An unconventional tube that could save lives

‘We’re achieving a fantasy: a tube with completely unconventional mechanical properties. This could help prevent complications in thoracic endovascular aortic repair.’

When you apply a force on a non-rigid hollow tube, it will deform in a certain way. From everyday experiences, we all have a feeling for how a tubular structure buckles when it is compressed. By making the tube more rigid, the risk of deformations and buckling can be reduced. But what if you need a tube that is both rigid and flexible: one that can be deformed only in the radial direction, but not in any other direction? One that does not buckle or lose its circular profile? No natural material or simple design can live up to those demands. Nonetheless, Dr. Farbod Alijani (Dept. of Precision and Microsystem Engineering), Dr. Dimitra Dodou (Dept. of BioMechanical Engineering) and their co-workers took on the challenge to design such a system. There is no room for error since the tubes are eventually meant to save the lives of patients with an acute thoracic aortic aneurysm. The researchers’ cohesion project, entitled ‘Compliant Shells for Thoracic Endovascular Aortic Aneurysm Repair,’ should provide a first proof-of-principle that an origami-like folded structure can do the trick.

Shell structures for healthcare

Shell structures are thin, curved and continuous structures, well-known from nature and everyday objects. In general, they are light-weight structures and especially suited for building purposes and for industrial applications, such as oil pipes and reactor vessels. They also have a structural form that displays complex behaviour and is difficult to analyse. Before moving to TU Delft, Alijani focused on theoretically and numerically modelling the mechanical properties of such shell structures. ‘What made it attractive for me to move to TU Delft was that I would be able to team up with experts in shell design.’

Collaboration to achieve societal impact

Moreover, Alijani always wanted to apply his expertise to an area with the most tangible impact on people’s lives: healthcare. ‘I’m not scared of blood and want to achieve real societal impact. My group leader at TU Delft introduced me to surgeons at the Leiden University Medical Centre, with whom I discussed our design capabilities and their needs.’ Applying his engineering expertise to the realm of medical devices meant Alijani would need the support of experts in the biomedical field. ‘Luckily, our faculty has an outstanding biomechanical engineering department. So, I asked Dodou from that department to join the project. Together we supervise post-doctoral researcher Dr. Guissepe Radaelli. He really dived into the topic, going as far as looking over the shoulders of doctors performing surgery.’

‘In the Netherlands, aortic aneurysm is still in the top 25 main causes of death’

Preventing an aneurysm

The topic Alijani identified in his discussions with the surgeons in Leiden concerns patients with an aneurysm in the aorta, the body’s main blood vessel. Such an aneurysm is the culmination of a process in which the structural properties of the aortic wall deteriorate over time, causing the aorta to bulge or balloon. Eventually, the artery will rupture, often with fatal consequences. A way to prevent an aneurysm rupture when the artery is already affected, one that does not require open surgery, is by applying a so-called stent-graft inside the diseased artery using a minimally invasive surgical procedure. The stent-graft is essentially a tube that protects the aneurysm from rupturing. The minimally invasive nature of the procedure requires the tube to be made of a very flexible woven polyester material surrounded by a stainless-steel mesh, known as a stent. This frame can be squeezed into a thinner delivery catheter which is inserted into the aorta. When in place, the stent-graft expands, taking over the role of the affected part of the aorta and relieving the pressure on the aneurysm.

Complications

While the stent-graft is a proven technique, there can be complications profoundly affecting patients. Alijani explains: ‘The two ends of the stent-graft are especially crucial for the success of the procedure. They need to expand in such a way that they clamp themselves to the nearby healthy aorta wall in order for the stent-graft to remain fixed where it is needed most: inside the aneurysm. However, the natural micromotion of the aorta due to the beating of the heart causes unwanted shifting of the stent-graft. Metal hooks and barb-like elements are typically employed at the outer ends of the metal mesh to fixate it even better. Unfortunately, in up to 25% of cases, they cause irritation or even leakage of blood flow towards the aneurysm.’ From an engineering point of view, this is a seemingly impossible situation: the stent-graft should be stiff to keep its shape and withstand micromotion of the aorta, yet this stiffness irritates the tissue at the end areas where the stent-graft is fixated to the aorta wall.

