Research

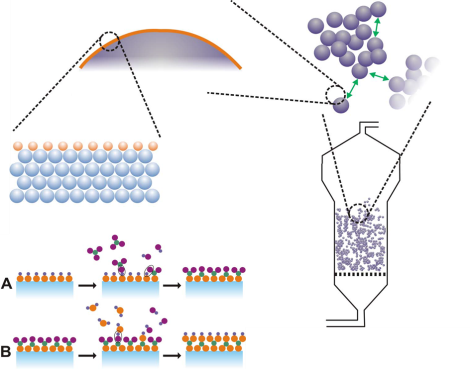

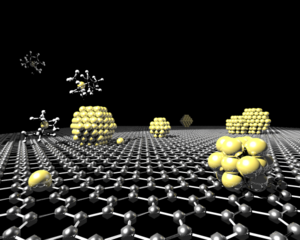

Our group works on projects in the field of chemical reaction engineering and particle technology. The current focus is on scalable processes to manufacture nanostructured materials. We use making nanostructured materials by methods such as atomic layer deposition and molecular layer deposition. We have developed a continuous process to coat particle using atomic layer deposition. Using small-angle neutron scattering combined with modelling work, we have revealed the multi-fractal structure of nanoparticle agglomerates in the gas phase. This fundamental knowledge puts us in the position to take the next leap towards to integrated synthesis and functionalization of advanced solid materials, and enable a variety of relevant applications, such as catalysis, phosphor particles for LEDs, and controlled-release medicines.

-

The research is focused on utilizing the sun’s energy to clean water – so called photocatalysis. In this PhD project new photocatalytic materials will be developed using a gas phase deposition technique (Atomic Layer Deposition). Furthermore, the newly developed materials will be implemented in a photoreactor at a later stage which will be tested in real conditions in Vietnam.

-

Understanding and Controlling Aggregation Phenomena in Atomic Layer Deposition of Nanostructures on Bulk Quantities of Nanopowders.

-

Many of the today's commonly-used ALD processes rely on the use of expensive and dangerous precursors. Moreover, moving from the ALD processes used in lab scale to the production scale requires alternative reactor designs and precursors. In collaboration with several other world-leading experts (in industry and academia), we aim to design safe and large-scale ALD processes. As a student, you will be working on developing these ALD processes and testing the applications of the deposited films in different systems.

-

This project – funded by AstraZeneca (a leading multinational pharmaceutical company) – aims at developing gas-phase coating processes on pharmaceutical particles in fluidized bed reactors to (i) control drug release, (ii) improve bulk powder properties (e.g., flowability and dispersibility) and (iii) provide physicochemical stabilization of drug particles (e.g. stabilization to moisture).

-

Luminescent materials (phosphors) are of great importance for various applications, such as phosphor-converted white LEDs and smart-highway lighting, but many phosphors suffer from thermal degradation as a result of oxidation. In this research, atomic layer deposition in a fluidized bed reactor is used with the intention to coat the phosphor particles in a controlled way with a thin, closed layer that will protect the phosphor against degradation and enhance its luminescence properties.

-

177Lu is used as a radio therapeutic in Peptide Receptor Radionuclide Therapy (PRRT). Currently, the 177Lu is produced either via irradiation of 176Lu or 176Yb with neutrons. Because of the 6.7 days half life of 177Lu treatment facilities must be weekly supplied with radioactive lutetium in order to maintain normal operation. A generator based on the long lived 177mLu could decrease the dependency on nuclear reactors and increase the shipping distance from the currently available distribution locations.

Aim: Develop a generator which gives ultra-high specific activity 177Lu by finding physical proof for bond rupture to happen with 177mLu/177Lu, study multiple carries, including chelators, determine elution efficiencies of 177Lu etc.