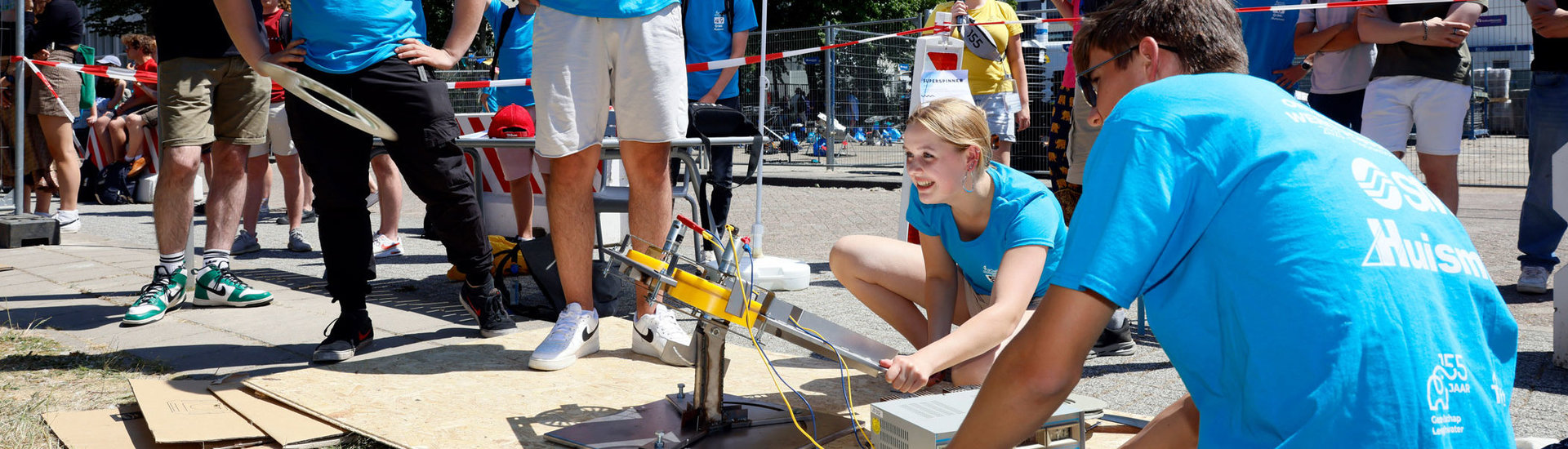

Mechanical engineering students display their Precision Disc Thrower

3, 2, 1… and there goes the disc of student team WB89, flying across the lawn. The device that launched the disc was five months in the making for the first-year mechanical engineering students. They designed and built it themselves. And today they got to show lecturers, fellow students and other members of the public their Precision Disc Thrower in action. Their design succeeded in throwing multiple discs into three different containers, and even managed to throw discs around an obstacle several times, which earned them bonus points. Ultimately, it also earned the students the right to call themselves the winners of the 2023 Mechanical Engineering Design Competition.

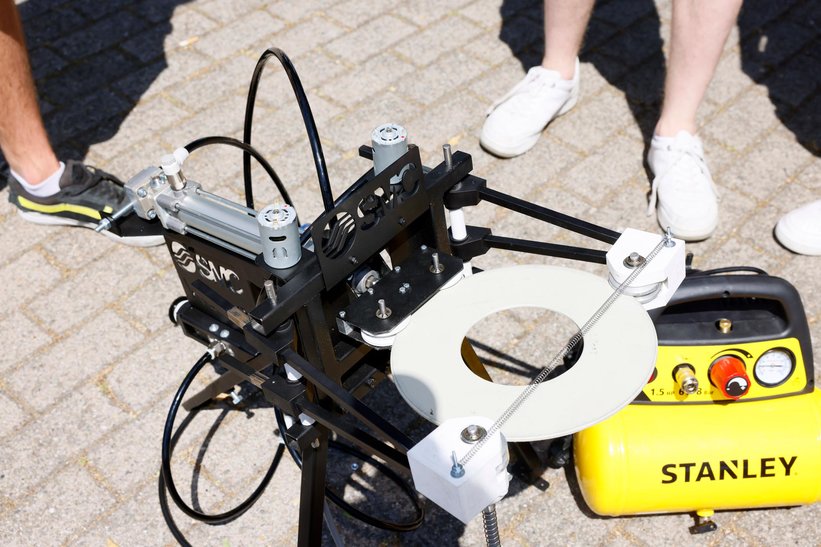

Designing a precision disc thrower is an ambitious challenge. ‘A lot goes into this kind of mechanical design. It has to have sufficient power, speed and precision. The rotation of the disc around its own axis – known as the gyroscopic effect – is also important,’ says Regine Vroom, coordinator of the design project. This requires a release mechanism or start button to set the disc in motion. An additional challenge was to throw the disc in a curve around an obstacle (a pole) before it lands in one of the containers.

Preliminaries

The first-year mechanical engineering students worked hard for two quarters to achieve this result. They all started with the same design brief, challenge points and conditions. Yet each team of students produced a different final design. They were already asked to submit a design report at an earlier stage, a 3D CAD model and technical assembly and production drawings. They chose the materials and components themselves. The students then had four four-hour periods to build the design in the workshop. At the end of the competition, the students analysed and evaluated the operation and possible improvements of the device one last time.

Different applications

A mechanical thrower has many potential uses. It could be used in a high-speed parcel sorter. A more socially-oriented example would be to use a drone to throw a lifebelt to a drowning person. A mechanical thrower would be much faster and more accurate than manually positioning and dropping a lifebuoy over a drowning person.

Green Award

The students in team WB11 may not have had the most powerful precision thrower, but they did have the most sustainable design. As a result, they won the Green Award. ‘We used Topology Optimisation, a method where the design programme optimises the layout of the material,’ says one of the students. ‘In simple terms, this means that unnecessary material is removed.’ In addition, all the materials used by the project group can be disassembled and reused.