Max-SCORE: Maximizing SCrap in COnverter REfinging

Shifting the limits of scrap usage in steelmaking converters to minimize CO2 emissions

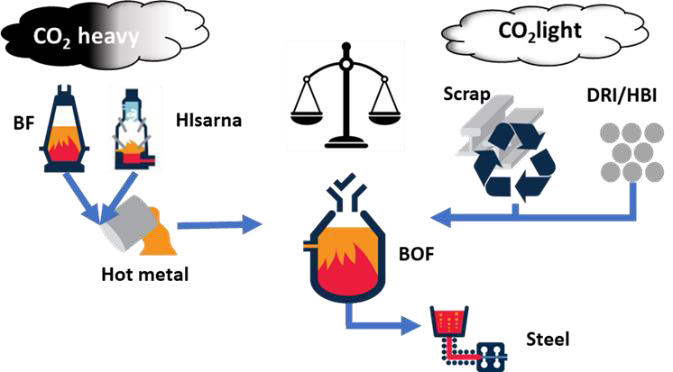

With maximized charging of high and especially low quality steel scrap, together with HIsarna ironmaking, the steel company aims to substantially reduce the primary raw material consumption and increase production of high quality products from scrap. The project goals are set to understand the dynamic melting and refining behavior of scrap in complex shapes and sizes together with BF and HIsarna hot metal; to develop a DEM-CFD based scrap melting and refining model for the converter process, and to validate with plant data and provide the theoretical and practical guidance to reach the above goals. The outcome of the project will be used to widen the raw materials and operating window of scrap addition to the state-of-the-art oxygen steelmaking converters; to maximize the usage of lower quality scrap from the scrap market, without compromising the steel quality and process stability; to implement optimized scrap charging strategies to the converter operation; and finally to increase the recyclability of the lower quality scraps and further reduce CO2 emissions in the steelmaking process.