Agriculture worldwide contributes one quarter of annual greenhouse gas emissions. Therefore, the global food system needs to greatly reduce its climate impact. With urban vertical farming not only can food be produced closer to consumers, but the heat produced by vertical farms can be captured and reused in urban energy grids, thus contributing to a circular built environment. Vertical farms can also benefit from the carbon dioxide produced by building occupants and rainwater harvesting from rooftops. Researcher Andy Jenkins explains how we can make this type of agriculture a solution for the future.

When considering the full value chain from production through to waste, agriculture worldwide contributes one quarter of annual greenhouse gas emissions. The global food system, therefore, needs to greatly reduce its climate impact if the world is to move towards a zero-carbon future by 2050. Vertical farming is seen as a possible solution, but the practice is still very much in its infancy. Vertical farms aim to address the climate impact of agriculture by stacking food production in sealed boxes with the use of artificial lighting and ventilation systems. This method of farming is water efficient, nutrient efficient, uses very little land, is highly productive, and typically does not require the use of herbicides or pesticides.

“Vertical farming requires a lot of energy to grow food, which is restricting it from achieving its full potential”, says researcher Andy Jenkins. “Currently, the carbon footprint of the practice can be many times greater than greenhouse horticulture and open field farming due to the energy demands of multi-spectra LED lamps, mechanical ventilation, and cooling systems used to create carefully controlled and optimised growing conditions.” Together with lighting specialists, breeding companies, growers, horticulture technology companies, architects, and food suppliers, Andy strives to make this type of vertical agriculture more energy efficient in the future by leveraging circular principles to share and reuse resources such as water, heat, and CO2.

Impressive multiple growing layers

Before Andy joined TU Delft, he had prior experience with food production in urban environments. He received his PhD at Queen’s University of Belfast in architecture and urban agriculture, which manifested in the design, construction, and operation of a multi-storey soilless food system, that used fish to grow food within a disused warehouse in England. Now, his focus has shifted to researching the role of vertical farms within buildings and cities. Describing his own experiences visiting vertical farms, Andy says: “When you step into a vertical farm for the first time, it is difficult not to be enamored by the blue, red, and white led lights, along with the produce that looks healthy and vibrant. The environment is comfortable, there is a pleasant breeze, and you can hear the trickling of water as nutrients flow around the system. As you look up, the multiple growing layers are impressive, and it is amazing to see just how much food can be grown in such a small footprint.”

He continues: “The vertical farming industry is now in a position where the technology is proven and the financial implications are clearer, which makes vertical farms more investible. As a result, we are now seeing a departure from small experimental farms to large, big-box farms that can occupy half a football field and be 15 to 20 growing layers in height.” As these farms grow, both in size and number, there is a growing interest for them to be sustainable. “We still have a lot to learn about how to make this a reality, but I believe that the symbiotic integration of vertical farms in the built environment, including circular use of water, heat and CO2, has the potential to contribute to this.”

Leveraging symbiotic relationships

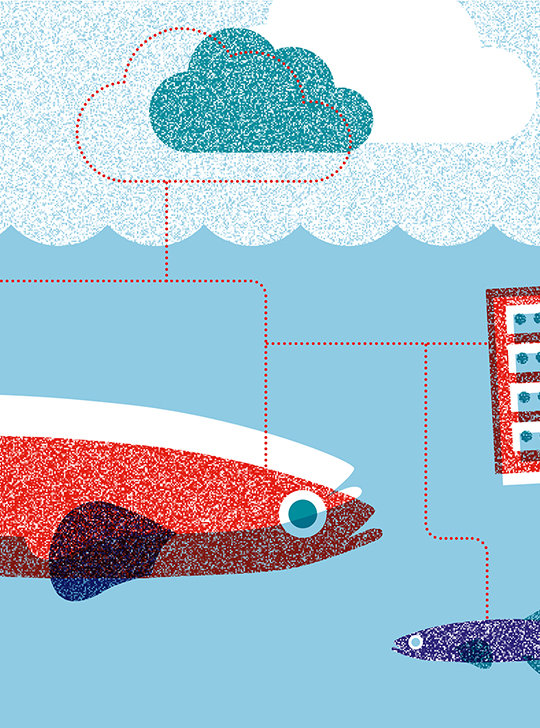

Andy’s goal is to reduce the energy use of vertical farms per kilogram of produce to the same as that of greenhouse horticulture, or better. “We explore ways in which the energy use of vertical farms can be reduced by first optimising climate control systems and then exploring their integration in buildings and cities to capture, share, and reuse resources such as carbon dioxide, heat, rainwater, food, and nutrients. This includes integrating vertical farms with a building’s electricity, heat, and resource systems as well as the broader integration with urban heat grids and micro electricity grids, making them a constituent component of future circular resource systems in cities. It is hoped that by leveraging symbiotic relationships between vertical farming and the built environment, the reduction in energy use of vertical farms can be fast-tracked, without relying solely on the technical advancements of equipment within the farm.”

The symbiotic integration of vertical farms in the built environment has the potential to greatly decrease the environmental impact of the practice.

When speaking about the research, Andy mentions the areas of interest he is currently working on. “My current focus is to develop a simple tool to help architects and vertical farmers understand the energy balance of vertical farms when integrated with buildings. This will be based on building programme and the total growing area of the vertical farm, with a specific focus on heat capture and reuse. Alongside colleagues at TU Delft, we are also working hard to complete a carbon footprint analysis of vertical farming in comparison to greenhouse horticulture and open-field farming. These findings can then be used as a baseline to determine the carbon savings of different design strategies for the vertical farm and its integration within buildings and cities.”

Resource synergies, rather than direct energy savings

Andy Jenkins is optimistic that the energy use of vertical farming can be reduced to that of greenhouse horticulture but stresses that this might not necessarily be at the farm gate. “I expect that a large proportion of energy savings will be achieved through resource synergies, rather than direct energy savings at the farm. One of the areas that shows the most promise is the capture and reuse of heat generated by a vertical farm. Approximately 50 percent of the energy used by LED lighting is converted into heat, which needs to be extracted to maintain optimum growing conditions. I do not expect that our research will deliver a huge reduction in the heat produced by vertical farms, as this is determined primarily by LED technologies, although some small gains may be achieved. Instead, the design strategies proposed will focus on capturing as much of this heat as possible to reuse it in neighborhood heat grids to reduce the energy use of host buildings and adjacent buildings alike. It could be the case that vertical farms can only reduce their climate impacts significantly by being located within, or close to, cities, due to the immediate access to other resource flows. This could include vertical farms in domestic settings, rooftop, atrium or basement vertical farms in larger buildings, and large-scale peri-urban vertical farms on the periphery of cities.”

Vertical farming in the future

When discussing the future of vertical farming in cities, Andy summarises his thoughts as follows: “Vertical farms can be constructed much closer to where demands are highest, which can greatly reduce the food miles of some foods. Consequently, these crops do not need to be frozen or packaged as they are being sold quickly over short distances, which not only saves energy but can lead to improvements in nutrition by creating short supply chains. The wide-spread adoption of vertical farms in cities can create jobs and reconnect citizens with farmers and food production, and the heat produced by vertical farms can be captured and reused in urban energy grids, making the farms part of a circular built environment. For me, there is no question that vertical farming is here to stay.”

Sky High – Project C2 is part of the NWO Sky High research programme, which aims to improve the productivity, predictability, and replicability of vertical farming.

Andy Jenkins works alongside TU Delft colleagues Tess Blom and Andy van den Dobbelsteen.