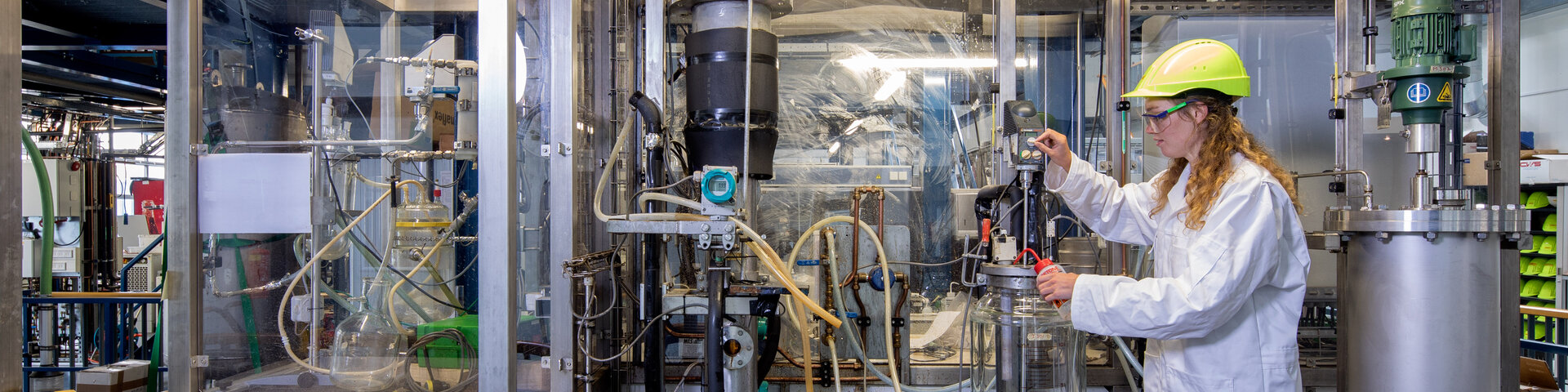

TU Delft Process & Product Technology Institute (Pro2Tech) is the research incubator for process and product technologies at TU Delft. It reinforces the coherence and collaboration between process technology researchers working at TU Delft and our academic and industrial partners worldwide.

