Innovation from the lab into the real world

Nima Tolou, a researcher and entrepreneur at Delft, is very proud of a new development in the core of mechanical watches. In a close cooperation with the LVMH Watch Division (TAG Heuer/Zenith) and Flexous, a start-up from TU Delft that he co-founded with physicist and entrepreneur Oleg Guziy, he used his expertise in compliant mechanisms and MEMS technology to co-develop a watch with a totally new time mechanism. Along with this, he’s working on another innovative device that converts vibrations into free energy.

‘For me, an innovation is not complete until the finding actually works in the real world. In other words, outside the lab,’ he emphasises. But the real world is often stubborn. Unexpected problems emerge that ruin even the most fabulous innovations. A great discovery can end up in the archives of science, carefully described in a paper or patent.

That’s very important but for Tolou not enough. ‘As a child I made my own toys. At school in Iran I regularly won awards for my creations. I’m a thinker, a designer, but definitely also a maker.’

Tolou is convinced that the developers themselves know and understand their technology better than anyone. ‘In case of the watch, we started all over many times. You don’t give up easily when you’re convinced that there’s a solution. The faith that it can work is a key aspect of the development.’

Flexible

The size of the control mechanisms in watches has been considerably miniaturised since Dutch scientist Christiaan Huygens invented the pendulum in 1675, but the principle hasn’t changed. The pendulum in the clock, or the spring drive in a watch, ensures that the hands always indicate the right time through a complex system consisting of many parts. But Tolou, who has a background in physics and mathematics, together with the LVMH Watch Division and Flexous, discovered an alternative.

Most mechanical systems consist of rigid structures, usually metals. Think of the wheels, pinions and bearings. Tolou and his research team specialise in micro mechanisms that contain flexible, elastic components, referred to as compliant micro mechanisms. In other words, matter that gives, bends, quivers or vibrates.

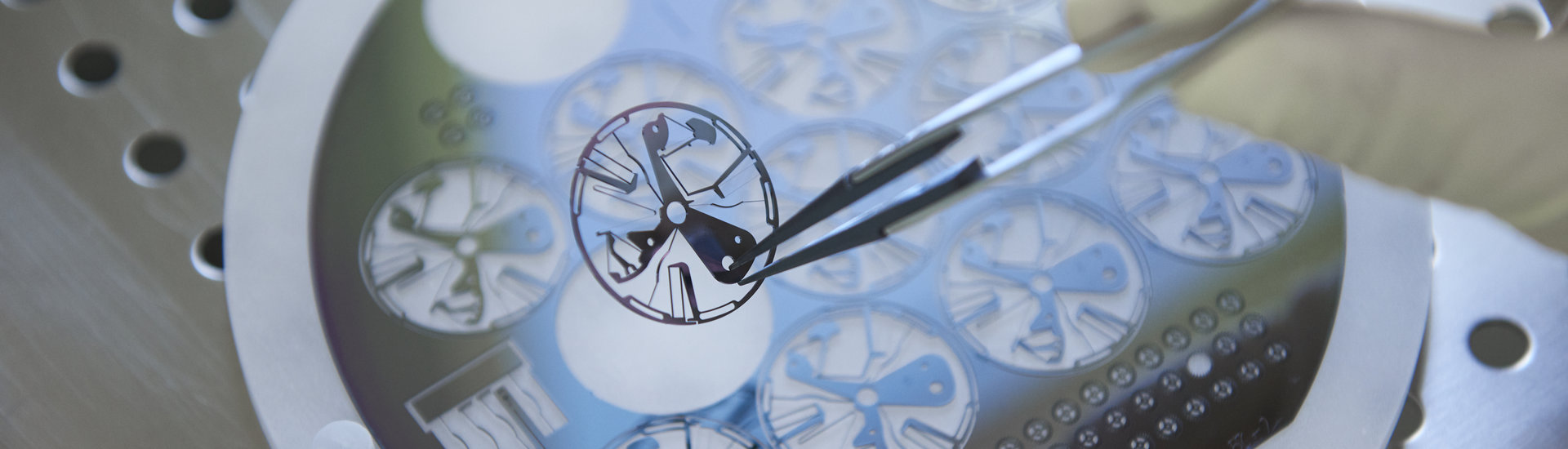

The team discovered that a single circular part with complexly shaped cut-outs can combine multiple essential functions that take more than 30 parts in a conventional watch. This new approach, along with smart use of the nonlinear nature of compliant mechanisms, lead to an innovative mechanical system that is more accurate, more precise and more energy efficient at the same time. The other advantage of this idea is that with high precision production techniques, this kind of watch mechanism can be etched from a single flat piece of silicon.

