AR-P-6200 (CSAR62)

Tone | Positive | ||||||||||||||

Reference | All resist: https://www.allresist.com/portfolio-item/e-beam-resist-ar-p-6200-series-csar-62/ | ||||||||||||||

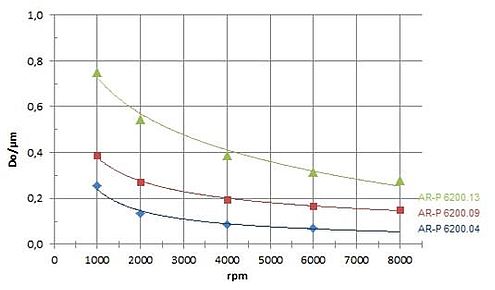

Spin coat |

| ||||||||||||||

Prebake | 150°C, 3 minutes on hotplate or 30 min on plate in oven | ||||||||||||||

Exposure | Clearance dose 180µC/cm² | ||||||||||||||

Development | X AR 6000-54/6 or pentylacetate for 60s | ||||||||||||||

Rinse | MIBK:IPA=1:1 for 60s, followed by IPA for 60s | ||||||||||||||

| or | |||||||||||||||

| o-xylene 5s, followed by IPA for 60s (this option reduces the amount of residues) |

In the table below you can find the etchrates for different plasmas:

| Etchrate gas 1 [nm/min] | Etchrate gas 2 [nm/min] | Etchrate gas 3 [nm/min] | Etchrate gas 4 [nm/min] |

CSAR62 | 66 | 93 | 29 | 54 |

PMMA | 104 | 133 | 44 | 71 |

ZEP 520A | 64 | 86 | 27.5 | 48 |

Gas 1: etcher F2, 20sccm O2, 40W, lowest pressure, bias -541V à -648V

Gas 2: etcher F2, 12.5sccm SF6, 10sccm He, 2.5sccm O2, 10µbar, 40W, bias -210V

Gas 3: etcher F1, 50sccm CHF3, 2.5sscm O2, 8.6µbar, 50W, bias -442V

Gas 4: etcher F1, 50sccm CHF3, 2.5sccm O2, 50µbar, 100W, bias -613V