Matthijs Langelaar appointed professor of Computational Design & Mechanics

Imagine an implant that holds vertebrae firmly in place while allowing patients enough freedom of movement. Or a light yet robust system that accelerates the production of computer chips. How do you find the best design for these kinds of innovations? Matthijs Langelaar believes the answer lies in algorithms. He was appointed professor at TU Delft on 5 July and is doing research into algorithms capable of solving these and many other mechanical design problems.

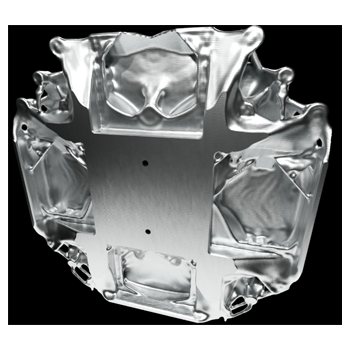

‘Algorithms generate remarkably surprising designs,’ says Matthijs Langelaar, who works in the Department of Precision and Microsystems Engineering. ‘Unlike human designers, who often start with basic shapes and proven concepts, algorithms are not bound by these constraints. This results in many more out-of-the-box solutions.’ Langelaar and his colleagues are developing algorithms and software that create new designs and optimise existing designs. This is known as computational design. Langelaar mainly applies this to mechanical parts made with 3D printers.

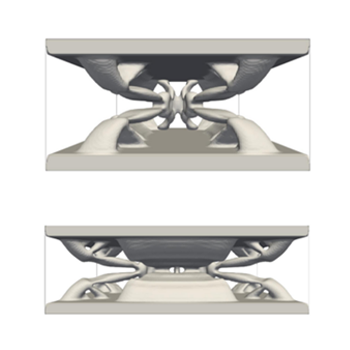

‘The emergence of additive manufacturing, or industrial 3D printing, signifies a major shift in the production of mechanical parts,’ Langelaar says. ‘Suddenly, we have the capacity to create a broader range of shapes, which is having a big impact on the design process.’ As a result, one of Langelaar’s areas of focus is to use computational design to fully exploit the flexibility of form offered by industrial 3D printing.

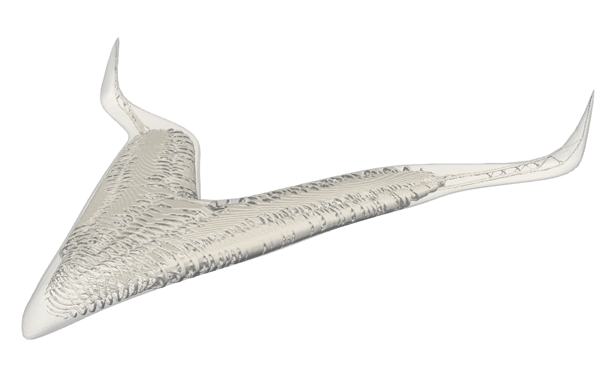

Another example is the design of a frame for the Flying V, a new type of aircraft developed by TU Delft. ‘This aircraft’s revolutionary shape requires a complete redesign to develop a light and rigid frame.’ Problems like these, which require optimisation, are perfect candidates for algorithmic solutions. While a team of designers might need weeks to calculate the most efficient design, an algorithm can do it in a day. But Langelaar would not describe it as a contest between the algorithm and the designer: ‘I see it more as a stimulating collaboration.’

Algorithm vs designer

The designer’s input is still necessary. The designer establishes the problem and defines the parameters for the design. Langelaar does a lot of research into the feasibility and functionality of the generated designs. ‘Additive manufacturing has many advantages, but also some limitations.’ For example, a part may overheat at certain points during the printing process, which could degrade the quality of the material. ‘By using simulations to predict exactly where this will happen, our algorithm can adjust the design at these critical points to avoid this problem.’ Langelaar and his team are developing methods that incorporate an increasing number of such design criteria.

Sustainable design

Langelaar will soon be looking at how to incorporate sustainability into the computational design process, an area he feels is currently not being given due attention. ‘It makes sense to me that we should consider not only the production phase but also the end-of-life cycle of objects. For example, are they easy to disassemble and recycle? And how can we take that into account in the design?’ Langelaar has even bigger plans for the future. ‘At present, our algorithms mainly design single-piece objects. As a next step, I would like to broaden the scope and develop techniques for automatically designing complete systems.’

Best lecturer

In addition to conducting research, Langelaar has enjoyed teaching in the undergraduate and graduate programmes in Mechanical Engineering for many years. And this has not gone unnoticed by his students. In fact, Langelaar is consistently voted best lecturer in the first year of Mechanical Engineering. ‘My approach is actually quite straightforward. I try to deliver lectures that I would have found fascinating myself. It is rewarding when the students appreciate that.’

Langelaar studied mechanical engineering at the University of Twente. Shortly thereafter, he came to Delft for his PhD. He has now been working at the PME department for approximately 22 years, but he also worked as a researcher in the United States, South Korea and Germany. Last year, he became head of the Computational Design and Mechanics research group.