Sensor techniques that determine a structure’s health condition are often expensive, complex, energy-intensive, and unreliable for long-time operation. To simplify the process, Assistant Professor Mohammad Fotouhi, specialised in Structural Health Monitoring, is innovating cost-effective coating materials designed to change colour as an early warning system, alerting asset owners well in advance of potential failures. This smart and sustainable technique is already advanced enough to be used, but Fotouhi continues to perfect its sensor function in his quest to convince industries to adopt innovative materials.

What do opals and chameleons have in common? Both the gemstone and the animal’s skin can change colour. External stimuli such as heat (in opal) and a dangerous condition (in chameleons) cause the structure to modify the way light bounces off the surface resulting in a change of colour. Inspired by this natural phenomenon, Fotouhi hit upon an idea for an innovative technology: sensor material that changes colour to indicate critical damage or remaining lifetime of structures.

Fotouhi’s Eureka moment came when he was researching composite materials at the University of Bristol. “The team and I were working on the development of a new composite material consisting of carbon fibres. When we tested it, we found that not only was it extremely strong, but it changed the colour when put under mechanical stress. That triggered more research into this property and its applications, for instance for use as a visually readable sensor.”

Determining the condition of a structure

Sensors play an important role in Fotouhi’s work. Part of his research is aimed at finding the best way of monitoring the condition of a structure. “Structural load, static and cyclic forces can affect the condition of a structure. It makes it unable to operate, damage or even break it. Monitoring the state of a structure will tell you when maintenance, or some other intervention such as repair, is needed before it is too late. In some cases, lives may depend on it, think of a damaged plane wing, or a bridge that is about to collapse.”

Current technologies are costly and energy-intensive

Current critical structures such as bridges and wind turbines can fail suddenly without any visible warning. An example is the collapse of a bridge in Italy in 2018 that killed 43 people. Current monitoring techniques include the use of several diagnostic tools, which determine critical conditions, such as vibration-based, acoustic emission-based, and ultrasonic-based sensors, Fotouhi says.

“Together, the data gathered by these tools provide a good picture of the status of the structure. But there are downsides, such as cost, high energy use and unreliable sensing in the long term. Sensors, for example, have batteries and cables. You also need space to store and process the data. Apart from that, inspections of some structures can be very time-consuming and complex, requiring skilled inspectors having to take several samples for analysis.”

