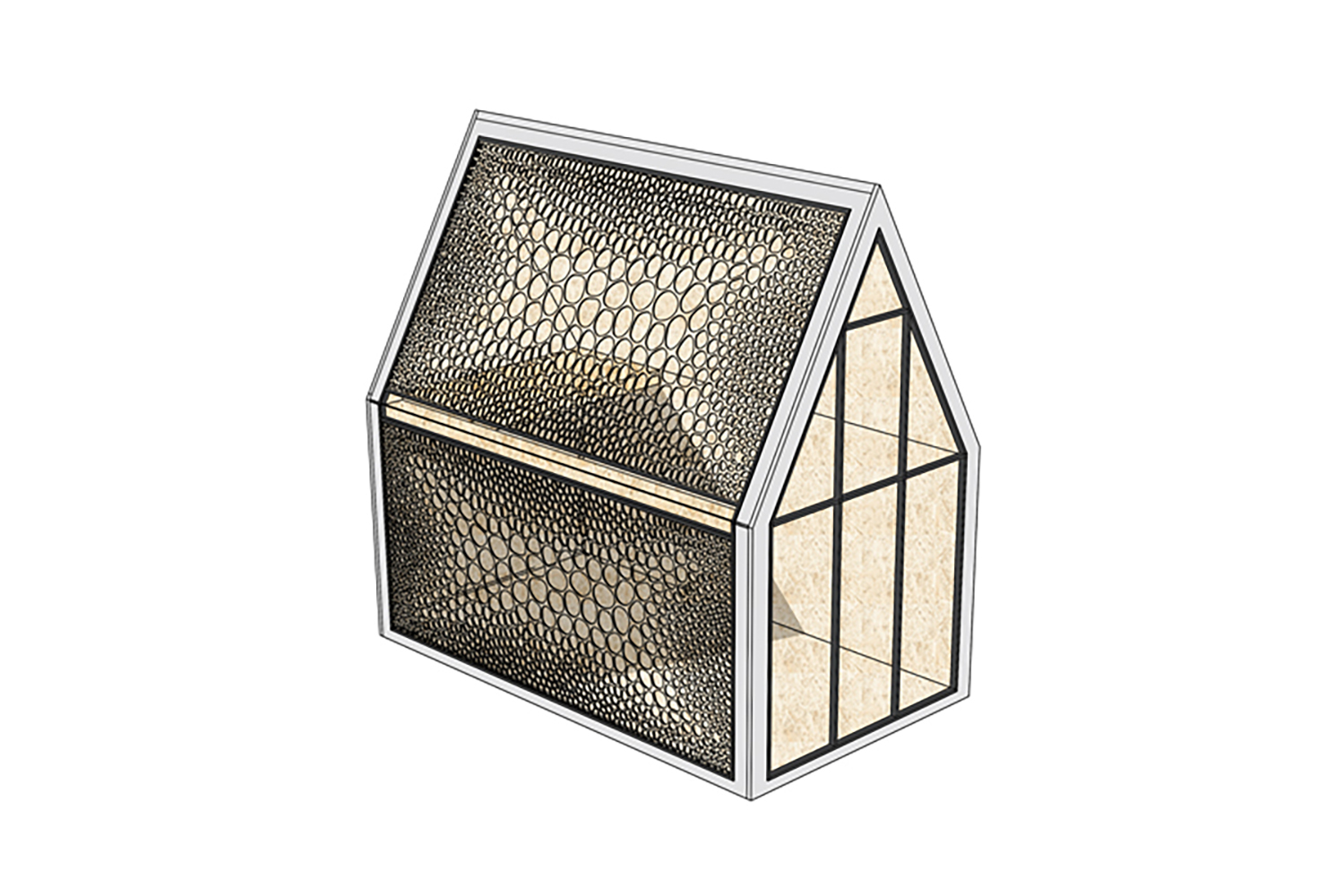

Thin Glass Composite Facade Panels with 3D-Printed Cores

Description

Thin glass – such as commonly applied for displays and touchscreen on electronic devices like smartphone and tablets – offers interesting characteristics for architectural applications. Due to its high strength and small thickness the glass can easily be bent in architecturally appealing curvatures, while the small thickness of the glass offers a significant weight reduction compared to traditional window glazing.

However, thin glass is typically too flexible to replace flat conventional window glazing on a one-to-one basis. The application of thinner glass, without additional measures, would result in too much deformation of the window glazing thereby exceeding the serviceability limit state requirements. Although this may not pose a direct safety treat, the large(r) deformation and potentially associated vibrations and optical deformations may cause discomfort and nuisance for building occupants.

Therefore, our research focuses on stiffening the thin glass panels with 3D-printed core materials. More specifically, composite panels consisting of thin chemically strengthened glass outer facings that are adhesively bonded to inner stiffening 3D-printed cores are generated. Benefit of doing so is that very lightweight yet strong and stiff façade panels are created.

The images shown are part of the MSc thesis of Tim Neeskens (supervisors: Christian Louter, Michela Turrin)