Pro2Tech | TU Delft Process & Product Technology Institute

Pro2Tech | Food and Pharma

Lees meer Pro2Tech | Food and Pharma

Pro2Tech | Energy

Lees meer Pro2Tech | Energy

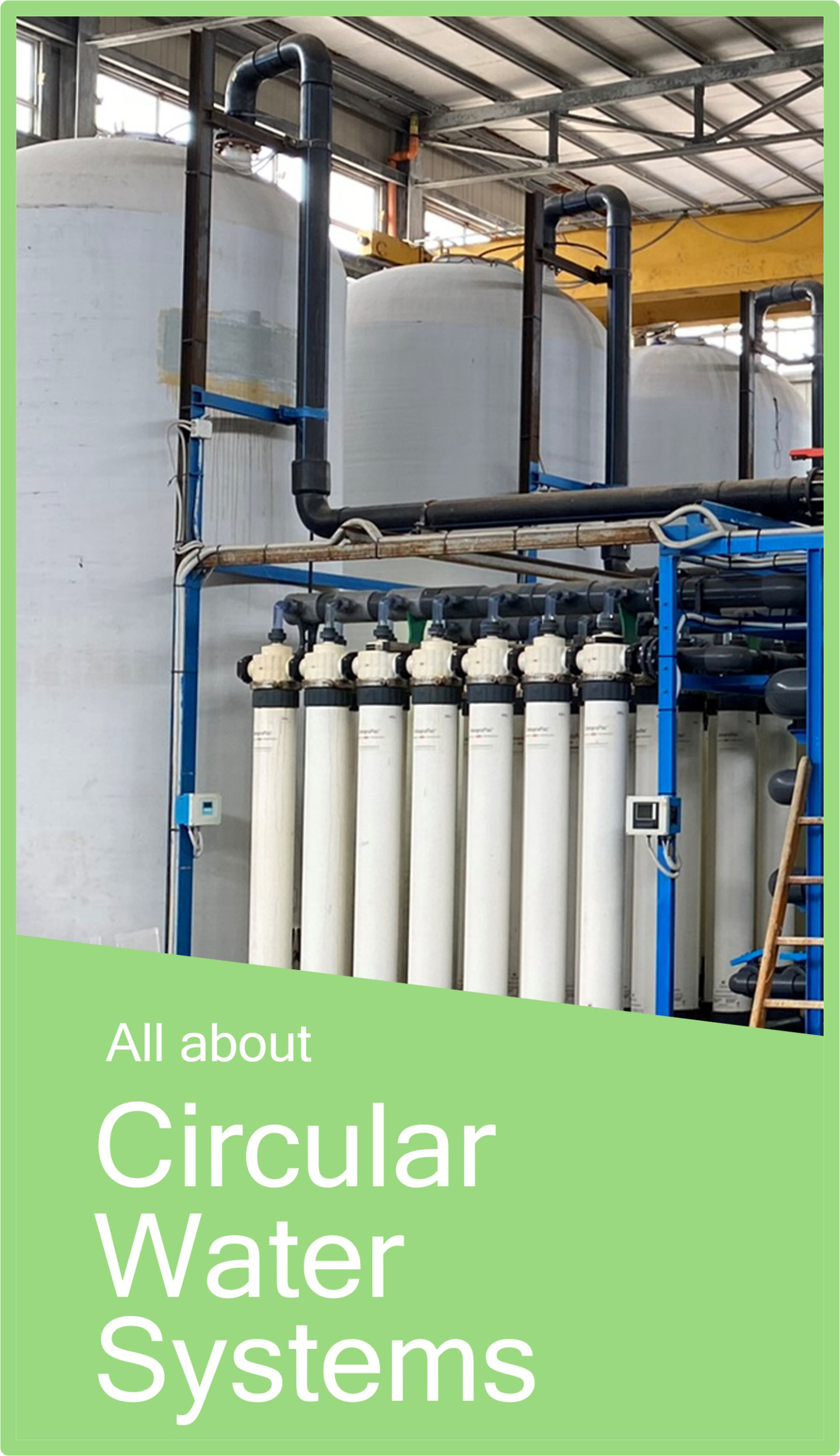

Pro2Tech | Water Processing

Lees meer Pro2Tech | Water Processing

