TU Delft researchers discover new ultra strong material for microchip sensors

A material that doesn't just rival the strength of diamonds and graphene, but boasts a yield strength 10 times greater than Kevlar, renowned for its use in bulletproof vests.

Researchers at Delft University of Technology, led by assistant professor Richard Norte, have unveiled a remarkable new material with potential to impact the world of material science: amorphous silicon carbide (a-SiC). Beyond its exceptional strength, this material demonstrates mechanical properties crucial for vibration isolation on a microchip. Amorphous silicon carbide is therefore particularly suitable for making ultra-sensitive microchip sensors.

The range of potential applications is vast. From ultra-sensitive microchip sensors and advanced solar cells, to pioneering space exploration and DNA sequencing technologies. The advantages of this material's strength combined with its scalability make it exceptionally promising.

Ten medium-sized cars

“To better understand the crucial characteristic of "amorphous", think of most materials as being made up of atoms arranged in a regular pattern, like an intricately built Lego tower,” explains Norte. “These are termed as "crystalline" materials, like for example, a diamond. It has carbon atoms perfectly aligned, contributing to its famed hardness.”

However, amorphous materials are akin to a randomly piled set of Legos, where atoms lack consistent arrangement. But contrary to expectations, this randomisation doesn't result in fragility. In fact, amorphous silicon carbide is a testament to strength emerging from such randomness. The tensile strength of this new material is 10 GigaPascal (GPa). “To grasp what this means, imagine trying to stretch a piece of duct tape until it breaks. Now if you’d want to simulate the tensile stress equivalent to 10 GPa, you'd need to hang about ten medium-sized cars end-to-end off that strip before it breaks,” says Norte.

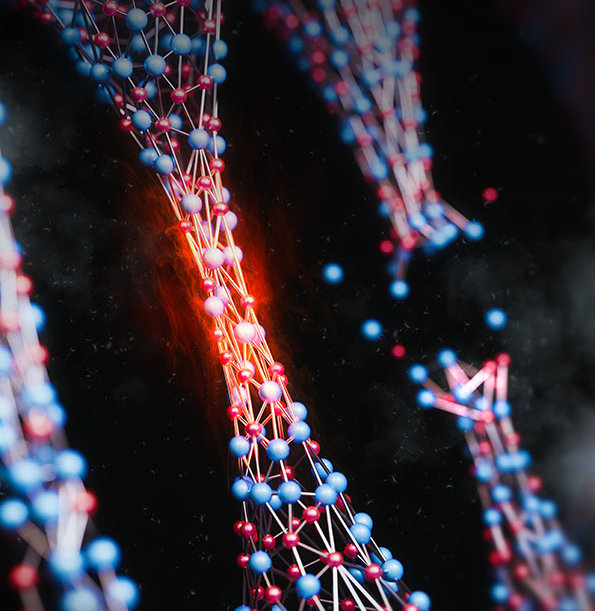

Nanostrings

The researchers adopted an innovative method to test this material's tensile strength. Instead of traditional methods that might introduce inaccuracies from the way the material is anchored, they turned to microchip technology. By growing the films of amorphous silicon carbide on a silicon substrate and suspending them, they leveraged the geometry of the nanostrings to induce high tensile forces. By fabricating many such structures with increasing tensile forces, they meticulously observed the point of breakage. This microchip-based approach not only ensures unprecedented precision but also paves the way for future material testing.

Why the focus on nanostrings? “Nanostrings are fundamental building blocks, the very foundation that can be used to construct more intricate suspended structures. Demonstrating high yield strength in a nanostring translates to showcasing strength in its most elemental form.”

From micro to macro

And what finally sets this material apart is its scalability. Graphene, a single layer of carbon atoms, is known for its impressive strength but is challenging to produce in large quantities. Diamonds, though immensely strong, are either rare in nature or costly to synthesize. Amorphous silicon carbide, on the other hand, can be produced at wafer scales, offering large sheets of this incredibly robust material.

“With amorphous silicon carbide's emergence, we're poised at the threshold of microchip research brimming with technological possibilities,” concludes Norte.

Read more about this research in Advanced Materials.

With amorphous silicon carbide's emergence, we're poised at the threshold of microchip research brimming with technological possibilities

Richard Norte