Sustainable medical instruments for developing countries

Sterilisation has been the most common method of birth control for women in India since the 1970s. According to the country’s national authorities, India needs to keep population growth under control, otherwise it risks overtaking China, currently the most populous country in the world, by 2028. Though there is severe criticism of this sterilisation policy (after all, there are less drastic ways of getting people to have fewer children, and on top of that India’s birth rate is already decreasing as a result of increased prosperity), more than one in three women are being sterilised at the moment. Often with fatal consequences.

Operations take place in what are sometimes dubious private clinics. Women often undergo an open operation in these places via a large incision, so it takes a long time for them to recover. Moreover, there is a serious risk of infection because the environment is often not sterile

Tim Horeman, assistant professor of sustainable surgery in the field of biomedical technology at the ME faculty and co-founder of four techno-starters.

‘That’s why I want to develop instruments to perform laparoscopic sterilisations in India.’ With laparoscopy, otherwise known to as minimally invasive surgery, the doctor makes a small incision in the belly, then inserts an instrument with a camera into the body and places, in this case, a clip around the oviduct. ‘Operating like this enables the doctor to cut through less tissue, so women are mobile again within a few hours.’

Recently, Horeman and his colleague Jenny Dankelman, who is professor of minimally invasive surgery and intervention techniques at the Department of BioMechanical Engineering, were awarded a significant grant from NWO/ZonMw for their initiative. Their research focuses on the development of affordable and innovative instruments for minimally invasive surgery, so that hospitals in developing countries can also perform this kind of surgery. Not only in hospitals, but also outside the sterile operating room. This would make sterilisation cheaper, but also safer and easier to perform. Dankelman and Horeman are working together with Prashant Jha from the School of International Biodesign of AIIMS and IIT Delhi and his Indian partners from the Surgery Department and the Community Medicine Department of AIIMS Delhi in this research.

As for Horeman, he prefers to be in his Minimally Invasive Surgery and Interventional Techniques Lab (MISIT), which is situated on the ground floor of ME. There, he and his colleagues develop a wide variety of instruments for minimally invasive surgery. The biomedical engineer shows us the gold standard for laparoscopic graspers (8 millimetres) currently on the market, which is operated by surgical robots. ‘This instrument is driven by four motors that can turn the instrument in two lateral directions and make them open and close,’ says Horeman, who took apart the instrument and counted 72 parts, such as pins, wheels, tubes, springs and cables. ‘These instruments are usually thrown out after a few operations. That’s because they can’t be disassembled and so cannot be cleaned,’ he says. ‘On top of that, operation robots are being increasingly used: every year there are 55 additional robots in circulation. It may sound ambitious, but scientists expect 35 per cent of all laparoscopic operations to be performed by robots by 2025 (Forbes). If we are still using the same device technology in that year, then our landfills will be cluttered with 10 million used instruments a year.’