And it will be simpler, small, maintenance-free and robust. Tolou was convinced that you can apply these compliant micro mechanisms in a watch. Who dares to realize such a wild idea? Mechanical watch makers tend to fancy classical craftsmanship. After 3 years, the TU Delft team, Flexous and the LVMH Watch Division, managed to realise this. The product was introduced by LVMH to the market on 14 September 2017 under the name Zenith Defy Lab as “the world’s most accurate mechanical watch”.

A series of publications provided general knowledge about the accurate design of oscillators in compliant mechanisms and lead to the granting of two Best Paper awards at international conferences in France (MARSS) and the United States (ASME IDETC).

Free power

A second finding by the Delft researcher is about to be made public: an energy harvester. It’s a device that harvests energy when it vibrates after passing of a car, for example, or because it’s standing on a machine. The crux of the discovery, however, lies in the use of extremely small, flexible components that makes the device sensitive to low frequencies and irregular vibrations. ‘It’s about mass on specially shaped elastic material,’ Tolou says. ‘This mass starts to move as a result of vibrations, and we subsequently convert this movement into power.’

The prototype looks like a thick classic battery (size D). ‘But one that charges itself,’ Tolou says. The energy harvester can provide sensors with power and make it possible to send data. And these types of sensors are becoming increasingly prevalent. There are expected to be twenty billion of them in the world in just a few years’ time. ‘Nowadays we connect all devices to each other: the Internet of Things. Our environment is becoming increasingly interactive,’ Tolou says.

Sensors that derive their energy from vibrations don’t have a plug. Their battery lasts ‘forever’. That makes them considerably less expensive, particularly in hostile environments and places that are difficult to access where battery replacement is inconvenient or expensive.

Tolou’s energy harvesters are therefore useful for monitoring moving objects: sea containers, sheep in mountainous environments or a stolen bike. But they’re also useful for detecting forest fires or the sound of illegal chainsaws in the rainforest. You simply hang the sensor on a drooping branch. Most of all, Tolou hopes to make the world a little bit safer, more efficient and more productive . For example, sensors on railway tracks or train wheels that automatically warn you when a train is approaching. And many more sensors on industrial estates. ‘If sensors are inexpensive and can function independently, then you can attach them to every storage tank, pipe, pump and valve.’ Overheating will be signalled in good time and maintenance will be carried out based on measurements instead of annual cycles.

‘What’s more, you’re doing all this with energy that would otherwise be wasted,’ Tolou explains. Free and environmentally friendly electricity in other words. The amount of power generated by his energy harvester is limited to a maximum of 10-20 milliwatts, however. ‘Not enough to charge your mobile phone, in any case. For that you would need to fill your backpack with harvesters. Which isn’t very practical, of course.’

Thanks to the unstoppable rise of sensors, harvesting energy from our environment has become a hot field of research with a great deal of competition. So what is it that makes Tolou’s discovery so promising? ‘Our energy harvester can convert fast and slow vibrations into power. In many other systems, the vibrations have to be within a specific range. But it makes no difference with our system whether you are cycling quickly or slowly over cobblestones.’ Also in this case the breakthrough was generated because of the combination of thorough knowledge (the Veni-award of Tolou) and his drive to turn innovations into products.

Gap

Tolou is working on new products with the spin-off company Flexous that he co-founded in early 2014 with physicist and entrepreneur Oleg Guziy. Tolou is technical advisor, Guziy CEO. The division that focuses on marketing the motion energy harvester has been named Kinergizer. “Flexous bridges the gap between academy and production. If you introduce your idea to the world by means of a patent license, it will take years before you actually have a product. If you work on the development as an inventor, as a fundamental researcher, then it will happen more quickly, in two to three years’ time. But most of all, I want to be involved in it all, contribute by thinking and acting myself. The process is at least as exciting as the end result.’

Tolou certainly proved that with the recent products. What will his next project be? ‘I’m focusing mainly on research on autonomous systems: self-sufficient electronics. Devices that observe autonomously and subsequently respond to their environment. And they can do that thanks to an energy harvester.

Nima Tolou (1982) studied applied mechanical design in Iran. He has been working at TU Delft since 2008, first as a PhD student, and now as a university lecturer. ‘I wanted to continue doing research, but the opportunities were limited in Iran.’ Tolou searched for a reputable university in the area of applied research. He actively seeks partners in the business sector to convert findings and research results into products with his own team.

![[Translate to English:] Nima Tolou](https://filelist.tudelft.nl/me/Onderzoek/Check%20out%20our%20Science/Headerafb/Picture%20Nima%20portret.jpg)