Picture an overcrowded platform at Rotterdam central station on a Monday morning. An overhead line on the train link Rotterdam-The Hague has snapped and there are no trains. Chaos reigns in the Randstad. Evert van Veldhuizen and Jan Moraal are experts in the area of pantograph-catenary interaction and if it’s up to them, in the future, a failing overhead line will no longer get the headline news.

The pantograph and the overhead line, or catenary, form a solid team: together they provide the energy the train needs to move. How is it done? The pantograph takes the electricity from the overhead line and feeds it to the train. But wear and tear caused by the prolonged friction between the pantograph and the overhead line weakens the overhead line and can cause it to snap. ‘If an overhead line breaks it comes down, coiling like strand of spaghetti,’ Moraal says. Repairs can take a long time and may affect the adjacent track as well. That means long delays and angry travellers. That is why railway operator ProRail asked Van Veldhuizen and Moraal to find a way of preventing overhead lines from breaking. One of the things they came up with was the rolling pantograph.

Rolling

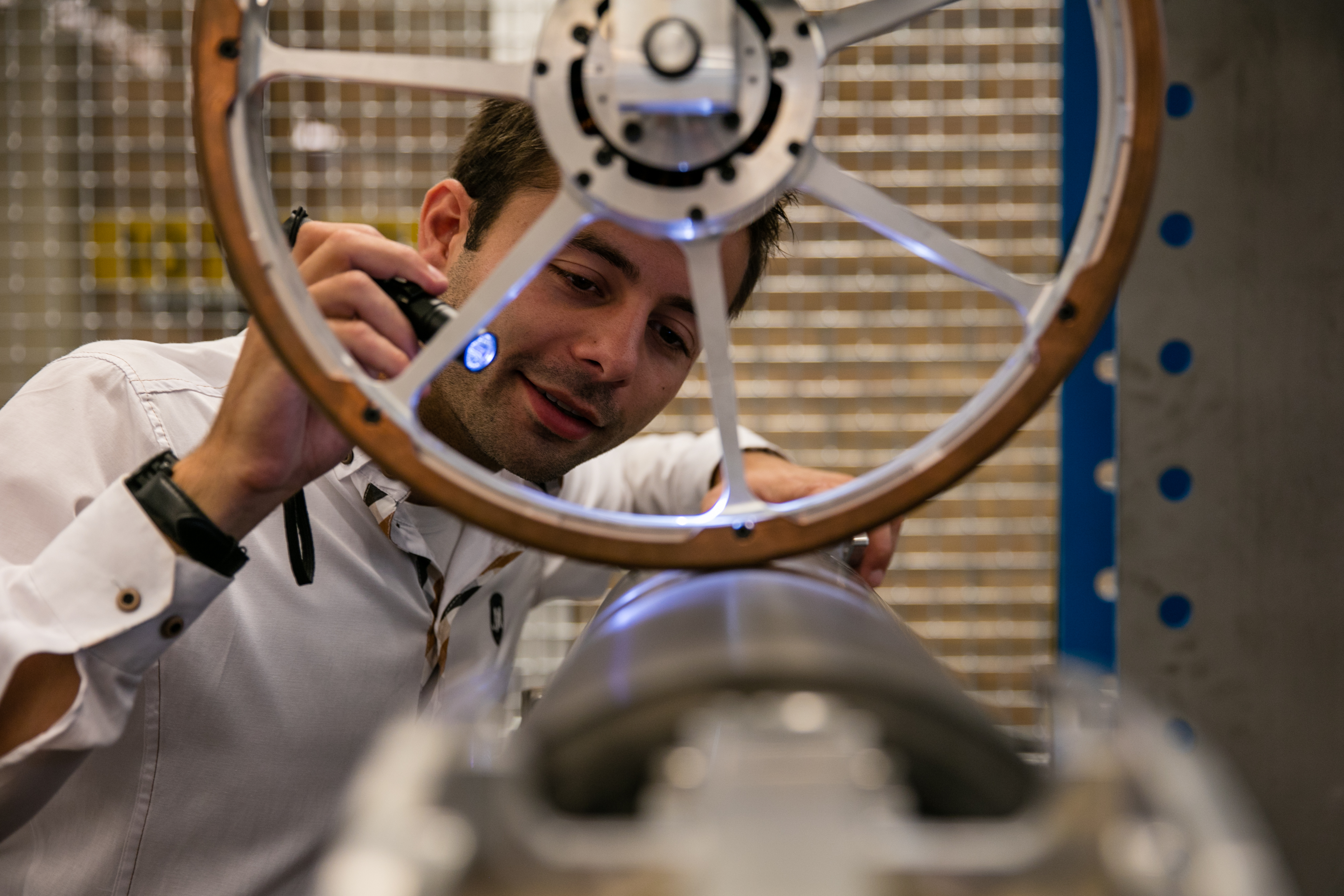

‘Our newly designed pantograph doesn’t slide, it rolls,’ Van Veldhuizen explains. ‘Rolling produces less resistance and that means less wear and tear. But looking at the behaviour of the pantograph is not enough. At the Stevin lab of the faculty of Civil Engineering and Geosciences we are looking at the optimum way a pantograph can transmit energy to a train. That is a challenge. The electric current is transported from the line to the roller which in its turn transmits it to the train. The supply of energy has to be constant, without interruption. The contact between the pantograph and the line becomes more critical when the train picks up speed. The pantograph starts to bounce and produces sparks which decreases the lifespan of the catenary. We are also looking into the size of the roller and the material.’