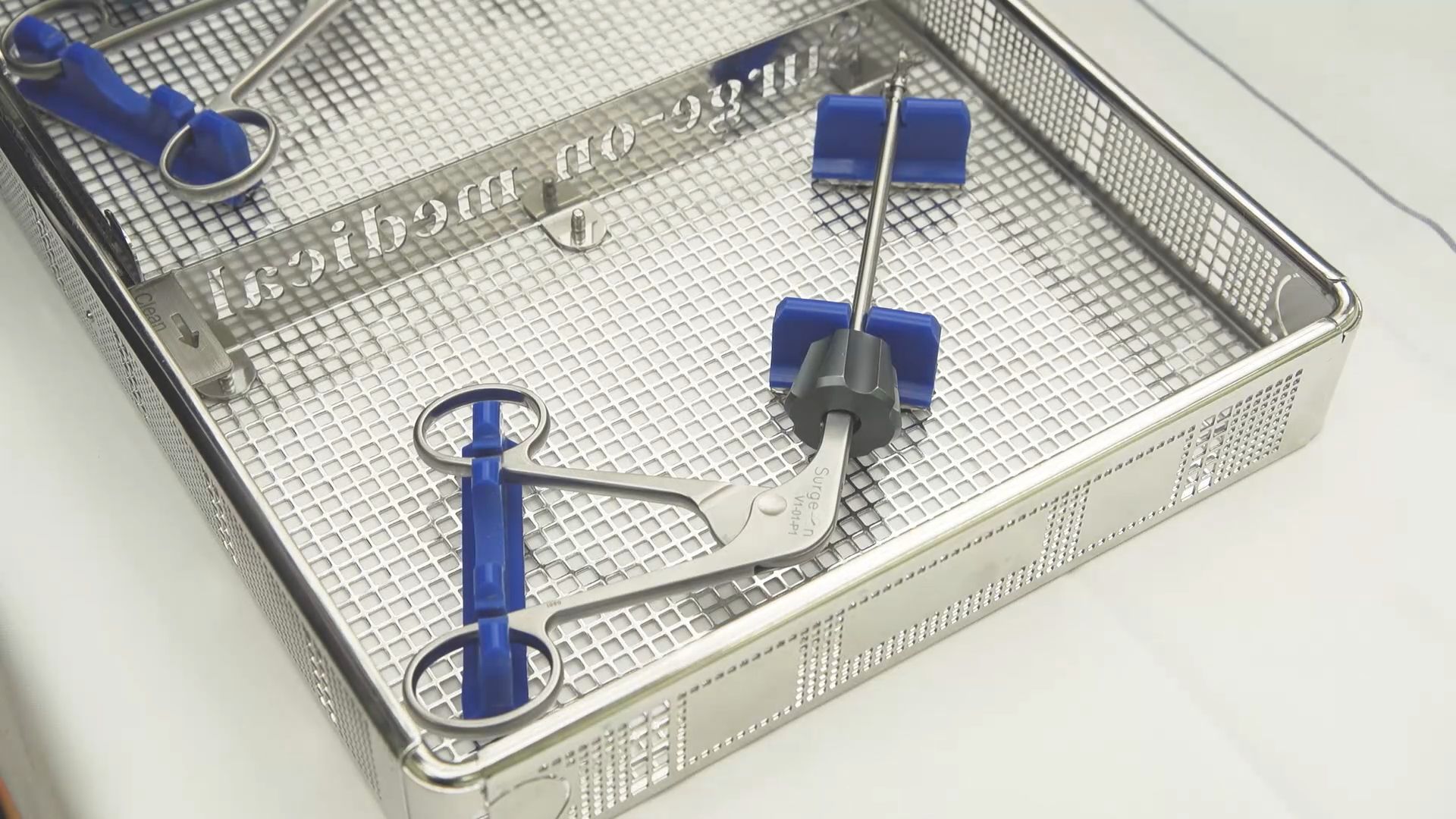

Horeman has come up with a more sustainable version of the standard grasper. ‘There are three layers of tubes in it,’ says the researcher, who immediately shows us how to disassemble the new grasper, which is 5 millimetres thinner than the existing one and also contains 70 per cent fewer parts. ‘You can completely pull it apart so all that’s left are the tubes and tip of the instrument, which you can open up and then clean using the standard sterilisation processes in the hospital.’ The fact that the grasper can be reused generates huge savings for the hospital, which makes the minimally invasive operations affordable for countries such as India. ‘The instruments that you have to keep throwing away during robot surgery cost an additional 4,000 to 5,000 euros per procedure, on top of what laparoscopy already costs. So this new technique, which is now being further developed under license by the company Surge-On Medical, is not only making the medical world more sustainable, but also more accessible for surgeons.’

But that’s not the only advantage of the new grasper. Doctors can attach a grip that allows them to rotate the shafts with two wheels and a trigger. That’s not possible with the current designs of these instruments, because they always have to be operated by a surgical robot. Now that grasper can be used in areas where there is no surgical robot. ‘Essentially I am potentially solving both the financial and functional problems of the standard robot instrument,’ says Horeman, who isn’t sure yet whether his new manually operated instrument will really be able to compete with the robot-operated version. ‘No scientific research has been conducted on that yet. But we have compared the different instruments in a training environment and that looked very promising.’

According to the biomedical engineer, a major scientific challenge still lies ahead. He now wants to construct the steel components in the instrument in such a way that they can conduct electricity to close tissue. ‘When you operate, you often have to cut tissue in half. That subsequently starts to bleed. To stop that, you could put a clamp on it that has a current running through it. That would enable you to close the vessels by burning them,’ he says. To achieve that, Horeman is going to work with physicists who have knowledge about fusing/vaporising materials with different properties.

If we can manage to do that, then we will not only have made huge mechanical progress, but also progress at the level of components. Then you’re working on a new generation of instrument construction. That’s when the fun really starts.

What would be perfect according to Horeman is if he could make an instrument for India that can be disassembled and sterilised, which has exactly the same functionality as the existing one, without the need for a robot or complicated cleaning procedures. He has even come up with a solution, together with Jenny and the company MediShield, for hospitals that lack operating rooms: the mini-clean room, a modular, dividable screen that shields the instruments and wound at all times from the environment and which can easily be moved and set up in rural areas in less developed countries. Moreover, he no longer wants to have to rely on experts to maintain the parts of a robot or instrument. ‘That’s not compatible with sustainable surgery. I want people to be able to maintain, clean and assemble things themselves on-site,’ says Horeman. ‘So you have to train people on-site: technology is never the only solution.’

Sometimes the Delft researcher is criticised for not spending enough of his time being scientific as a result of his sometimes pragmatic output. Horeman usually dismisses these comments. ‘There are 15 patents on my innovative technologies, they’re always based on a social and theoretical problem, and we write detailed scientific papers about them in leading academic journals,’ he says. ‘But the most important thing is that I ultimately make the world a better place, and that the real peers, i.e. the end users, experience the added value of my science.’