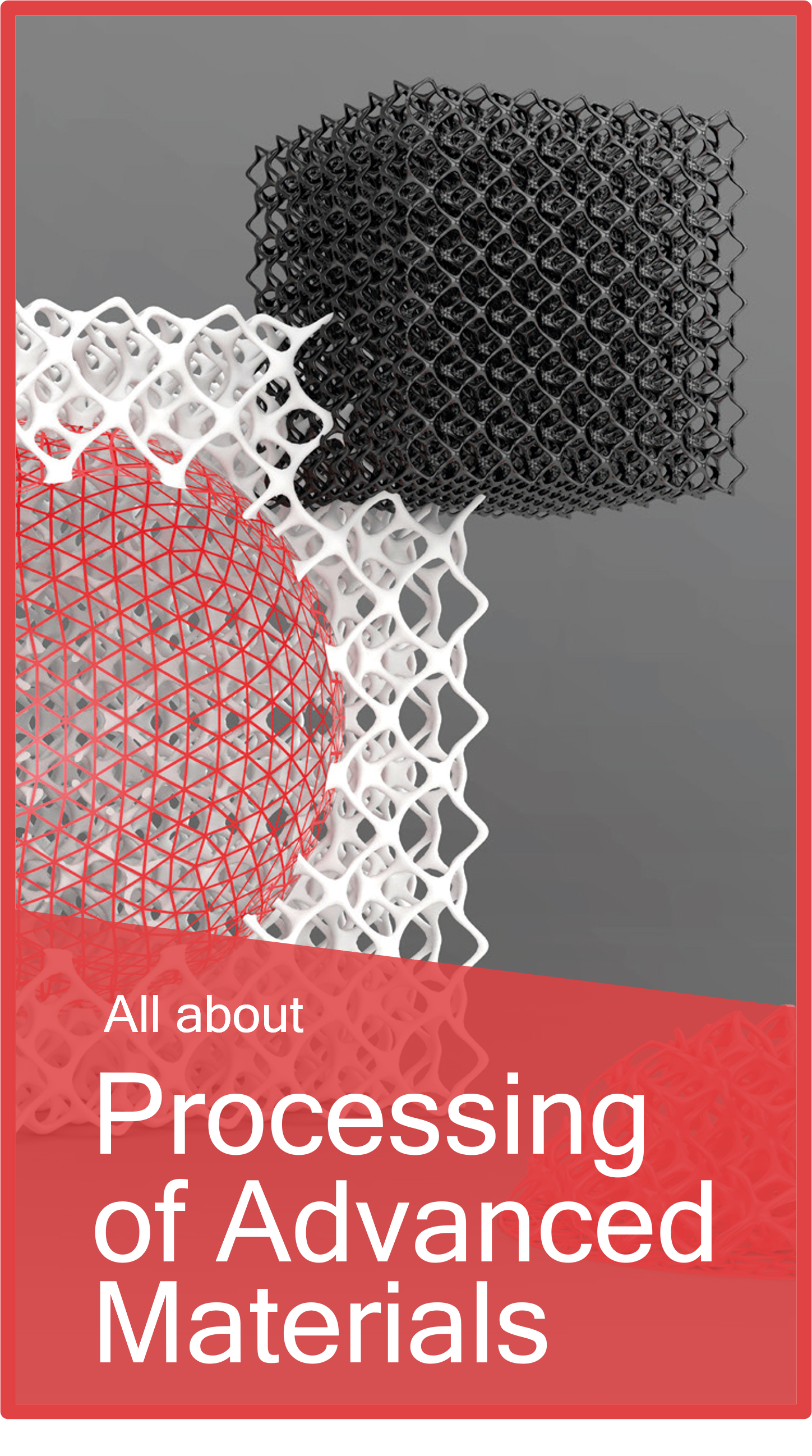

Pro2Tech | Processing of Advanced Materials

Lees meer Pro2Tech | Processing of Advanced Materials

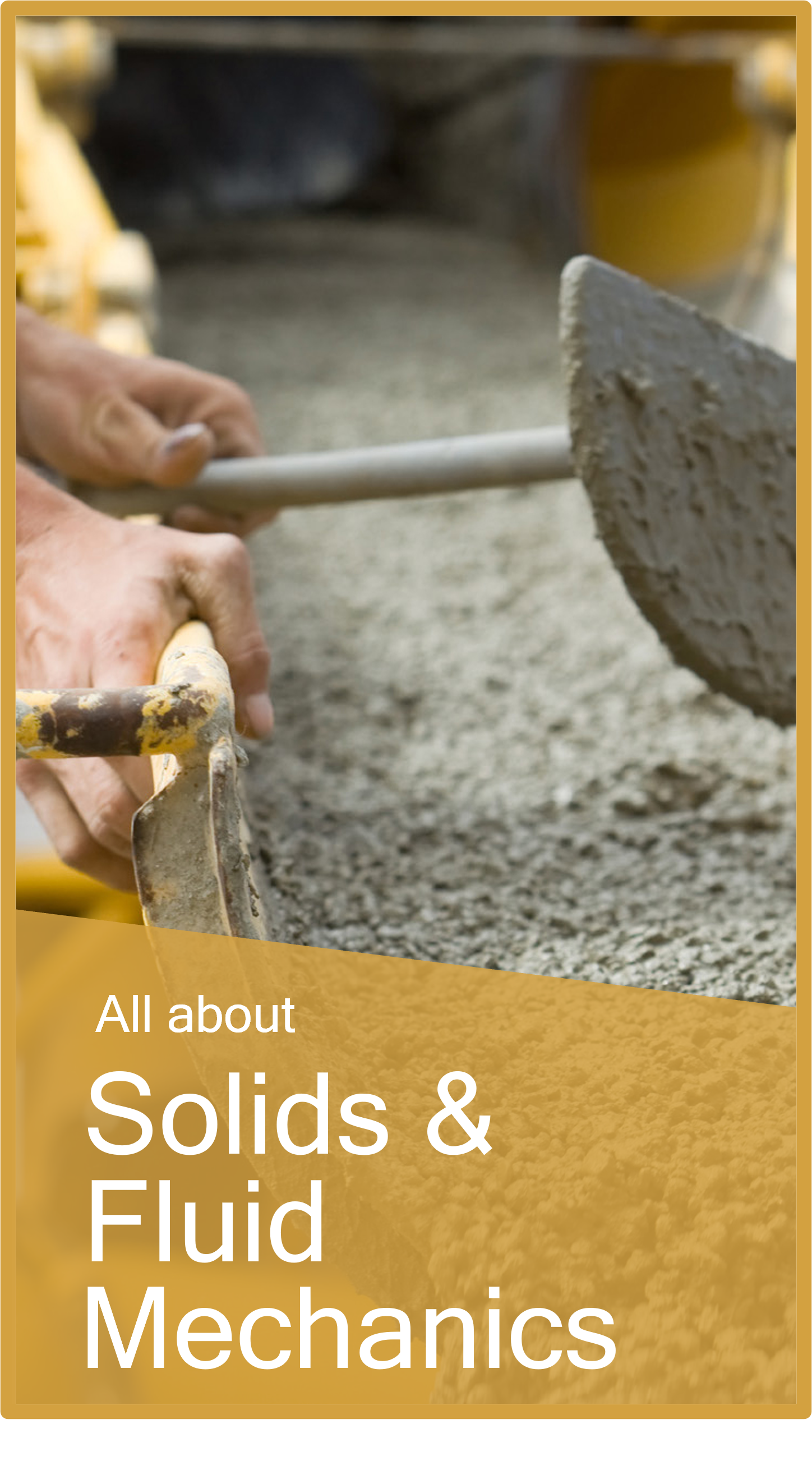

Pro2Tech | Solids & Fluid Mechanics

Lees meer Pro2Tech | Solids & Fluid Mechanics

Item 1

van

6