The power of simplicity

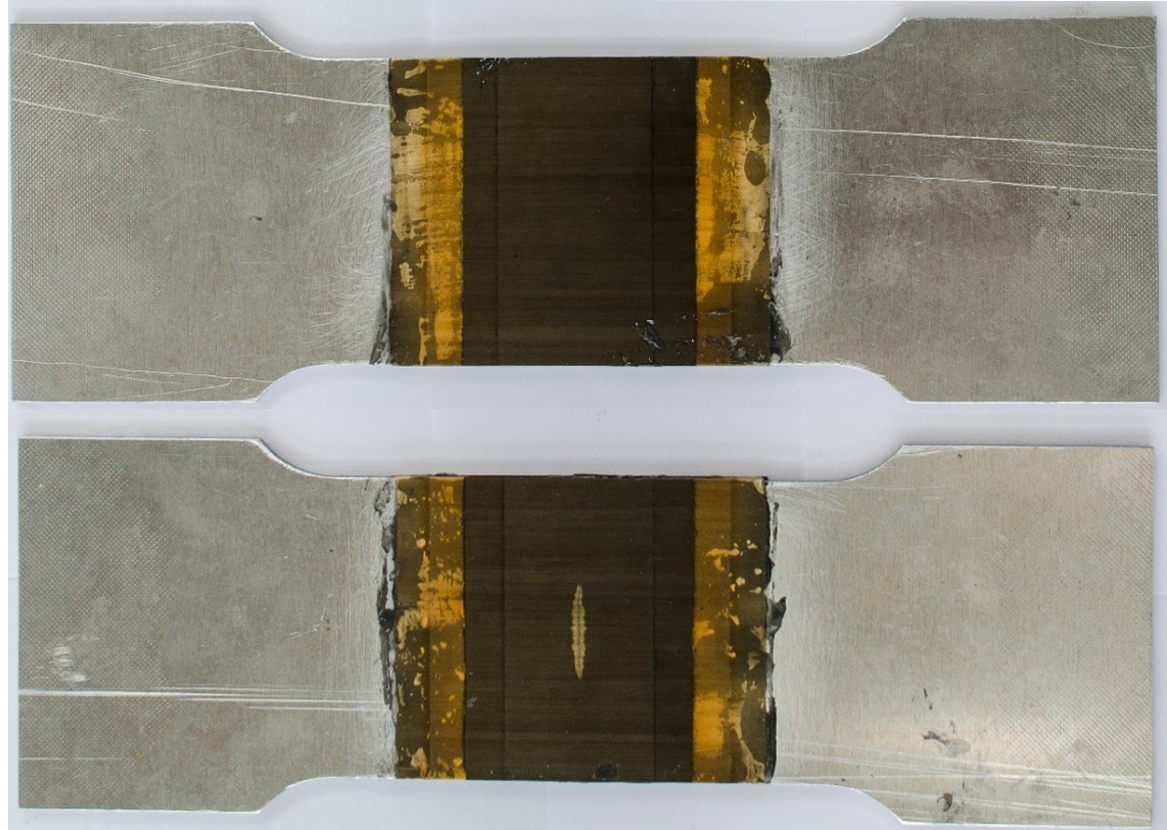

The material developed by Fotouhi gets around all of these problems because the sensor function is incorporated into the composite material itself. “The outside layer of the material consists of a thin-ply carbon fibre and glass,” he explains. “A critical condition caused by a high structural load, for instance, manifests in patterns with colour differences. The lighter the load, the darker the colour.

Fotouhi is particularly fascinated by the simplicity of the technology. ”I grew up in the countryside. We had little money and we had to rely on ourselves. It taught me to be creative at a young age and think of simple solutions. Many of today’s technologies are smart and handy but expensive and complex at the same time, I want to show that problems can also be solved using relatively simple and cheap techniques.”

The sensor material changing colour due to overload and crack growth

Detecting bird strike in aircraft panels

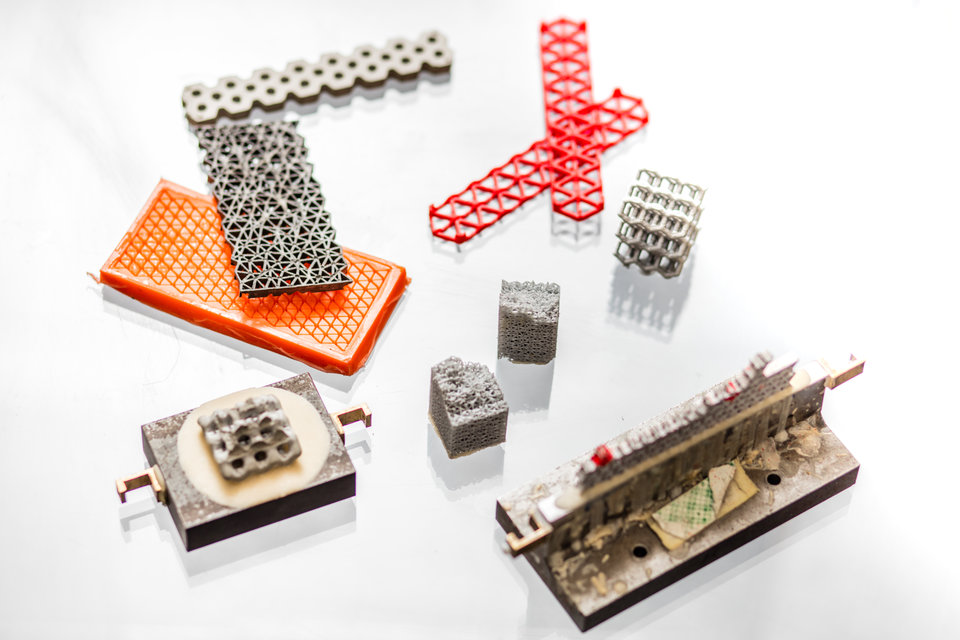

Fotouhi and his colleagues tested the sensor material using simulations and experiments. “We dropped a weight on the composite panels from different heights to simulate the impact of bird strike in aircraft panels. This often results in internal hidden damage that cannot be seen with the naked eye. But if you coat the plane with the sensor material the impact immediately shows up in visually readable colour differences on the surface.”

Building industry has an innovation challenge

The building industry could be an even more important market for the material than aviation. New sustainable materials and solutions exist, but are they reliable enough for the industry? That’s why introducing innovative products for building can be “extremely difficult” according to Fotouhi, as emerging materials are not proven to meet the safety standards. “You really have to show that a new material will be reliable and last for a very long time. Careful monitoring may help convince the sector to adopt more sustainable and innovative materials. The fact that industries are helping us to develop the sensor material is an enormous boost.”

Sensor material can be smarter still

Meanwhile, Fotouhi is working to improve the sensor material, including the effect of several coatings. “We are hoping this will give the material a kind of simple visually readable memory, a way of distinguishing the phases that the material has gone through. That could provide data about instances of a certain structural load on the structure and when they happened. It's another example of how a relatively simple and cheap solution can make expensive and complex technology obsolete.”