‘From an engineering point of view, this is a seemingly impossible situation: the stent-graft needs to be rigid and flexible at the same time.’

Revolutionary design

Revolutionary design

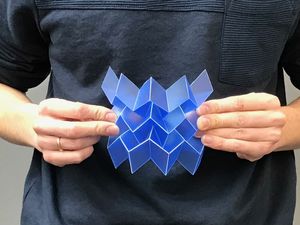

Alijani gladly took on the challenge. His team set out to create a shell-like structure unlike any other found in nature; a so-called metamaterial that is soft in the radial direction (meaning that it can move along with the micromotion of the aorta), yet stiff in all other directions (meaning that it does not buckle and constantly maintains an outward force with which the stent-graft end-points clamp themselves to the aorta wall). How do you make such an impossible material? Radaelli found the answer in kirigami, a folding technique similar to origami. Indeed, the demonstrator model on Alijani’s desk, an oversized building block of what could one day replace the metal mesh keeping stent-grafts in place, looks a lot like origami. Yet, surprisingly, it does the trick, allowing stretching along its length and refusing to bend in any other direction. On the basis of this structural design, Radaelli performed numerical simulations with very promising results. Alijani: ‘After years working on conventional shell structures, it is very rewarding to create a structure with properties that are completely unconventional. This design could be revolutionary!’

‘After years working on conventional shell structures, it is very rewarding to create a structure with properties that are completely unconventional. This design could be revolutionary!’

Pilot data for a large-scale programme

For Alijani, the cohesion project is part of a larger plan. ‘My proposal outlined a large-scale programme for which the cohesion project, supported by funds from the TU Delft Health Initiative, would provide the pilot data.’ After the first results, the system needs to be scaled up, and other issues such as long-term stability need to be addressed. Will the system buckle under certain pressures? What role do fluid-structure interactions play? Dodou also has a further idea to improve the fixation of the stent-graft to the aorta: a tissue adhesive -or glue- that is already being used for cardiovascular surgery. Eventually, the team should start thinking about practical manufacturing. Alijani: ‘This will take at least 10 years. At this point, our project has passed the toddler level but is still in its infancy.’

‘The cohesion project provides the pilot data for a large-scale programme that will take at least 10 years.’

Dr. Farbod Alijani (Dept. of Precision and Microsystems Engineering) received his PhD in 2011 from Tehran Polytechnic University, specialising in non-linear vibrations and the stability of shell-type structures. Next, he worked as postdoctoral scholar at McGill University in Canada and as research associate at the University of Parma in Italy. He aims to address open problems in non-linear dynamics and fluid-structure interaction at macro, micro and nanoscale with innovations in experimental, theoretical and numerical investigation.

Dr. Dimitra Dodou (Dept. of BioMechanical Engineering) received her PhD in 2006 (cum laude). After a postdoctoral stay at Max Planck Institute for Metal Research, she was awarded an NWO-Veni grant (2009) to investigate the role of morphology of the attachment apparatuses of echinoderms in underwater adhesion and emulate these for soft tissue adhesion. She became assistant professor in 2008 and associate professor in 2017. Her present research interests encompass the development of adhesives and adhesive methods that allow for the effective manipulation of soft and wet biological tissue.

ME Cohesionprojects

The cohesion projects were launched in 2014 based on an idea by Dean Theun Baller, the aim of which is to encourage interdisciplinary cooperation within the faculty. A good engineer, after all, is inherently good at working with others, and most innovations take place on the cutting edge of disciplines. The cohesion projects give young researchers the opportunity to ask for funding for projects, on the condition that they work together with colleagues within the faculty and outside their own discipline. Mechanical Engineering, Maritime Technology and Materials Science have proven to be extremely suitable for unexpected cross-overs with surprising outcomes.