Flexible wings

Watch a bird as it lands: the wings are turned back, the feathers correcting for gusts of wind. Aircraft wings are stiff and rigid and actually only optimised for horizontal flight at a height of 10 km.

In 2006, head of research Dr Roeland De Breuker (Faculty of Aerospace Engineering) was awarded his PhD based on the idea of flexible aircraft wings. Since then, the Morphing Wings research line has continued as an option for making flying more sustainable. Flexible wings are smoother than today’s wings with their flaps and slits. They change shape when the fuel consumption during flight changes the weight distribution, and they reduce the forces on the attachment to the fuselage so that the construction can become lighter. De Breuker estimates that flexible wings could save up to 10% fuel.

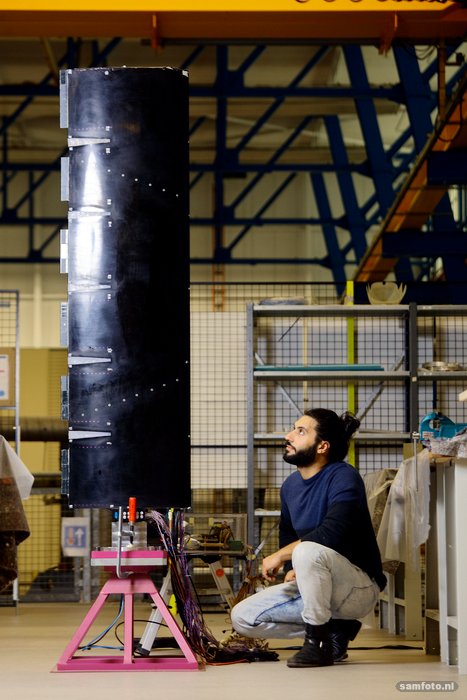

Together with two fellow PhD students, Nakash Nazeer and Vincent Stuber, Tigran Mkhoyan developed the SmartX-Alpha that uses sensors, glass fibres and servomotors to respond to gusts of wind. This summer, Mkhoyan built its successor in Germany: SmartX-Neo. When the mould was opened, the atmosphere was very tense. How would it turn out? In the days that followed, sensors and servos were added and connected using dozens of labelled cables and glass fibres.

According to Mkhoyan, the main differences from its predecessor are the lighter structure, servos that are three times faster and almost twice as many flaps (ten instead of six). Although the way the flaps connect to the rear of the aircraft is less smooth, that makes it respond more rapidly. The next step, SmartX-Beta, will be a medium-sized drone (span width 10 m) featuring two morphing wings as a demonstration platform. It is expected to take three years.