Tests

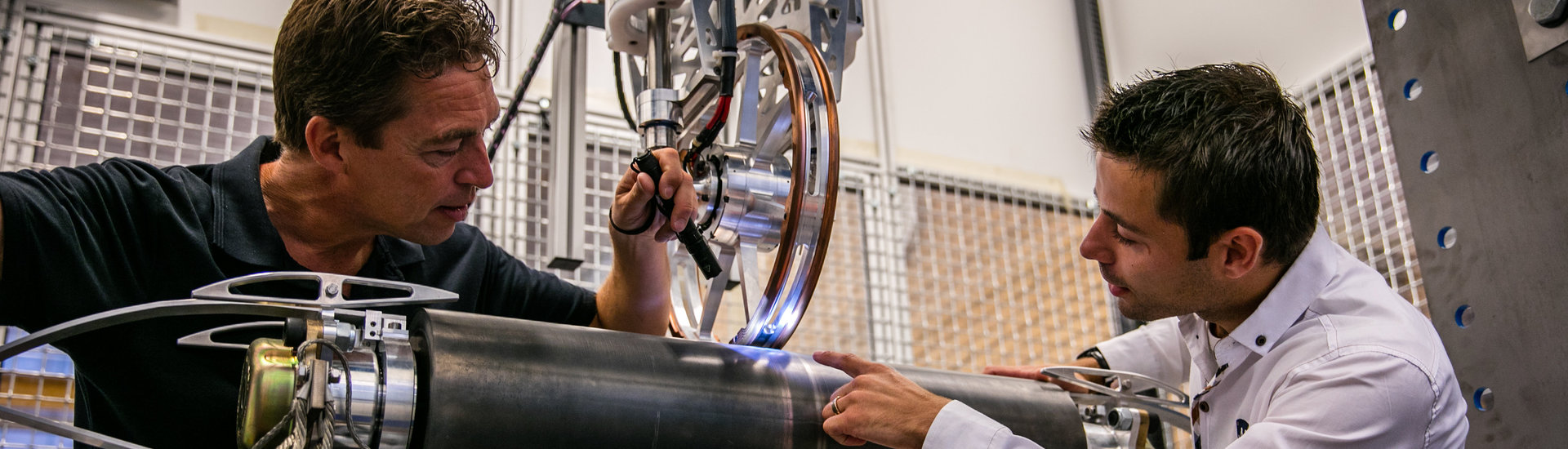

In the lab Van Veldhuizen and Moraal are testing the rolling pantograph with the aid of a catenary simulator. The pantograph prototype is put into the simulator and thinks it is interacting with a real overhead line which is represented by a wheel which moves over the rolling pantograph. ‘Up and down and from left to right: the wheel literally copies the vibrations of the catenary system,’ Van Veldhuizen explains. ‘The movements are computer generated. The simulator is very helpful at mapping out the problems we need to find solutions for. How to create the maximum contact between roller and overhead line, for instance, and how to deal with the forces that are being released in the process.’

Advantage

But why test in the lab when they can do it in the field? ‘Lab testing is repeatable, flexible and cheaper. It is also possible to test performance at high speed and other extremes which could never be done on a real track. Real life testing is an expensive business and much time and money would have to be spent on setting aside a designated track. The weather is a factor too. And if an overhead line should break during a test it would be a major inconvenience,’ Moraal says.

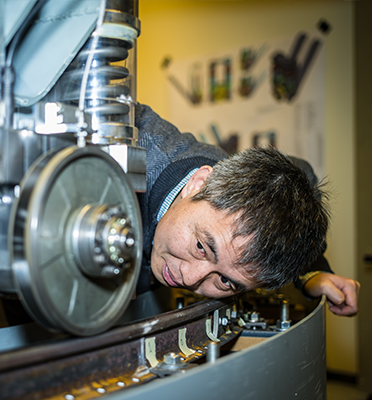

Building a simulator

Asked if the simulator was difficult to build Moraal says: ‘That is the reason I work at TU Delft. You begin with nothing and you end up creating something. You find inspiration in all corners of the world and look at what other people are doing. You find manufacturers and look for components to scale.’ This is where Delft’s Electronic and Mechanical Support Division came in. ‘They really helped us to develop the experimental testing environment. Sometimes you come up with things that don’t work. Then you have to think of an alternative.’