TU Delft and VDL ETG T&D research contactless wafer handling for better chip production

Every time the robotic arm picks up a wafer for placement in the chip machine, very small particles are generated which are harmful for the chip production process. The Faculty of Mechanical Engineering from TU Delft is working on new generation wafer handlers that can handle wafers without particle generation. One of the new aspects of these handlers is a method that transfers wafers without mechanical contact. A new collaboration between TU Delft and VDL ETG T&D aims to further develop this technique to ultimately make the chip production process more efficient.

The global demand for microchips is huge, driving the search for ways to improve the production process. In this regard, associate professor Ron van Ostayen's research group focuses on wafers. "You can think of them as the foundation for chips. Such a wafer goes through the lithography machine 80 to 100 times to build up the chips layer by layer," Van Ostayen explains. "If we manage to bring down the throughput time of wafers, the production capacity is expected to increase."

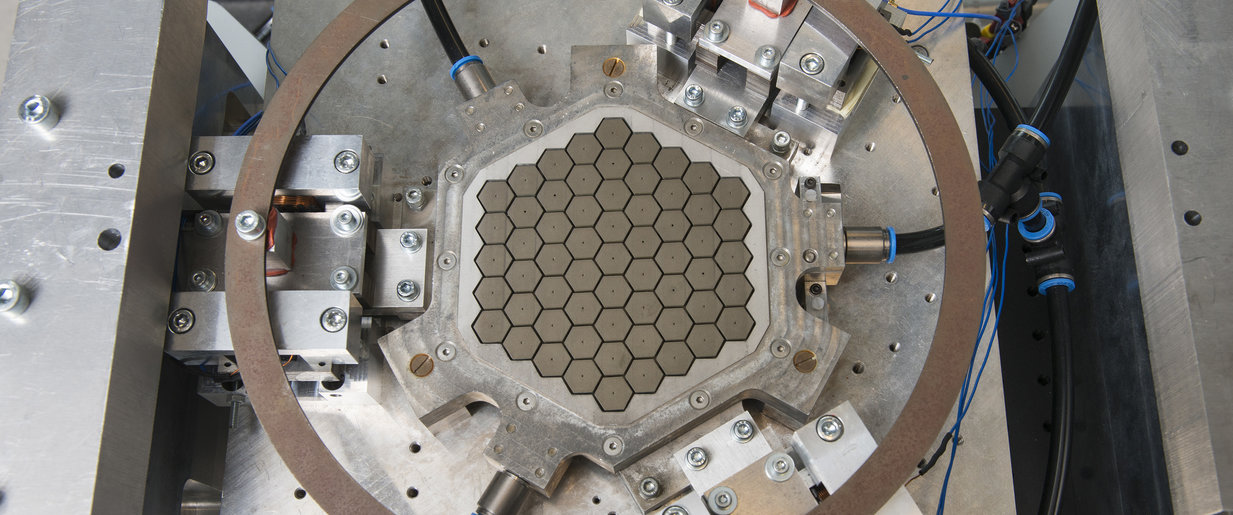

Floating wafers

The wafers, often made of silicon crystal, are transferred by a VDL ETG machine into lithography machines, such as those made by ASML. This is now done with a robotic arm that physically picks up the wafer. "We want to avoid this mechanical contact," says Van Ostayen. They do this by using an innovative concept. This allows the wafer to be handled contactlessly, which means that it actually floats through the machine. Van Ostayen's group has long been working on techniques to make this a reality. Because they can now use VDL ETG T&D's expertise, they hope that this technique will find its way into daily practice.

Reducing particle generation

Moving the wafer without contact will not always be possible or desired. Another question at the heart of this project is therefore: how to make the mechanical contact as friendly as possible? For this, the researchers are looking at new designs and material technologies. Professor Just Herder, Department of Precision & Microsystems Engineering, investigates the possibility of compliant mechanisms. In line with this, assistant professor Sid Kumar, Department of Materials Science & Engineering, is looking at the most suitable material for these compliant mechanisms. As the material has to meet many requirements, this is not that easy. Kumar is specifically looking at smart metamaterials. “Nitinol is a shape-memory alloy, sometimes called smart metal. It is an alloy that remembers its original shape and always returns to this shape after heating. Combining Nitinol with targeted structural design, we aim to create innovative smart metamaterials that leverage properties extending beyond those inherent to Nitinol alone."

