, TU Delft.

Read also the stories of the other four winners.

Samanwita Ghosh

Winner Circularity in the Built Environment Graduation Awards 2022-2023 in the category 'Materials & Components (Tillmann Klein Award)'.