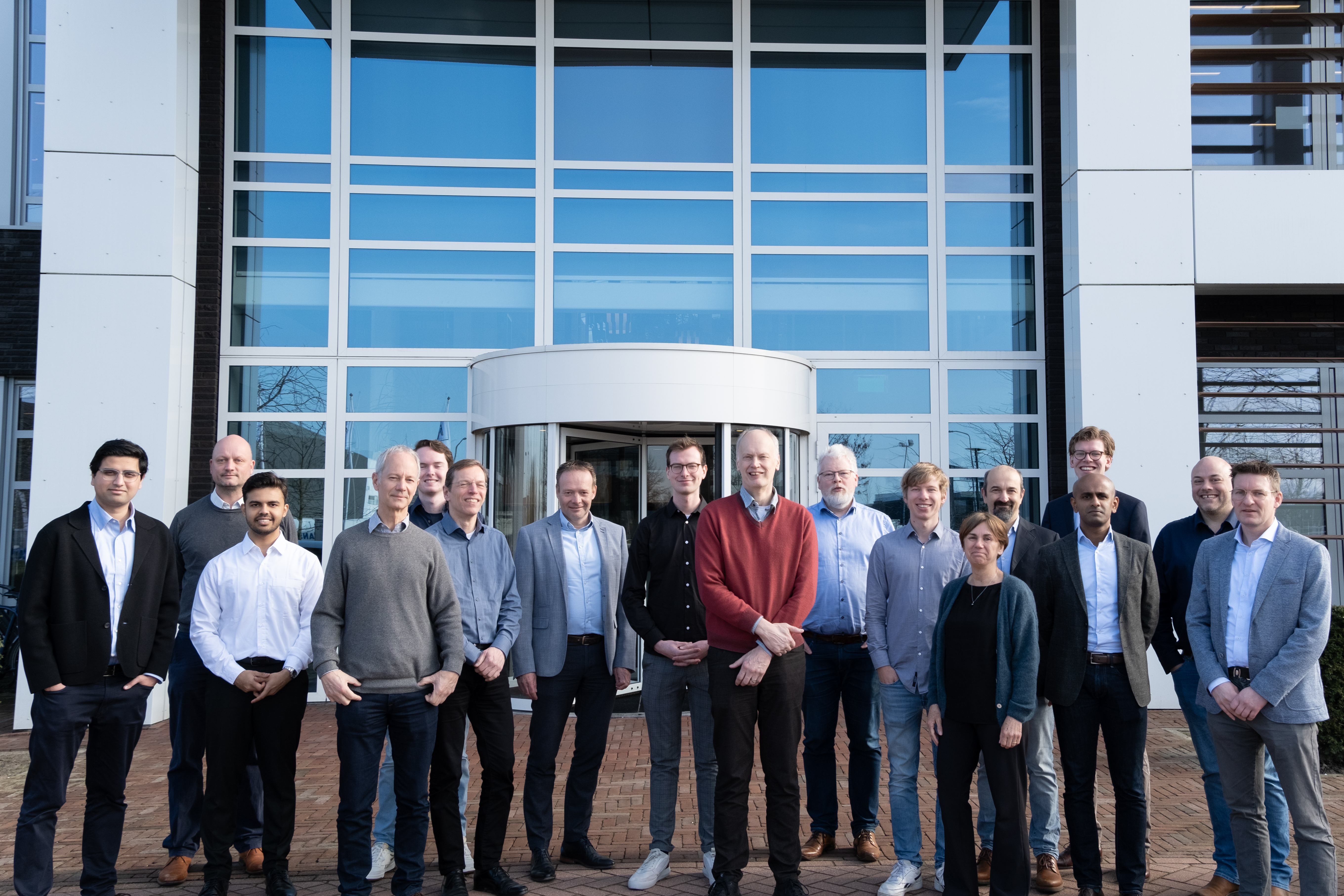

Valuable collaboration

This project marks the start of a new collaboration between TU Delft and VDL ETG T&D. "The intention is to start more projects together in the future," says Van Ostayen. "We can learn a lot from their expertise in precision manufacturing processes and design methods for high-tech systems. In addition, it is a valuable partner for student projects."

We are active in the field of High-Tech equipment development and engineering. To remain on the frontline of new technologies, we invest in a sustainable collaboration with the highly respected TU Delft.

Rob Boereboom, development manager VDL ETG T&D